INSTALLATION

Continued

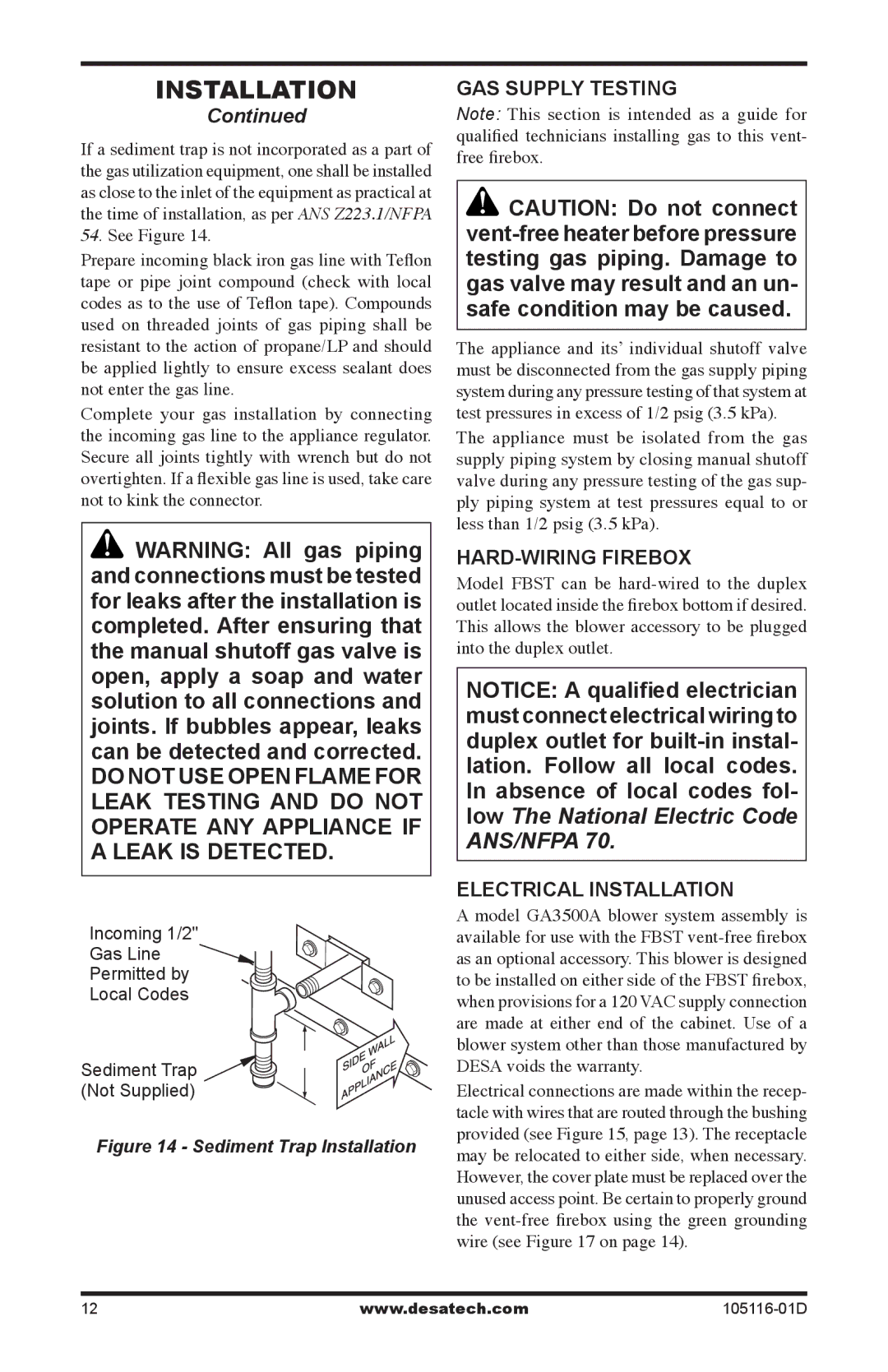

If a sediment trap is not incorporated as a part of the gas utilization equipment, one shall be installed as close to the inlet of the equipment as practical at the time of installation, as per ANS Z223.1/NFPA 54. See Figure 14.

Prepare incoming black iron gas line with Teflon tape or pipe joint compound (check with local codes as to the use of Teflon tape). Compounds used on threaded joints of gas piping shall be resistant to the action of propane/LP and should be applied lightly to ensure excess sealant does not enter the gas line.

Complete your gas installation by connecting the incoming gas line to the appliance regulator. Secure all joints tightly with wrench but do not overtighten. If a flexible gas line is used, take care not to kink the connector.

![]() WARNING: All gas piping and connections must be tested for leaks after the installation is completed. After ensuring that the manual shutoff gas valve is open, apply a soap and water solution to all connections and joints. If bubbles appear, leaks can be detected and corrected.

WARNING: All gas piping and connections must be tested for leaks after the installation is completed. After ensuring that the manual shutoff gas valve is open, apply a soap and water solution to all connections and joints. If bubbles appear, leaks can be detected and corrected.

DO NOT USE OPEN FLAME FOR LEAK TESTING AND DO NOT OPERATE ANY APPLIANCE IF A LEAK IS DETECTED.

Incoming 1/2"

Gas Line

Permitted by

Local Codes

Sediment Trap ![]()

![]()

(Not Supplied)

Figure 14 - Sediment Trap Installation

Gas supply testing

Note: This section is intended as a guide for qualified technicians installing gas to this vent- free firebox.

![]() CAUTION: Do not connect

CAUTION: Do not connect

The appliance and its’ individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing manual shutoff valve during any pressure testing of the gas sup- ply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa).

Hard-wiring Firebox

Model FBST can be

NOTICE: A qualified electrician must connect electrical wiring to duplex outlet for

Electrical Installation

A model GA3500A blower system assembly is available for use with the FBST

Electrical connections are made within the recep- tacle with wires that are routed through the bushing provided (see Figure 15, page 13). The receptacle may be relocated to either side, when necessary. However, the cover plate must be replaced over the unused access point. Be certain to properly ground the

12 | www.desatech.com |