5BLOWER GROUP

All the mistblowers have a high speed fan rotor. You must take great care and beware of the effects that this can provoke: such as the aspiration and projection of foreign bodies which, although of a small size, can be very dangerous especially for the eyes and face.

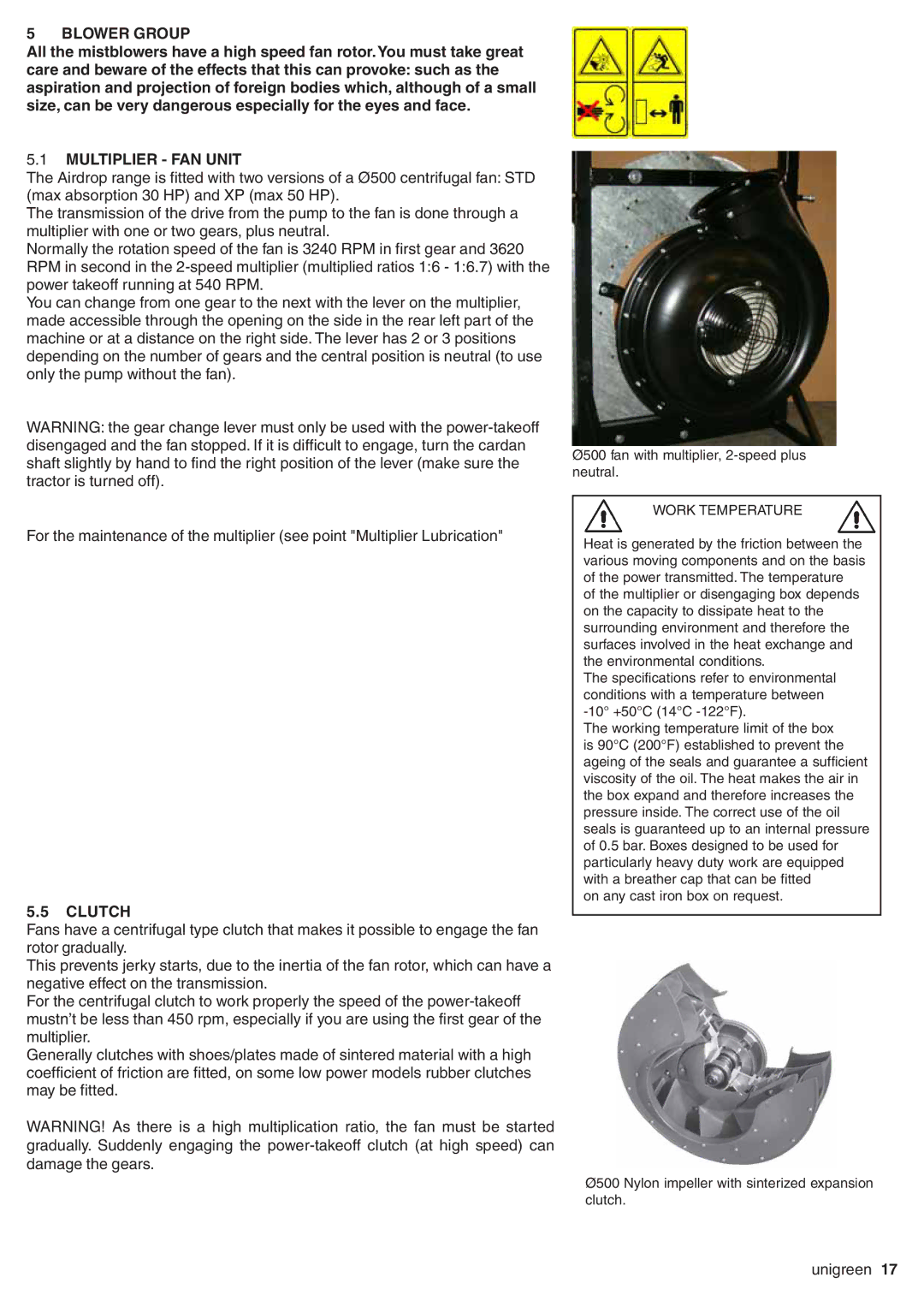

5.1MULTIPLIER - FAN UNIT

The Airdrop range is fitted with two versions of a Ø500 centrifugal fan: STD (max absorption 30 HP) and XP (max 50 HP).

The transmission of the drive from the pump to the fan is done through a multiplier with one or two gears, plus neutral.

Normally the rotation speed of the fan is 3240 RPM in first gear and 3620 RPM in second in the

You can change from one gear to the next with the lever on the multiplier, made accessible through the opening on the side in the rear left part of the machine or at a distance on the right side. The lever has 2 or 3 positions depending on the number of gears and the central position is neutral (to use only the pump without the fan).

WARNING: the gear change lever must only be used with the

Ø500 fan with multiplier,

For the maintenance of the multiplier (see point "Multiplier Lubrication"

5.5CLUTCH

Fans have a centrifugal type clutch that makes it possible to engage the fan rotor gradually.

This prevents jerky starts, due to the inertia of the fan rotor, which can have a negative effect on the transmission.

For the centrifugal clutch to work properly the speed of the

Generally clutches with shoes/plates made of sintered material with a high coefficient of friction are fitted, on some low power models rubber clutches may be fitted.

WARNING! As there is a high multiplication ratio, the fan must be started gradually. Suddenly engaging the

WORK TEMPERATURE

Heat is generated by the friction between the various moving components and on the basis of the power transmitted. The temperature

of the multiplier or disengaging box depends on the capacity to dissipate heat to the surrounding environment and therefore the surfaces involved in the heat exchange and the environmental conditions.

The specifications refer to environmental conditions with a temperature between

The working temperature limit of the box is 90°C (200°F) established to prevent the ageing of the seals and guarantee a sufficient viscosity of the oil. The heat makes the air in the box expand and therefore increases the pressure inside. The correct use of the oil seals is guaranteed up to an internal pressure of 0.5 bar. Boxes designed to be used for particularly heavy duty work are equipped with a breather cap that can be fitted

on any cast iron box on request.

Ø500 Nylon impeller with sinterized expansion clutch.

unigreen 17