How steam becomes PowerSteam.

PowerSteam combines heat and speed to produce a more powerful cooking steam. The steam gets its extra “power” through a unique

Superheated steam increases cooking energy by 10%.

Steam at sea level is hot. But superheated steam is hotter. Before steam reaches the cooking compartment, it’s reheated with either fl ue gas or a secondary electric heater. Here the steam temperature rises from its normal sea level temperature of 212°F to its PowerSteam temperature of 235°F. By raising the steam temperature, the cooking energy is increased by at least 10%. Vulcan is the fi rst company to use superheated steam for steam cooking. The process is patent pending.

Staged fi lling keeps the boil boiling.

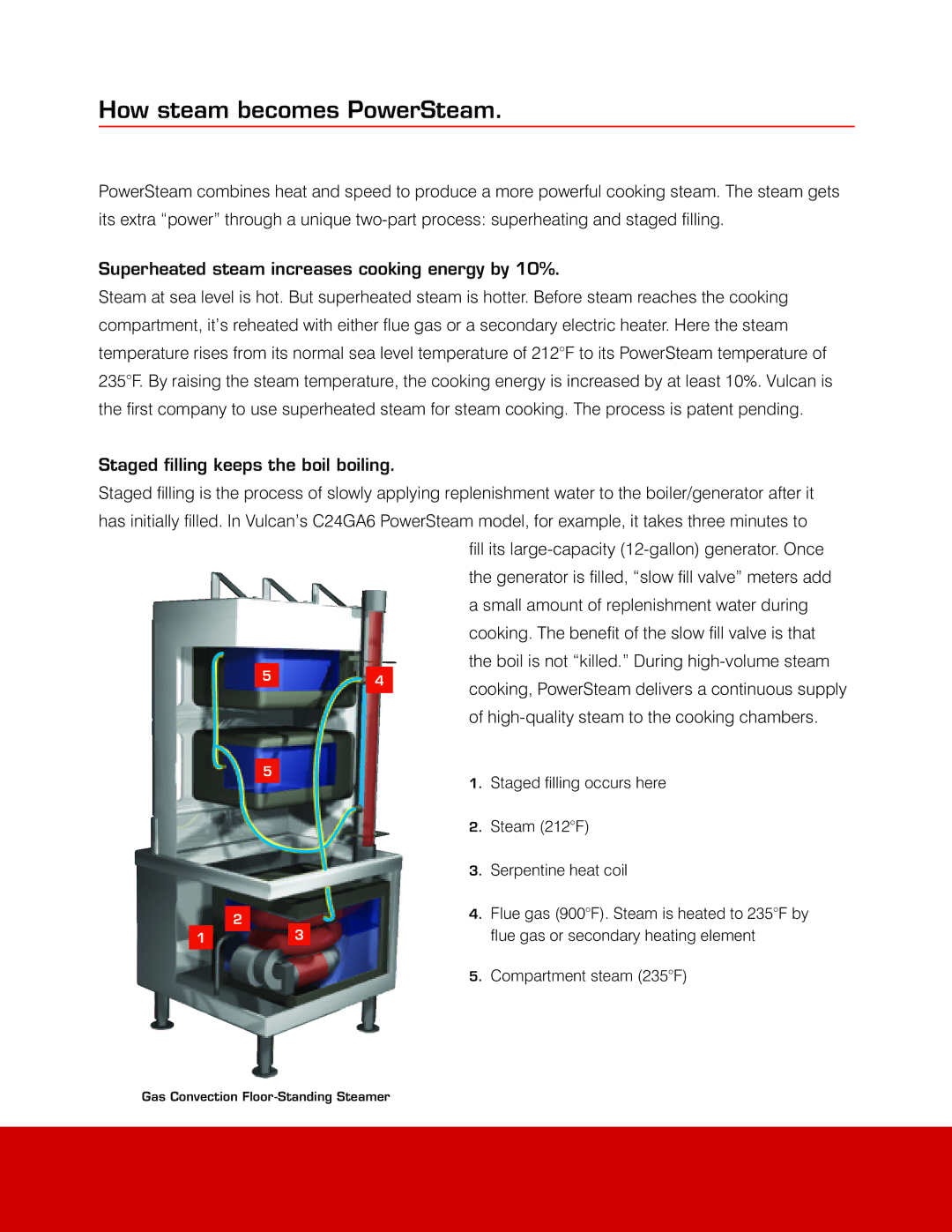

Staged fi lling is the process of slowly applying replenishment water to the boiler/generator after it has initially fi lled. In Vulcan’s C24GA6 PowerSteam model, for example, it takes three minutes to

fi ll its

5 | 4 | cooking, PowerSteam delivers a continuous supply |

| ||

|

| |

|

| of |

5

2

13

1.Staged fi lling occurs here

2.Steam (212°F)

3.Serpentine heat coil

4.Flue gas (900°F). Steam is heated to 235°F by fl ue gas or secondary heating element

5.Compartment steam (235°F)

Gas Convection