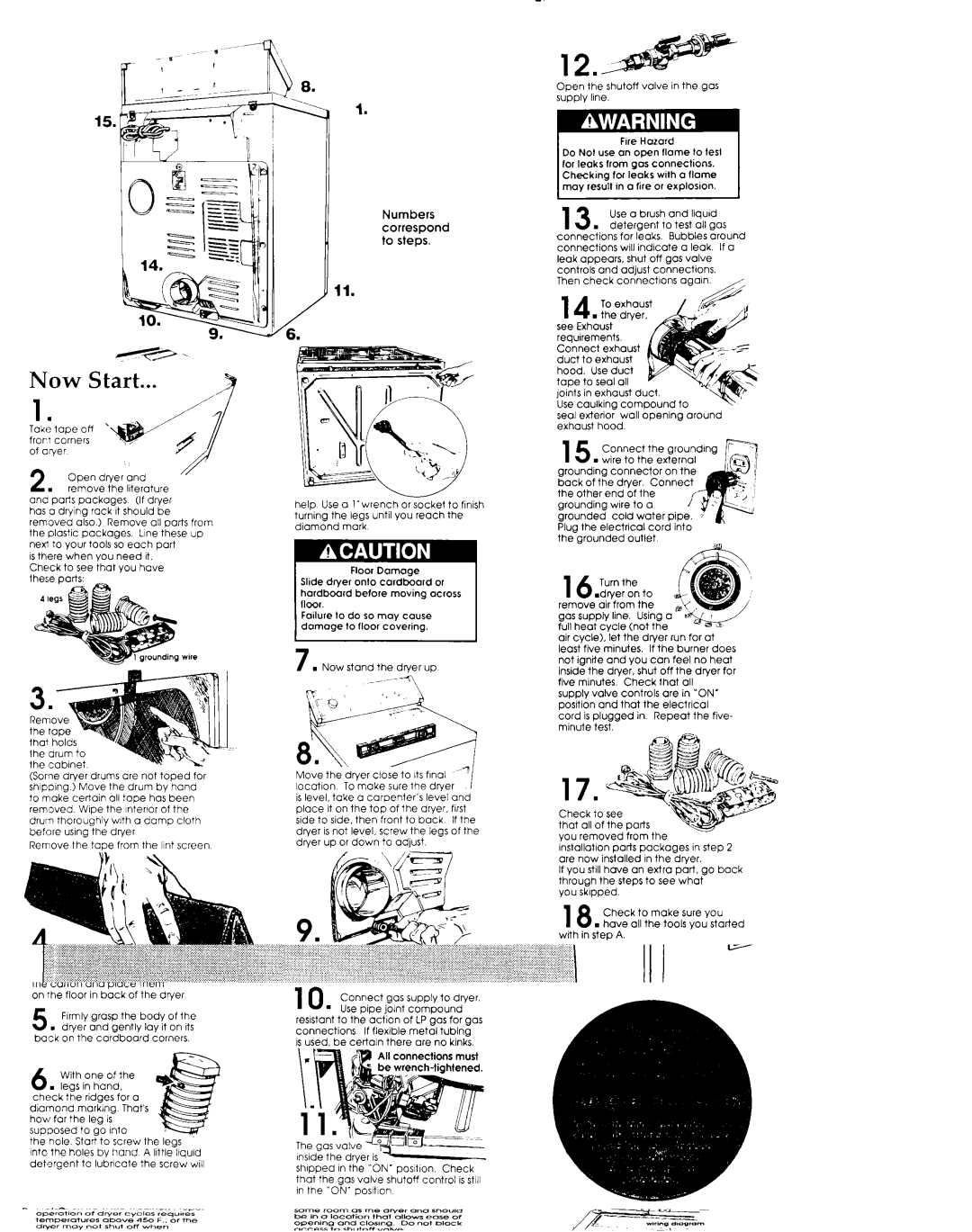

Now Start...

1

Tokitapeoff fr0rt corners of oryer

2 Open dryer and

. remove the literature and parts packages (If dryer has o drying rack rt should be removed also.) Remove all parts from the plastic packages. Line these up next to your tools so each part

is there when you need it. Check to see that YOU have

ihe drum to the cabinet

(Some dryer drums ore not toped for shIpping 1 Move the drum by hand to make certain all tape has been removed Wipe the lnterlor of the drum thoroughly v&h CIdamp cloth before usrng the dryer

Remove the tape from the IInt screen

Take two of the cardboard corners from the carton and place them

on the floor in bbck of the dryer

5 Firmly grasp the body of the n dryer ond gently lay it on Its

back on the cardboard corners.

6 With one of the

. legs in hand, check the ridges for o diamond marklng That’s how for the leg is supoosed to ao Into

the hole. Stortlto screw the legs into the holes by hand A little ltqurd detergent to lubrlcale the screw ~111

Panel C

Numbers correspond to steps.

11.

help Use a l’wrench or socket to finish turning the legs until you reach the diamond mark

7. Now stand the dryer up __

Move the dryer close to its final ‘a

locotron To make sure the drver i is level, take o carpenter’s level and place it on the top of the dryer, first side to side, then front to back If the drver is not level. screw the leas of the dr+er up or down to adjust. -

9 .

Remove the red cop from the the gas pipe. Move the dryer into Its final position.

10 Connect gas supply to dryer.

. Use pipe joint compound

resrstant to the action of LP gas for gas connections If flexible metal tubina is used. be certoln there crre no kinks

Inside the dryer is’4-

shopped In the “ON’ posItron. Check that the gas valve shutoff control is still in the “ON’ posItIon

Open the shutoff valve in the gas supply line.

Frre Hazard

Do Not use on open flame lo IeSl for leaks from gas connections. Checking for leaks wrth a flame may result in 0 fire or explosion.

13 Use CIbrush and liqurd

. detergent to test all gas connections for leaks. Bubbles around connections will indrcate a leak. If a leak appears, shut off gas valve controls and adjust connections.

Then check connecttons ogorn A,

14 To exhaust

. the dryer.

see Exhaust requirements. Connect exhaust

duct to exhaust &, hood. Use duct tape to seal all joi&s in exhaust duct.

Use caulking compound to Y seal exterior wall opening around exhaust hood

15 Connect the grounding n wire to the external

grounding connector on the back of the dryer. Connect the other end of the grounding wtre to o grounded cold water pipe. Plug the electrtcal cord into

16 Turn the

.dryer on to remove air from the gas supply line. Using 0 full heat cycle (not the

air cycle). let the dryer run for at least five minutes. If the burner does not ignite and you can feel no heat inside the dryer. shut off the dryer for five minutes. Check that all

supply valve controls ore in “ON’ position and that the electrical

cord is plugged in. Repeat the five- minute test.

17.

Check to see

that all of the parts you removed from the

installatron parts packages in step 2 are now installed rn the dryer.

If you still have an extra part. go back through the steps to see what

you skipped.

18 Check to make sure you

. have all the tools YOU started wdh in step A.