Before you start...

Mark an X across the letter or number as you complete each step

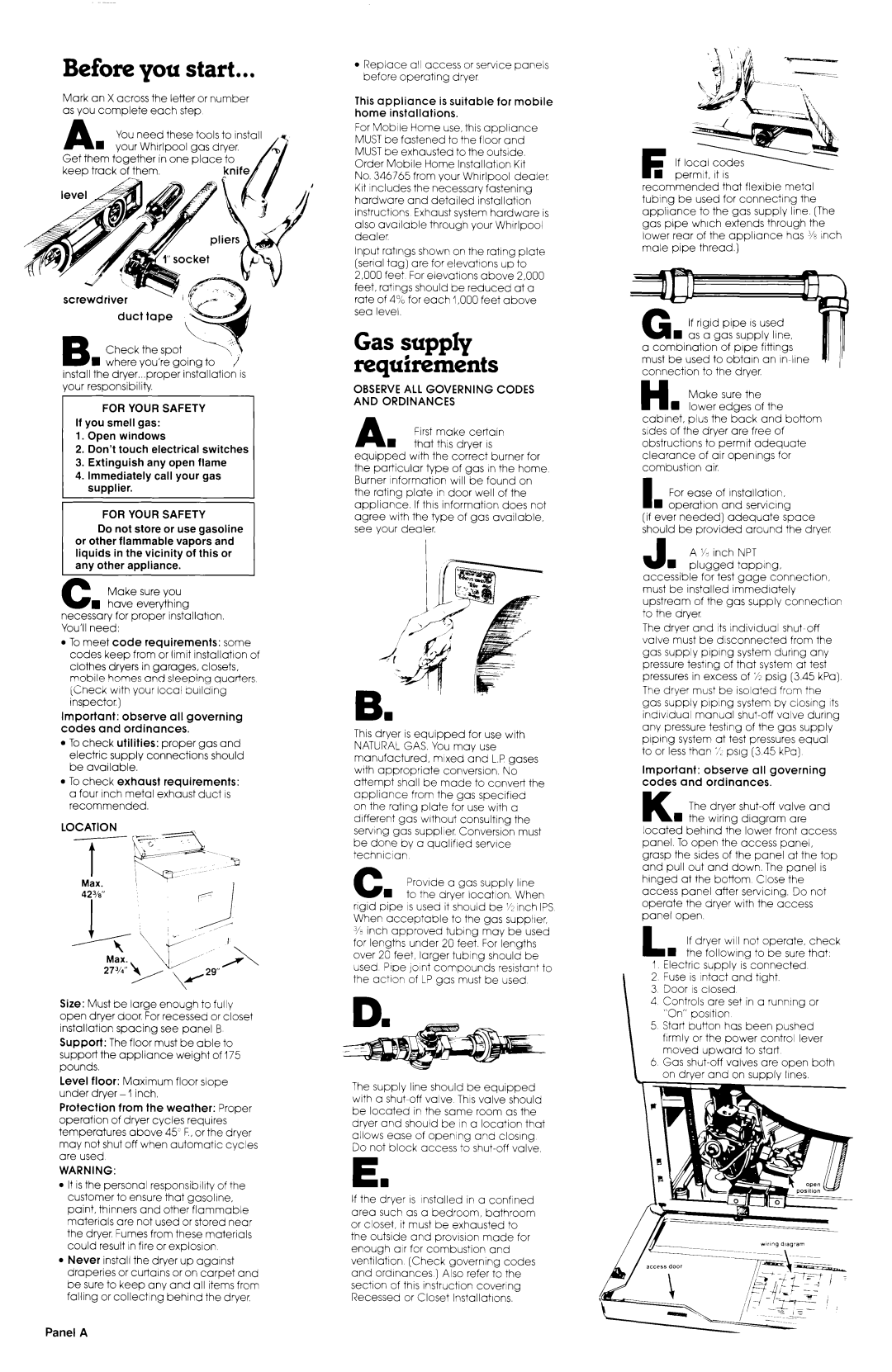

You need these tools to i

screwdriver

install the dryer...proper installation is Your responsibility

FOR YOUR SAFETY

If you smell gas:

1.Open windows

2.Don’t touch electrical switches

3.Extinguish any open flame

4.Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

Cn | Make | sure you |

|

have | everything |

| |

necessary | for proper instillation. |

| |

You’ll need: |

|

| |

l To meet | code | requirements: | some |

codes keep from or limit installation of clothes dryers in garages, closets, mobile homes and sleeping quarters [Check with your local Dullding inspector.)

Important: observe all governing codes and ordinances.

l To check utilities: proper gas and electric supply connections should be available.

l To check exhaust requirements: a four inch metal exhaust duct IS recommended.

LOCATION

b

Max. / 423/a”

Size: Must be large enough to fully open dryer door. For recessed or closet installation spacing see panel B

Support: The floor must be able to suppod the appliance weight of 175 pounds.

Level floor: Maximum floor slope under dryer - 1 inch,

Protection from the weather: Proper operation of dryer cycles requires temperatures above 45’ F.,or the dryer may not shut off when automatic cycles ore used

WARNING:

lIt is the personal responsibility of the customer to ensure that gasoline, paint, thinners and other flammable materials are not used or stored near the dryer. Fumes from these materials could result In fire or explosion

l Never install the dryer up against draperies or curtains or on carpet and be sure to keep any and all items from falling or collecting behind the dryer,

. Replace all access or sewice panels before operating dryer

This appliance is suitable for mobile home installations.

For Mobile Home use, this appliance MUST be fastened to the floor and MUST be exhausted to the outside. Order Mobile Home Installation Kit No. 346765 from your WhIrlpool dealer. Kit includes the necessary fastening hardware and detailed installation instructions Exhaust system hardware is also avallable through your WhIrlpool dealer.

Input ratings shown on the rating plate (senal tag) are for elevattons up to

2,000 feet For elevations above 2,000 feet, ratings should be reduced at a rate of 4% for each 1,000 feet above sea level.

Gas supply requirements

OBSERVE ALL GOVERNING CODES AND ORDINANCES

A n | First make certain | |||

that | this | dryer | IS | |

equipped | with | the | corkect | burner for |

the particular type of gas in the home. Burner information will be found on the rating plate in door well of the appliance. If this information does not agree with the type of gas available, see your dealer,

This dryer is equipped for use with NATURAL GAS. You may use manufactured, mixed and L.P gases with appropriate conversion. No attempt shall be made to convert the appliance from the gas specified

on the rating plate for use with a different gas wlthout consulting the serving gas supplier. Conversion must be done by a qualified service technician

C Provide a gas supply line n to the dryer location. When

rlgid pipe IS used it’should be % inch IPS When acceptable to the gas supplier, s/s inch approved tubing may be used for lengths under 20 feet. For lengths over 20 feet, larger tubing should be used Pipe joint compounds resistant to the action of LP gas must be used

The supply line should be equipped with a

E.

If the dryer is installed in a confined area such as a bedroom, bathroom or closet, it must be exhausted to the outside and provlsion made for enough air for combustion and ventilation (Check governing codes and ordinances ) Also refer to the section of this instruction covering Recessed or Closet Installations.

If I

permit, it Is recommended that flexible metal tubing be used for connecting the appliance to the gas supply line. (The gas pipe which extends through the lower rear of the appliance has yg Inch male pipe thread.)

If rigid pipe ISused H as a gas supply line,

a combinationof pip& fittings must be used to obtain an

H Make sure the

n lower edaes of the cabinet, plus the bvack and bottom sides of the dryer are free of obstructions to permit adequate clearance of air openings for combustion air

I For ease of Installation, H operation and servicing

(if ever needed] adequate space should be provided around the dryer

J A ‘/1inch NPT n plugged tapplng,

accessible for test gage connection, must be installed immediately upstream of the gas supply connectlon io the dryer.

The dryer and its lndivldual

to or less ihan ;‘, pslg (3.45 kPa)

Important: observe all governing codes and ordinances.

K The dryer

located behlnd the low’er front access panel. To open the access panel, grasp the sides of the panel at the top and pull out and down. The panel is hinged at the bottom Close the access panel after sewicing. Do not operate the dryer with the access panel open.

L If dryer will not operate, check n the followlna to be sure that:

I. Electric supply iiconnected 2 Fuse is intact and tight.

3Door IS closed

4Controls ore set in a running or “On” position

5Start button has been pushed firmly or the power control lever moved upward to start

6Gas