¨

3

Sahara Series Automatic

Bilge Pumps

4505 / 4507 / 4511 Installation Instructions

SAVE THESE INSTRUCTIONS

Form Number 69370 Rev. C |

This product carries the standard Attwood

See www.attwoodmarine.com or Product Catalog for details.

CAUTION:

Read all instructions carefully before installing and using this product.

This pump is sealed and, therefore, submersible. However, the electrical wire connections must not be submerged. For extra protection, coat the butt joints and adjacent wire ends liberally with liquid electrical tape such as MDR¨ or Starbrite¨.

Specifications

|

|

| ABYC Specifications | ISO Specifications | ||||

|

|

|

|

| ||||

|

|

| (GPH=Gallons Per Hour) | (LPH=Liters Per Hour) | ||||

|

|

| 0 ft. | 3.3 ft. | 6.7 ft. | 10kPa | 20kPa |

|

|

|

| Head | Head | Head | Head | Head | Max Head |

Part |

| Amp | GPH/ | GPH/ | GPH/ | LPH/ | LPH/ | (ft.@13.6v/ |

Num. | Model | Fuse | amps | amps | amps | amps | amps | kPa@12v) |

4505 | S500 | 2.0 | 500/1.5 | 350/1.4 | 200/1.4 | 1136/1.2 | 598/1.2 | 9'/24 |

4507 | S750 | 5.0 | 750/3.0 | 625/2.8 | 450/2.8 | 1817/2.5 | 1306/2.5 | 16'/36 |

4511 | S1100 | 6.0 | 1100/4.0 | 970/3.8 | 750/3.8 | 3104/3.3 | 2328/3.3 | 11'7"/28 |

![]() WARNING: To prevent injury, always disconnect the power source when installing or servicing any electrical product.

WARNING: To prevent injury, always disconnect the power source when installing or servicing any electrical product.

DO NOT use pump to remove gasoline, oil or other flammable liquids.

Always use the fuse amperage rating specified for your pump model. Failure to do so could result in serious personal injury or fire hazards.

Attwood bilge pumps are designed to exhaust STANDING WATER ONLY. They are not intended to prevent rapid accumulation of

REQUIRED MATERIALS

¥Hose and

Sahara Model 4505 and 4507–

3/4" I.D. hose: Attwood No. 4199 (includes 2 clamps)

3/4" I.D.

Sahara Model 4511–

¥Two (2) hose clamps suitable for (3/4" or

¥AUTO/OFF/MANUAL

¥

¥Three (3) stainless steel #6 x 1/2"

¥Four (4) wire

¥Two (2) insulated spade terminal connectors for

¥Suitable means to make electrical connections waterproof.

¥Cordless drill.

¥Screwdriver.

OPTIONAL MATERIALS

¥

¥Waterproof adhesive (epoxy, silicone adhesive, or fiberglass resin) to mount block.

¥

PUMP MOUNTING INSTRUCTIONS

![]() WARNING: Remove the pump mounting base (See Figure 3). Remove the foam block that supports the float during shipping. Failure to do this prevents the pump from starting when water

WARNING: Remove the pump mounting base (See Figure 3). Remove the foam block that supports the float during shipping. Failure to do this prevents the pump from starting when water

is present.

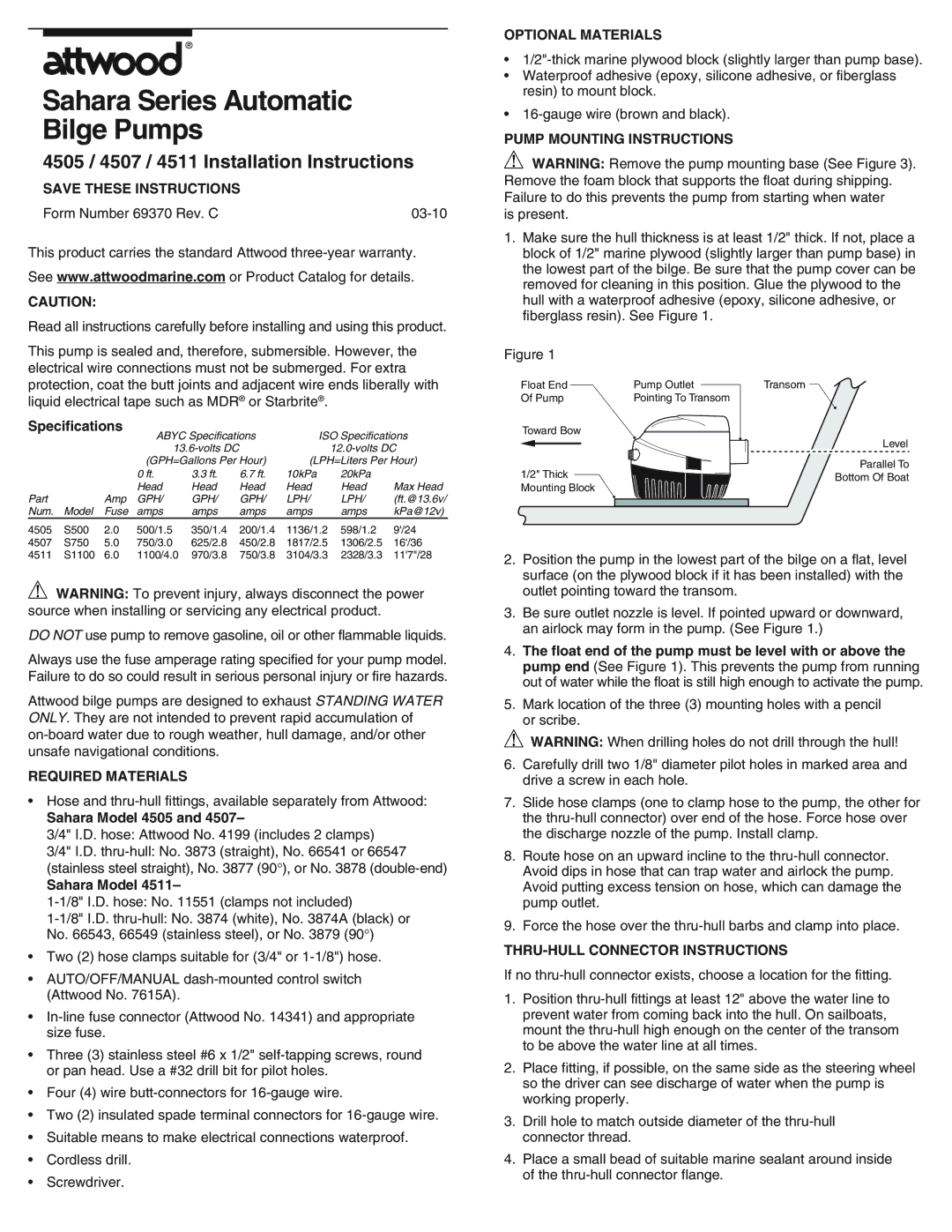

1.Make sure the hull thickness is at least 1/2" thick. If not, place a block of 1/2" marine plywood (slightly larger than pump base) in the lowest part of the bilge. Be sure that the pump cover can be removed for cleaning in this position. Glue the plywood to the hull with a waterproof adhesive (epoxy, silicone adhesive, or fiberglass resin). See Figure 1.

Figure 1

Float End | Pump Outlet | Transom |

Of Pump | Pointing To Transom |

|

Toward Bow |

|

|

|

| Level |

1/2" Thick |

| Parallel To |

| Bottom Of Boat | |

Mounting Block |

|

|

2.Position the pump in the lowest part of the bilge on a flat, level surface (on the plywood block if it has been installed) with the outlet pointing toward the transom.

3.Be sure outlet nozzle is level. If pointed upward or downward, an airlock may form in the pump. (See Figure 1.)

4.The float end of the pump must be level with or above the pump end (See Figure 1). This prevents the pump from running out of water while the float is still high enough to activate the pump.

5.Mark location of the three (3) mounting holes with a pencil or scribe.

![]() WARNING: When drilling holes do not drill through the hull!

WARNING: When drilling holes do not drill through the hull!

6.Carefully drill two 1/8" diameter pilot holes in marked area and drive a screw in each hole.

7.Slide hose clamps (one to clamp hose to the pump, the other for the

8.Route hose on an upward incline to the

9.Force the hose over the

THRU-HULL CONNECTOR INSTRUCTIONS

If no

1.Position

2.Place fitting, if possible, on the same side as the steering wheel so the driver can see discharge of water when the pump is working properly.

3.Drill hole to match outside diameter of the

4.Place a small bead of suitable marine sealant around inside of the