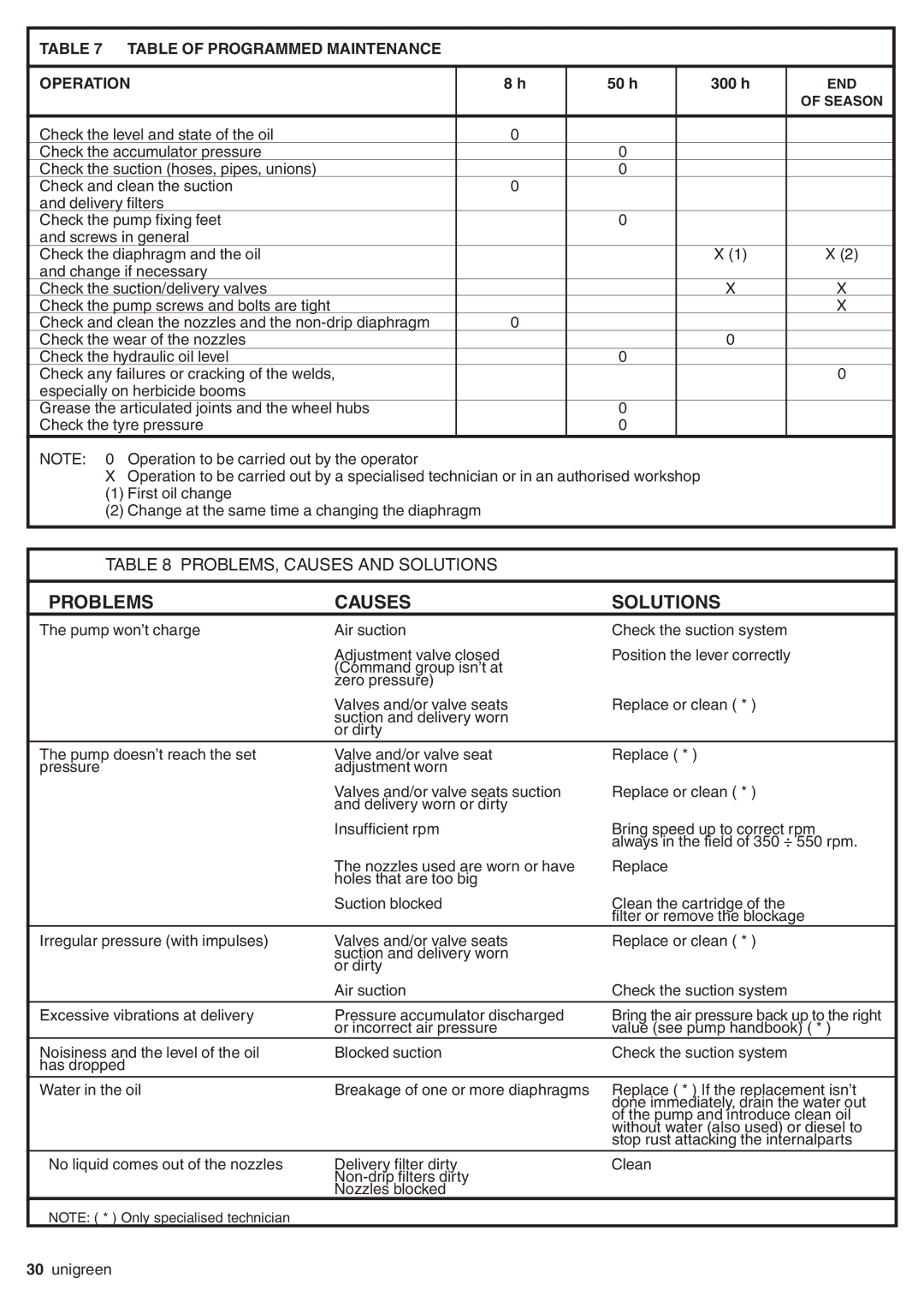

TABLE 7 TABLE OF PROGRAMMED MAINTENANCE

OPERATION | 8 h | 50 h | 300 h | END |

|

|

|

| OF SEASON |

|

|

|

|

|

Check the level and state of the oil | 0 |

|

|

|

Check the accumulator pressure |

| 0 |

|

|

Check the suction (hoses, pipes, unions) |

| 0 |

|

|

Check and clean the suction | 0 |

|

|

|

and delivery filters |

|

|

|

|

Check the pump fixing feet |

| 0 |

|

|

and screws in general |

|

|

|

|

Check the diaphragm and the oil |

|

| X (1) | X (2) |

and change if necessary |

|

|

|

|

Check the suction/delivery valves |

|

| X | X |

Check the pump screws and bolts are tight |

|

|

| X |

Check and clean the nozzles and the | 0 |

|

|

|

Check the wear of the nozzles |

|

| 0 |

|

Check the hydraulic oil level |

| 0 |

|

|

Check any failures or cracking of the welds, |

|

|

| 0 |

especially on herbicide booms |

|

|

|

|

Grease the articulated joints and the wheel hubs |

| 0 |

|

|

Check the tyre pressure |

| 0 |

|

|

NOTE: 0 Operation to be carried out by the operator |

|

|

|

|

X Operation to be carried out by a specialised technician or in an authorised workshop

(1) First oil change

(2) Change at the same time a changing the diaphragm

TABLE 8 PROBLEMS, CAUSES AND SOLUTIONS

PROBLEMS | CAUSES | SOLUTIONS |

The pump won’t charge | Air suction | Check the suction system |

| Adjustment valve closed | Position the lever correctly |

| (Command group isn’t at |

|

| zero pressure) |

|

| Valves and/or valve seats | Replace or clean ( * ) |

| suction and delivery worn |

|

| or dirty |

|

The pump doesn’t reach the set | Valve and/or valve seat | Replace ( * ) |

pressure | adjustment worn |

|

| Valves and/or valve seats suction | Replace or clean ( * ) |

| and delivery worn or dirty |

|

| Insufficient rpm | Bring speed up to correct rpm |

|

| always in the field of 350 ÷ 550 rpm. |

| The nozzles used are worn or have | Replace |

| holes that are too big |

|

| Suction blocked | Clean the cartridge of the |

|

| filter or remove the blockage |

Irregular pressure (with impulses) | Valves and/or valve seats | Replace or clean ( * ) |

| suction and delivery worn |

|

| or dirty |

|

| Air suction | Check the suction system |

|

|

|

Excessive vibrations at delivery | Pressure accumulator discharged | Bring the air pressure back up to the right |

| or incorrect air pressure | value (see pump handbook) ( * ) |

Noisiness and the level of the oil | Blocked suction | Check the suction system |

has dropped |

|

|

Water in the oil | Breakage of one or more diaphragms | Replace ( * ) If the replacement isn’t |

|

| done immediately, drain the water out |

|

| of the pump and introduce clean oil |

|

| without water (also used) or diesel to |

|

| stop rust attacking the internalparts |

No liquid comes out of the nozzles | Delivery filter dirty | Clean |

|

| |

| Nozzles blocked |

|

NOTE: ( * ) Only specialised technician |

|

|

30unigreen