•Supply and return air flow from the evaporator unit shall be unobstructed for at least 1 foot.

•There is a gravity drain line so that it can not be installed above the evaporator unit. Otherwise a condensation pump must be used.

3. Air Sensor

•The air sensor can be located in the wine room or the return air area, but not the supply air area.

4. Refrigeration Piping and Charging

NOTES: ALWAYS USE THE SUPERHEAT AND SUBCOOLING, PRESSURE READINGS TO CHARGE REFRIGERANT PROPERLY, THE LISTED CHARGES ARE FOR REFERENCE ONLY.

•The installation order starts from condensing unit (including the receiver), liquid line

•The subcooling at the condensing unit shall be around 10°F. The charge may be complete when there are no more bubbles forming in the sight glass.

•The evaporator’s constant pressure expansion valve is set around 38- 40°F at factory. This pressure setting gives a dew point to maintain the humidity for storing wine.

•The superheat at the evaporator unit shall be around

•Low side pressure: 33 psig

•High side pressure: 130

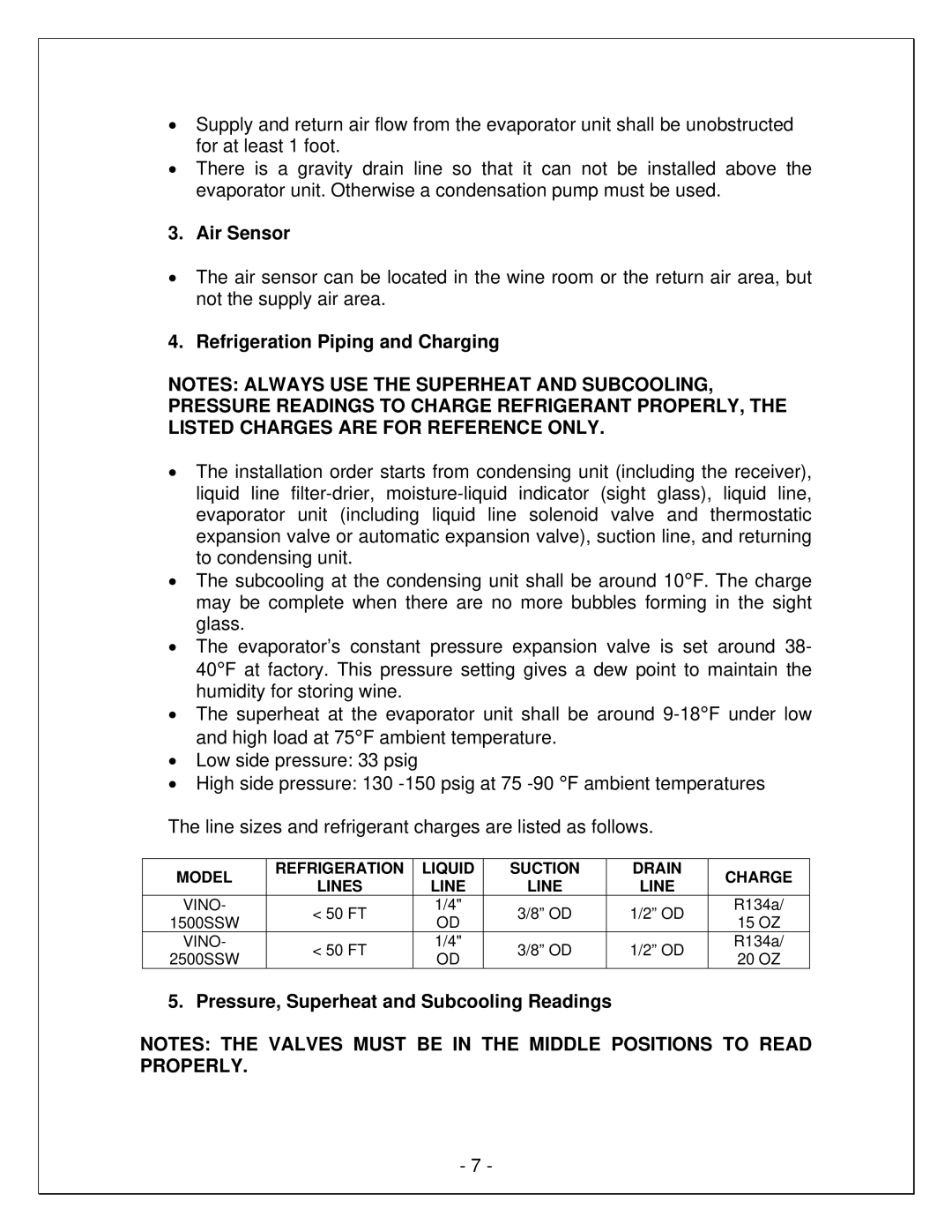

The line sizes and refrigerant charges are listed as follows.

MODEL | REFRIGERATION | LIQUID | SUCTION | |

LINES | LINE | LINE | ||

| ||||

VINO- | < 50 FT | 1/4" | 3/8” OD | |

1500SSW | OD | |||

|

| |||

VINO- | < 50 FT | 1/4" | 3/8” OD | |

2500SSW | OD | |||

|

|

DRAIN

LINE

1/2” OD

1/2” OD

CHARGE

R134a/

15OZ R134a/

20OZ

5. Pressure, Superheat and Subcooling Readings

NOTES: THE VALVES MUST BE IN THE MIDDLE POSITIONS TO READ PROPERLY.

- 7 -