20, 55, 40, 50 specifications

Unigreen is a prominent name in the agricultural machinery sector, specializing in high-performance sprayers designed for precision farming and crop protection. Among its range, the Unigreen 20, 40, 55, and 50 models stand out due to their innovative features and advanced technologies, making them ideal choices for farmers seeking efficiency and effectiveness in their spraying operations.The Unigreen 20 is recognized for its compact design, making it an excellent choice for smaller farms or applications requiring maneuverability in tight spaces. It is equipped with a robust tank and a user-friendly control system that allows operators to monitor and adjust spraying settings on the fly, ensuring optimal application rates and minimizing waste.

Moving up the range, the Unigreen 40 model boasts a larger capacity tank, making it suitable for medium-sized operations. One of its main features is the advanced hydraulic suspension system, which ensures stability and uniform application even on uneven terrain. This model also integrates GPS technology, enabling precision mapping of fields to guarantee that every area receives the appropriate treatment.

The Unigreen 55 further expands on these capabilities with enhanced power and efficiency. It features a high-performance pump system that delivers consistent spraying pressure, allowing for a wider coverage area. The sprayer’s adjustable boom technology is designed to reduce drift and increase accuracy, which is essential in environmentally sensitive areas.

Lastly, the Unigreen 50 combines features from the preceding models and introduces cutting-edge automation. This model includes smart sensors that detect plant health, providing real-time feedback on the most effective solutions to apply. The sprayer is also compatible with precision agriculture technologies, such as variable rate application, which optimizes inputs based on specific field conditions.

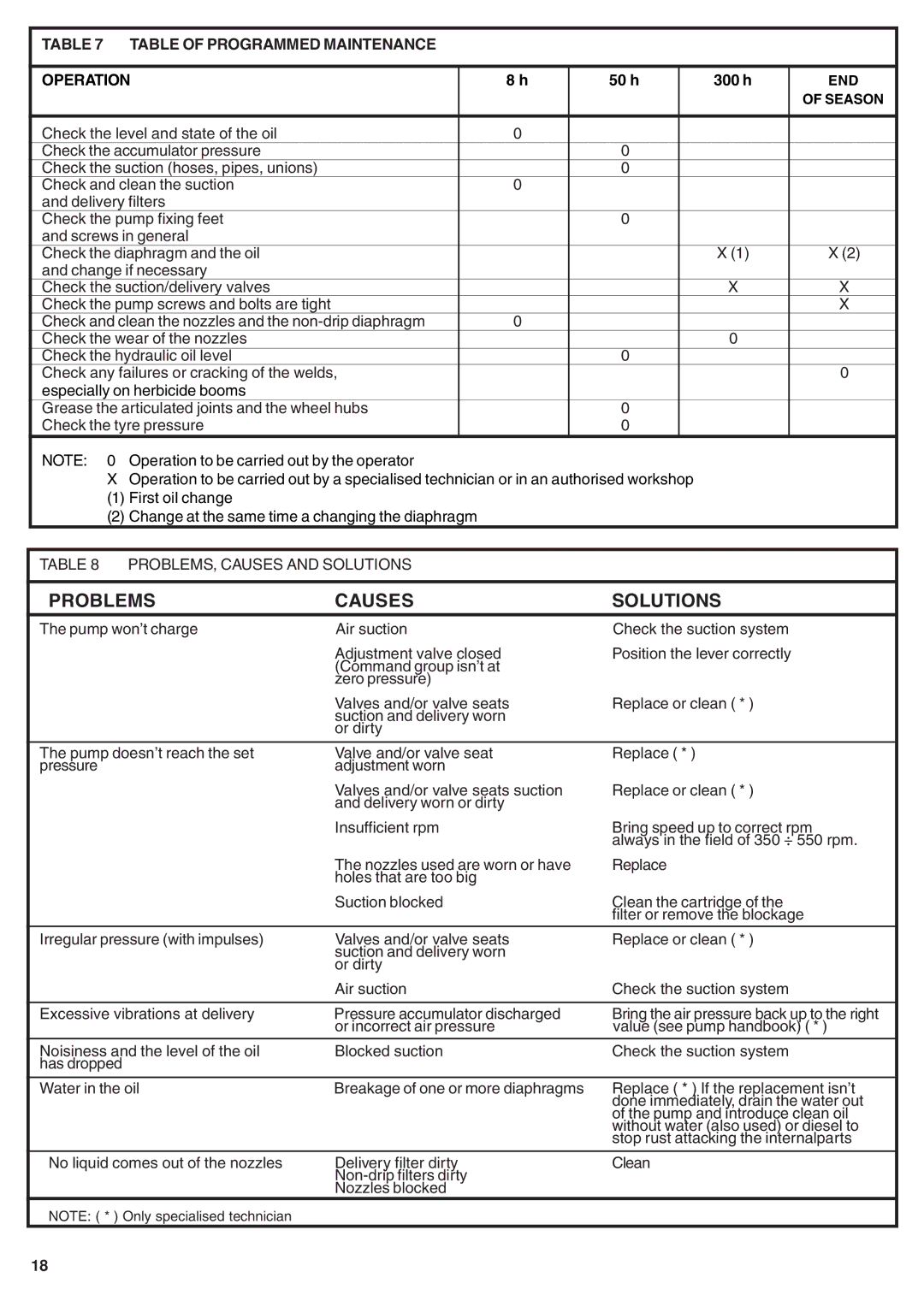

Each model from Unigreen is constructed with durability in mind, utilizing high-quality materials to withstand the rigors of agricultural use. The user-centric designs ensure ease of operation and maintenance across the range. With options to suit various farming needs, the Unigreen 20, 40, 55, and 50 models exemplify the convergence of technology and practicality in modern agriculture, making them vital assets for farmers striving for sustainability and productivity in their operations.