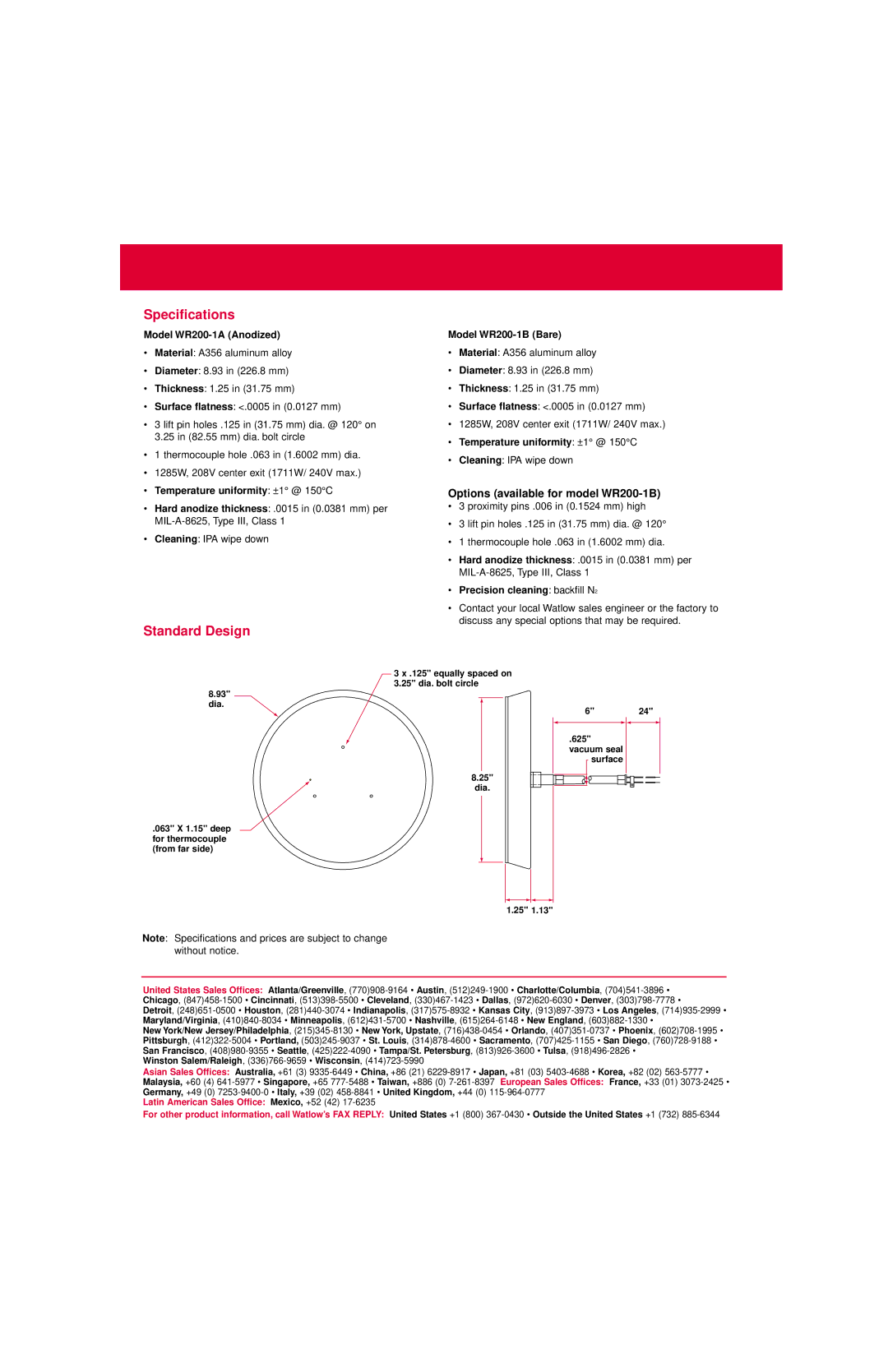

WR200-1B, WR200-1A specifications

The Watlow Electric WR200 series, including models WR200-1A and WR200-1B, represents a pivotal advancement in heating technology for industrial applications. These robust and reliable temperature controllers are engineered to enhance efficiency, precision, and ease of use in various heating processes.One of the standout features of the WR200 series is its advanced microprocessor-based control technology. This innovative design enables precise temperature regulation, ensuring that processes remain stable under varying environmental conditions. Users benefit from an extensive temperature range, making these controllers suitable for numerous applications, from laboratory experiments to industrial manufacturing.

Both WR200-1A and WR200-1B models exhibit user-friendly interfaces, with intuitive controls that simplify the configuration process. The large digital display allows for easy monitoring of temperature readings and settings, ensuring that operators can make necessary adjustments quickly. This feature is particularly beneficial in fast-paced environments where time is of the essence.

Moreover, the WR200 series is equipped with advanced diagnostic capabilities. These systems can provide real-time feedback on performance metrics, alerting users to potential issues before they escalate into more significant problems. This predictive maintenance approach not only enhances safety but also reduces downtime, ultimately contributing to improved operational efficiency.

Durability is another hallmark of the WR200 series. Constructed with high-quality materials, these controllers are designed to withstand harsh industrial environments. They offer resistance to moisture, dust, and contaminants, which is crucial for maintaining reliable performance in demanding applications.

Additionally, the WR200-1A and WR200-1B support a variety of communication protocols. This feature allows for seamless integration into existing control systems, making it easier for businesses to adopt this technology without overhauling their entire infrastructure. The versatility in connectivity options, including digital inputs and outputs, empowers users to customize the functionality of their controllers according to their specific needs.

In summary, the Watlow Electric WR200-1A and WR200-1B models exemplify cutting-edge technology in temperature control. With features such as advanced microprocessor control, user-friendly interfaces, diagnostic capabilities, and durable construction, these controllers are an excellent choice for industries seeking reliable and efficient heating solutions. Whether in a lab setting or on the factory floor, the WR200 series is engineered to deliver optimal performance and enhance productivity across a wide range of applications.