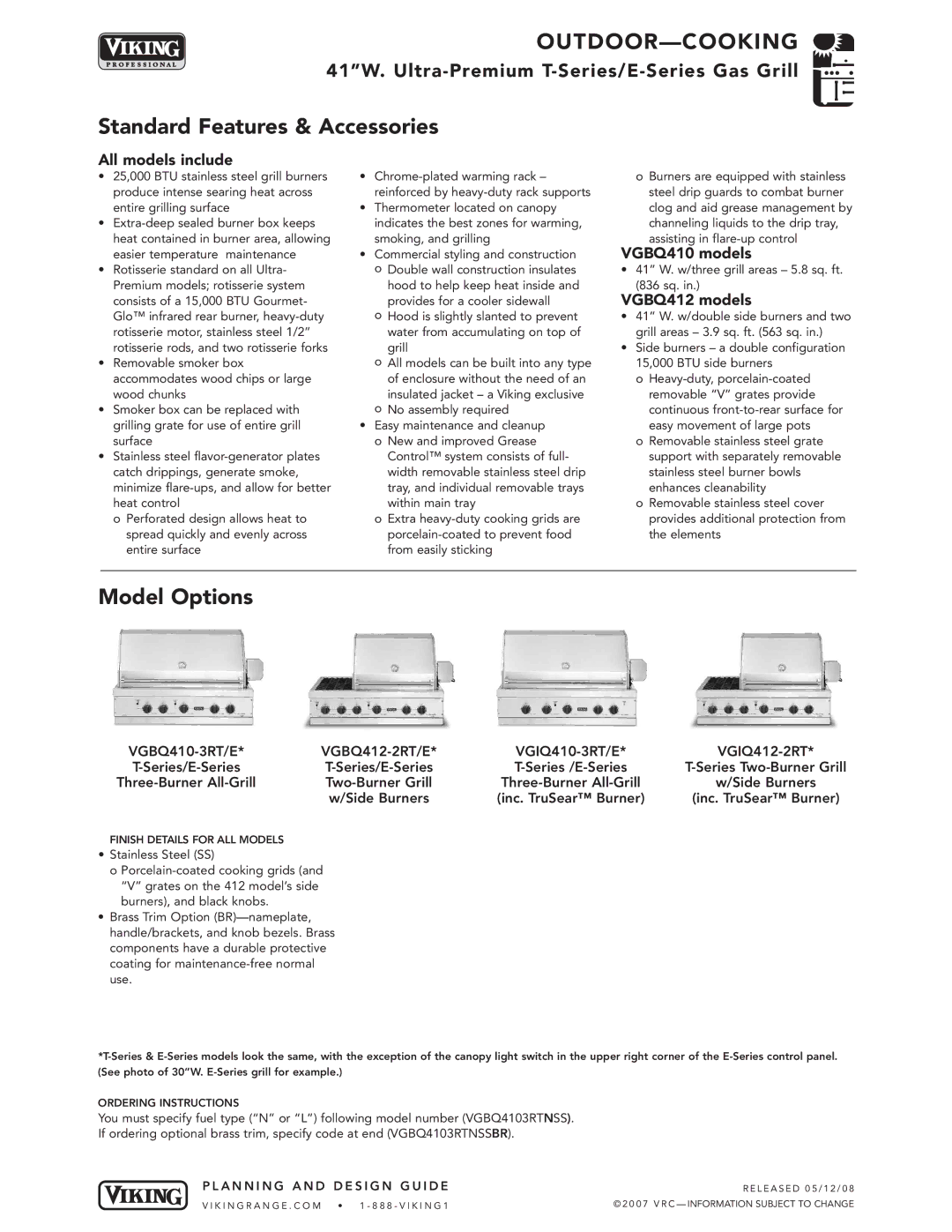

VGIQ410-3RT/E*, VGIQ412-2RT*, VGBQ412-2RT/E*, VGBQ410-3RT/E* specifications

The Viking range of industrial valves includes models such as the VGBQ410-3RT/E*, VGBQ412-2RT/E*, VGIQ412-2RT*, and VGIQ410-3RT/E*. These valves are known for their robust design and reliability, making them ideal for a variety of demanding applications in sectors such as HVAC, automotive, and process industries.One of the standout features of the Viking VGBQ models is their ability to efficiently handle both hot and cold water systems. The valves are designed with precision-engineered components that ensure a tight seal, preventing leaks while maintaining optimal flow rates. This characteristic is crucial in industrial settings where even minor leaks can lead to significant operational inefficiencies and increased costs.

The VGIQ series, on the other hand, incorporates advanced technologies into its design. These valves are equipped with integrated actuators that provide precise control over fluid flow. The electronic controls allow for automated operation, which enhances the efficiency of the systems in which these valves are installed. The actuators are designed to be responsive and can accommodate variable flow rates, making them highly adaptable to changing operational conditions.

All models feature durable construction materials, including corrosion-resistant alloys that ensure longevity even in harsh environments. This durability reduces the need for frequent maintenance and replacements, providing long-term cost savings for users. Additionally, the Viking valves are designed for easy installation, which minimizes downtime during setup and reduces overall labor costs.

In terms of safety, these valves come with built-in mechanisms that provide fail-safe operations. In the event of a power failure or other malfunctions, the valves automatically revert to a preset position, preventing uncontrolled flow that could compromise system integrity.

Another significant characteristic of these Viking valves is their versatility. They can be employed in a range of applications, from managing water supply systems to playing critical roles in heating and cooling processes. Their compatibility with various control systems further enhances their usability across different platforms.

Overall, the Viking VGBQ410-3RT/E*, VGBQ412-2RT/E*, VGIQ412-2RT*, and VGIQ410-3RT/E* valves represent an excellent combination of efficiency, durability, and technology. With their advanced features and robust design, they are well-suited for modern industrial applications, ensuring reliable performance and operational efficiency.