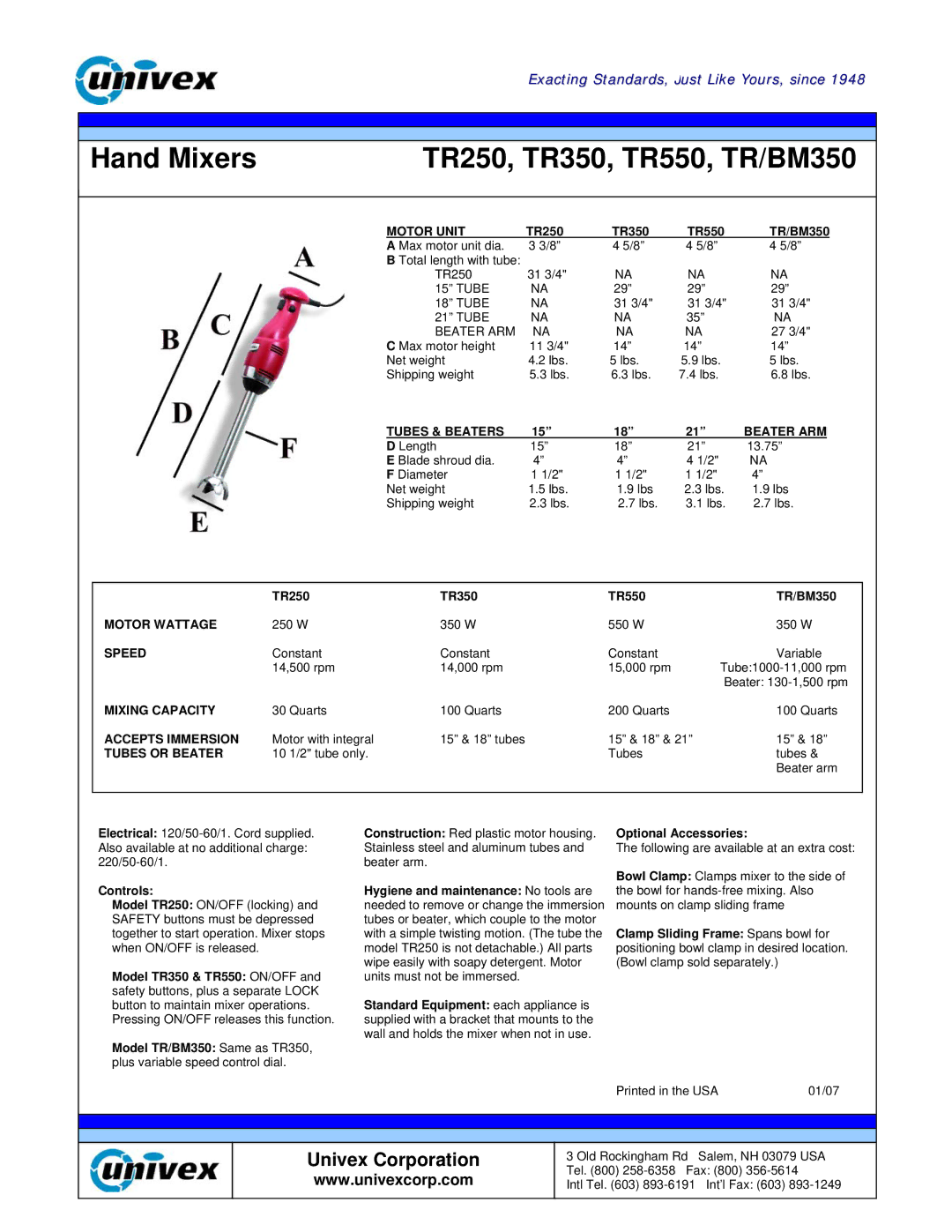

TR/BM350, TR350, TR550 specifications

Univex has made a significant impact in the food processing industry with its innovative equipment, particularly the TR series slicers, including the TR550, TR350, and TR/BM350. These machines are designed to meet the demands of various food preparation environments, from small-scale operations to larger commercial kitchens, with features that enhance efficiency, precision, and ease of use.The Univex TR550 is recognized for its powerful and reliable performance. This model is equipped with a robust slice thickness adjustment, allowing users to achieve uniform cuts ranging from paper-thin to thicker slices. This versatility is especially beneficial when preparing meats, cheeses, and vegetables, enabling operators to handle a diverse range of recipes and presentation styles. It is also built with a heavy-duty construction that ensures longevity and reliability, even in high-volume settings.

Moving on to the TR350, this model combines compact design with powerful functionality. Its smaller footprint makes it ideal for establishments with limited space, such as cafes and small restaurants. Despite its size, the TR350 does not compromise on features, providing users with precise slicing capabilities and easy-to-use controls. The machine’s safety features—such as a blade guard and automatic shut-off—help ensure operator safety while maintaining efficiency.

The TR/BM350 is a variation that brings additional versatility to the table. Designed for operations that require both slicing and dicing functionality, this model is particularly beneficial for establishments preparing salads, sandwiches, or other mixed dishes. The TR/BM350 features quick-change slice and dice plates that allow for seamless transitions between tasks, promoting a productive workflow in busy kitchens.

All models in the Univex TR series incorporate advanced technologies, including high-performance slicing blades that guarantee clean cuts without damaging food product integrity. The easy-to-clean design ensures that hygiene standards are met, making these machines suitable for commercial food environments where cleanliness is crucial.

One notable characteristic of the TR series is its user-friendly interface. Operators can easily adjust settings and perform maintenance tasks without extensive training, making these machines accessible even for operators who are not highly experienced. With their combination of durability, flexibility, and safety features, the Univex TR550, TR350, and TR/BM350 slicers stand out as essential tools for food service professionals aiming to enhance their culinary offerings while optimizing kitchen efficiency.