VMOC205SS, DMOC205SS specifications

The Viking DMOC205SS and VMOC205SS are two state-of-the-art microwave ovens that redefine cooking convenience and efficiency. Designed for modern kitchens, these appliances come equipped with a range of features and technologies that enhance their usability and performance.One of the most notable aspects of the Viking DMOC205SS and VMOC205SS is their powerful cooking capabilities. Both models utilize an advanced cooking system that ensures even heat distribution, resulting in perfectly cooked meals every time. With a robust wattage of up to 1,200 watts, these microwaves can quickly and efficiently prepare a wide variety of dishes.

The DMOC205SS features a spacious interior, offering 2.1 cubic feet of cooking space, making it ideal for larger families or those who frequently entertain guests. The VMOC205SS variant also shares a similar capacity but comes with additional features tailored for versatility. The interior design of both models includes a stainless steel finish that not only enhances durability but also adds a touch of elegance to any kitchen.

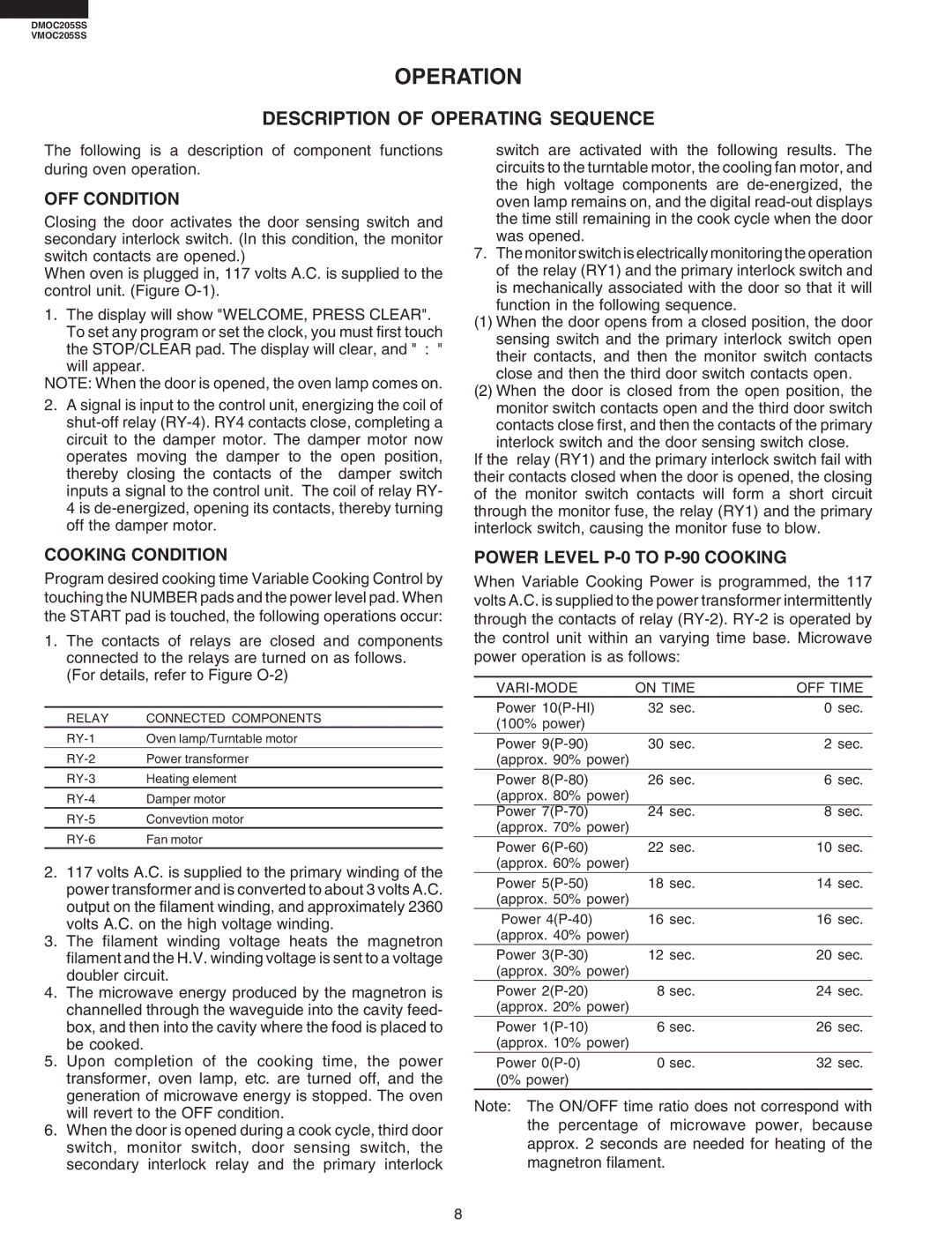

Functionality is at the forefront of the Viking DMOC205SS and VMOC205SS. Both models are equipped with multiple cooking modes, including microwave, convection, and grilling options. This multi-functional capability allows users to seamlessly switch between cooking methods, ensuring optimal results for various recipes. The intuitive control panel features easy-to-read buttons and a digital display, making it user-friendly for all cooking levels.

In terms of technology, these Viking microwaves incorporate sensor cooking, which automatically detects the moisture and temperature of food, adjusting cooking times accordingly. This feature not only prevents overcooking but also ensures consistently delicious results. The models also come with pre-programmed cooking settings for popular dishes, making meal preparation simpler and quicker.

Energy efficiency is another critical aspect of the Viking DMOC205SS and VMOC205SS. Both models are designed to minimize energy consumption while maximizing performance, which is beneficial for both the environment and the homeowner’s energy bills.

Safety features are embedded within the design of these microwaves. They include a child lock function to prevent accidental use, as well as a timer that ensures food is cooked for the precise amount of time needed.

In summary, the Viking DMOC205SS and VMOC205SS are exceptional microwave ovens that combine advanced technology, practical features, and stylish design. Their powerful cooking capabilities, user-friendly controls, and energy-efficient operation make them a perfect addition to any modern kitchen. These appliances empower users to explore a wide range of cooking possibilities, bringing convenience and quality to meal preparation.