ESP45 specifications

The Wayne ESP45 is a standout model in the world of submersible sump pumps, renowned for its efficiency, durability, and innovative technology. This pump is designed for residential and commercial applications, providing reliable protection against water damage caused by flooding or excess groundwater.One of the key features of the Wayne ESP45 is its powerful motor. Equipped with a 1/2 HP motor, it is capable of displacing up to 4,600 gallons of water per hour. This makes it suitable for handling heavy inflows during significant rain events or for managing water pooling in basements. The motor is also thermally protected, ensuring it doesn’t overheat during prolonged use, thereby enhancing its longevity.

The ESP45 employs a superior engineering design that includes a durable thermoplastic construction. This material protects the pump from corrosion and wear, ideally suited for dealing with harsh conditions typically found in sump applications. The pump is designed for consistent performance and operates quietly, minimizing disturbances in your living space.

One of the standout technologies in the Wayne ESP45 is its vertical float switch, which provides automatic operation. This feature allows the pump to turn on and off based on water levels, ensuring that your sump area is always protected without the need for manual intervention. The float switch is built to withstand wear and tear, allowing for reliable operation over time.

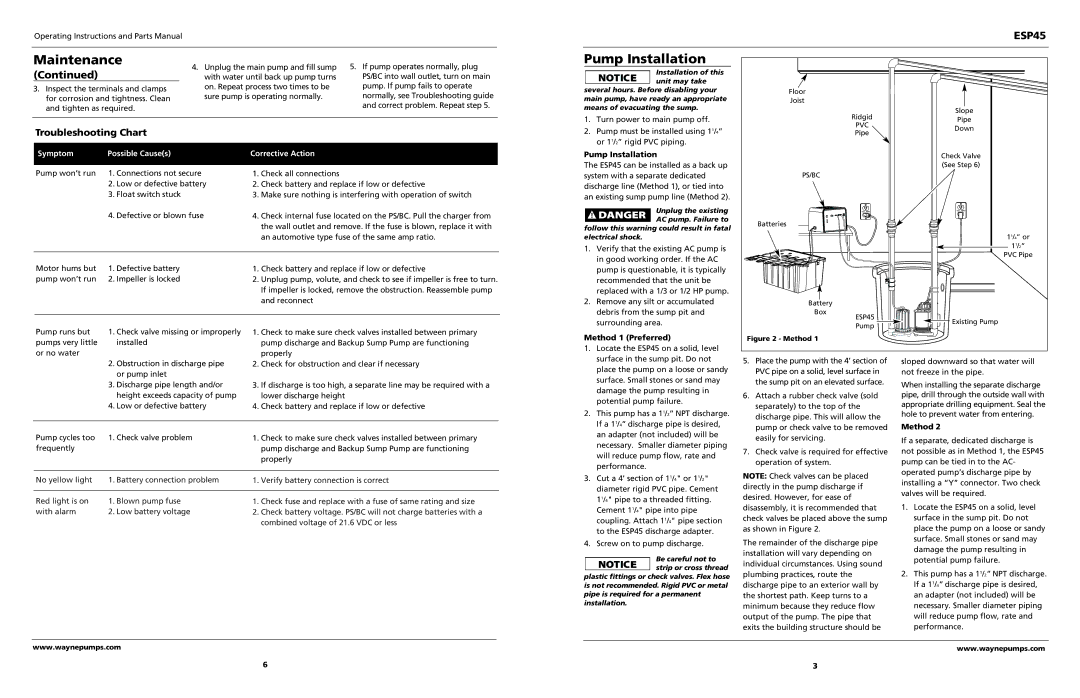

Another characteristic that sets the Wayne ESP45 apart is its ease of installation. The pump comes with a simple setup process, featuring a standard 1-1/2 inch NPT discharge that easily connects to existing plumbing systems. This allows homeowners and contractors to install the pump quickly, making it an ideal choice for those looking to enhance their water management solutions efficiently.

Moreover, the Wayne ESP45 is compatible with various backup systems, offering peace of mind by ensuring that it remains operational during power outages. This versatility increases its reliability, making it a go-to option for anyone looking to safeguard their property from water damage.

In summary, the Wayne ESP45 combines powerful performance, durable construction, and innovative technology, making it one of the most reliable submersible sump pumps available. With its efficient motor, advanced automatic operation, and simple installation process, it serves as an essential tool for protecting homes from flooding and water damage.