|

|

|

| Model EFL33 | |

General Safety Information |

| a 45º angle with the valve pivot on | 7. When a tether switch is used, rigid | ||

(Continued) |

| top. In a vertical position, solids will | discharge pipe is required. If the | ||

The pump motor |

| tend to lodge on the valve flapper | pump is allowed to move, the | ||

| and can prevent it from opening. | tether switch could be restricted | |||

is equipped with |

| ||||

|

|

| by the basin wall, preventing the | ||

automatic resetting thermal protector | 3. | Drill a 1/8 inch hole in the discharge | |||

and may restart unexpectedly. Protector |

| pipe approximately 1 inch to 2 inch | pump from operating. | ||

tripping is an indication of motor |

|

| |||

| above the pump discharge when | Before removing | |||

overloading as a result of operating |

| ||||

| a check valve is used. The hole | pump from basin | |||

the pump at low heads (low discharge |

| ||||

restriction), excessively high or low |

| prevents air locking of the pump at | for service, always disconnect electrical | ||

voltage, inadequate wiring, incorrect |

| the initial | power to pump and control switch. For | ||

motor conditions, or a defective motor |

| lose prime. |

| any work on pump or switch, always | |

or pump. |

|

| unplug the power cord. Do not just turn | ||

4. | A gate valve should be installed in | ||||

14. IThis pump is designed to transfer | off circuit breaker or unscrew fuse. | ||||

| the system after the check valve. This |

| |||

water in cycles. Using this pump in |

|

| |||

| gate valve should be a full port valve | Maintenance | |||

a continuous duty application by |

| ||||

| which will pass 3/4 inch solids or as | Make certain that | |||

manipulating the switch to stay on, |

| ||||

| required by state and local codes. | ||||

will affect the performance and the |

| the pump is | |||

| This gate valve permits removal of | unplugged before attempting to service | |||

life of the product. |

| ||||

| the pump and/or check valve for | or remove any component. This pump is | |||

15. Protect electrical cord from sharp |

| ||||

| servicing. |

| assembled in the factory using special | ||

objects, hot surfaces, oil, and | 5. A union should be installed between | equipment; therefore only authorized | |||

chemicals. Avoid kinking the cord. | service dealers or qualified electricians | ||||

| the check valve and the pump so the | ||||

Replace or repair damaged or worn |

| should attempt to repair this unit. | |||

| pump can be removed with least | ||||

cords immediately. Use wire of |

| Improper repair can cause an electrical | |||

| disturbance of the piping. |

| |||

adequate size to minimize voltage |

|

| shock hazard. | ||

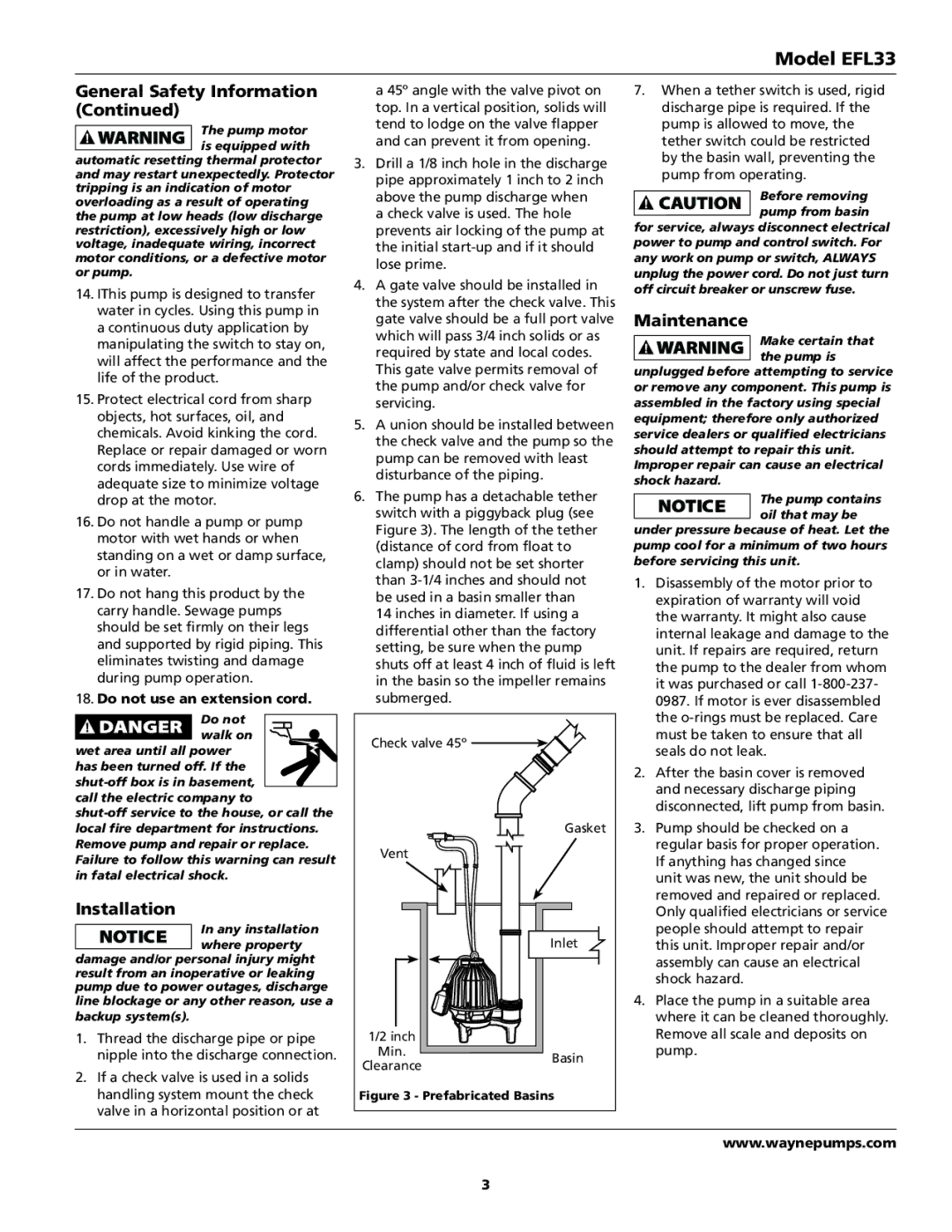

6. The pump has a detachable tether | |||||

drop at the motor. | The pump contains | ||||

16. Do not handle a pump or pump |

| switch with a piggyback plug (see | oil that may be | ||

| Figure 3). The length of the tether | under pressure because of heat. Let the | |||

motor with wet hands or when |

| ||||

| (distance of cord from float to | pump cool for a minimum of two hours | |||

standing on a wet or damp surface, |

| ||||

| clamp) should not be set shorter | before servicing this unit. | |||

or in water. |

| ||||

| than | 1. Disassembly of the motor prior to | |||

17. Do not hang this product by the |

| ||||

| be used in a basin smaller than | expiration of warranty will void | |||

carry handle. Sewage pumps |

| 14 inches in diameter. If using a | the warranty. It might also cause | ||

should be set firmly on their legs |

| differential other than the factory | internal leakage and damage to the | ||

and supported by rigid piping. This |

| setting, be sure when the pump | unit. If repairs are required, return | ||

eliminates twisting and damage |

| shuts off at least 4 inch of fluid is left | the pump to the dealer from whom | ||

during pump operation. |

| in the basin so the impeller remains | it was purchased or call | ||

18. Do not use an extension cord. |

| submerged. |

| 0987. If motor is ever disassembled | |

Do not |

|

|

| the | |

walk on |

| Check valve 45º |

| must be taken to ensure that all | |

wet area until all power |

|

| seals do not leak. | ||

|

|

| |||

has been turned off. If the |

|

|

| 2. After the basin cover is removed | |

|

|

| |||

|

|

| and necessary discharge piping | ||

call the electric company to |

|

|

| ||

|

|

| disconnected, lift pump from basin. | ||

|

|

| |||

|

|

| 3. Pump should be checked on a | ||

local fire department for instructions. |

|

| Gasket | ||

Remove pump and repair or replace. |

| Vent |

| regular basis for proper operation. | |

Failure to follow this warning can result |

|

| If anything has changed since | ||

|

|

| |||

in fatal electrical shock. |

|

|

| unit was new, the unit should be | |

Installation |

|

|

| removed and repaired or replaced. | |

|

|

| Only qualified electricians or service | ||

In any installation |

|

| Inlet | people should attempt to repair | |

where property |

|

| this unit. Improper repair and/or | ||

damage and/or personal injury might |

|

|

| assembly can cause an electrical | |

result from an inoperative or leaking |

|

|

| shock hazard. | |

pump due to power outages, discharge |

|

|

| ||

|

|

| 4. Place the pump in a suitable area | ||

line blockage or any other reason, use a |

|

|

| ||

backup system(s). |

|

|

| where it can be cleaned thoroughly. | |

1. Thread the discharge pipe or pipe |

| 1/2 inch |

| Remove all scale and deposits on | |

nipple into the discharge connection. |

| Min. | Basin | pump. | |

Clearance |

| ||||

2. If a check valve is used in a solids |

|

| |||

|

|

|

| ||

handling system mount the check | Figure 3 - Prefabricated Basins |

| |||

valve in a horizontal position or at |

|

|

|

| |

|

|

|

| www.waynepumps.com | |

|

| 3 |

|

| |