Dutchwest

Use the Air Control Settings

that Work Best for You

No single combination of control settings will fit every situation. Each installation will differ depending on the quality of the fuel, the amount of heat desired, and how long you wish the fire to burn.

Control settings also depend on your particular instal- lation’s “draft,” or the force that moves air from the stove up through the chimney. Draft is affected by such things as the height, type, and location of the chimney, local geography, nearby obstructions, and other factors.

Too much draft may cause excessive temperatures in

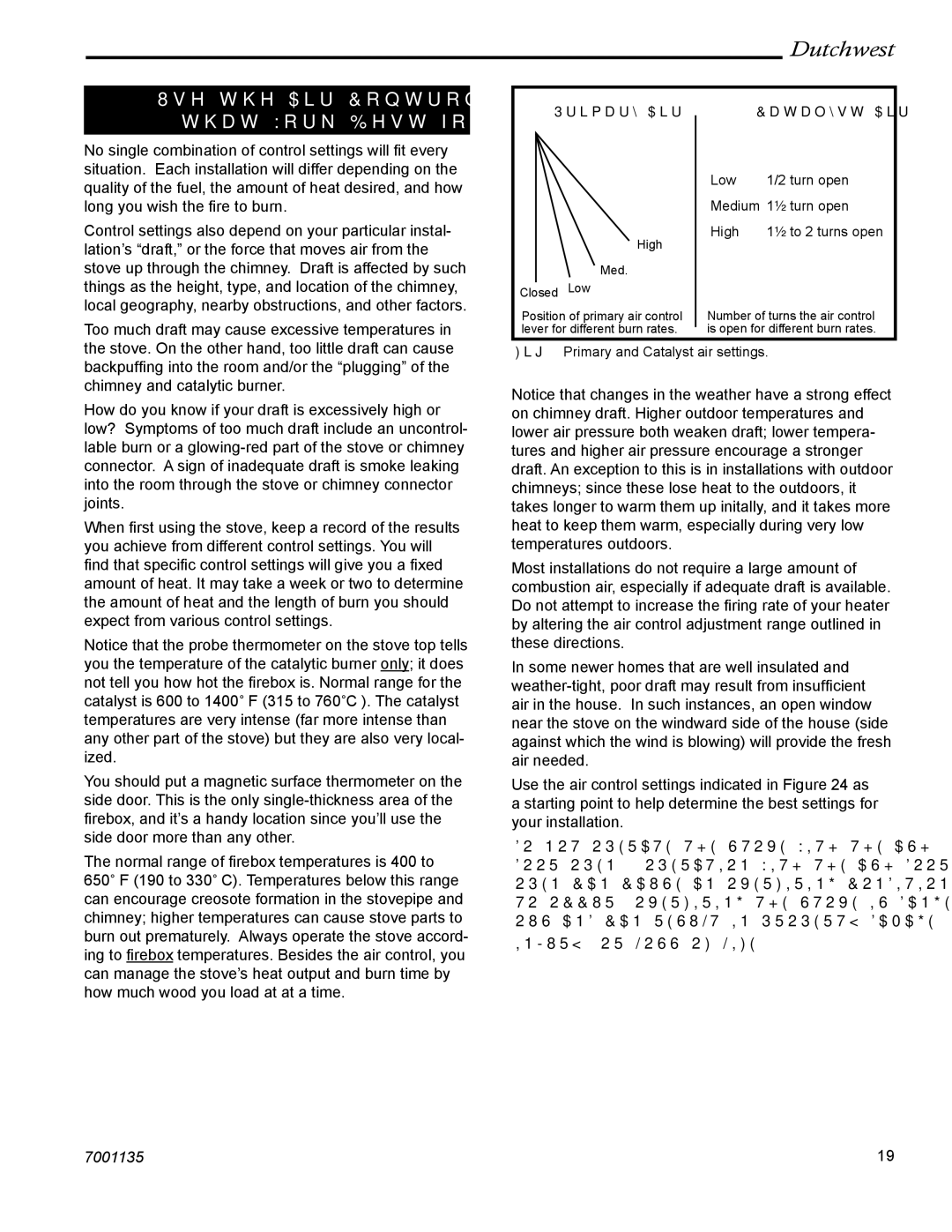

Primary Air

High

Med.

Closed Low

Position of primary air control lever for different burn rates.

Catalyst Air

Low | 1/2 turn open |

Medium | 1¹⁄₂ turn open |

High | 1¹⁄₂ to 2 turns open |

Number of turns the air control is open for different burn rates.

the stove. On the other hand, too little draft can cause backpuffing into the room and/or the “plugging” of the chimney and catalytic burner.

How do you know if your draft is excessively high or low? Symptoms of too much draft include an uncontrol- lable burn or a

When first using the stove, keep a record of the results you achieve from different control settings. You will find that specific control settings will give you a fixed amount of heat. It may take a week or two to determine the amount of heat and the length of burn you should expect from various control settings.

Notice that the probe thermometer on the stove top tells you the temperature of the catalytic burner only; it does not tell you how hot the firebox is. Normal range for the catalyst is 600 to 1400˚ F (315 to 760˚C ). The catalyst temperatures are very intense (far more intense than any other part of the stove) but they are also very local- ized.

You should put a magnetic surface thermometer on the side door. This is the only

The normal range of firebox temperatures is 400 to 650˚ F (190 to 330˚ C). Temperatures below this range can encourage creosote formation in the stovepipe and chimney; higher temperatures can cause stove parts to burn out prematurely. Always operate the stove accord- ing to firebox temperatures. Besides the air control, you can manage the stove’s heat output and burn time by how much wood you load at at a time.

Fig. 25 Primary and Catalyst air settings.

Notice that changes in the weather have a strong effect on chimney draft. Higher outdoor temperatures and lower air pressure both weaken draft; lower tempera- tures and higher air pressure encourage a stronger draft. An exception to this is in installations with outdoor chimneys; since these lose heat to the outdoors, it takes longer to warm them up initally, and it takes more heat to keep them warm, especially during very low temperatures outdoors.

Most installations do not require a large amount of combustion air, especially if adequate draft is available. Do not attempt to increase the firing rate of your heater by altering the air control adjustment range outlined in these directions.

In some newer homes that are well insulated and

Use the air control settings indicated in Figure 24 as a starting point to help determine the best settings for your installation.

DO NOT OPERATE THE STOVE WITH THE ASH DOOR OPEN. OPERATION WITH THE ASH DOOR OPEN CAN CAUSE AN OVERFIRING CONDITION TO OCCUR. OVERFIRING THE STOVE IS DANGER- OUS AND CAN RESULT IN PROPERTY DAMAGE,

INJURY, OR LOSS OF LIFE.

7001135 | 19 |