Now start...

1n

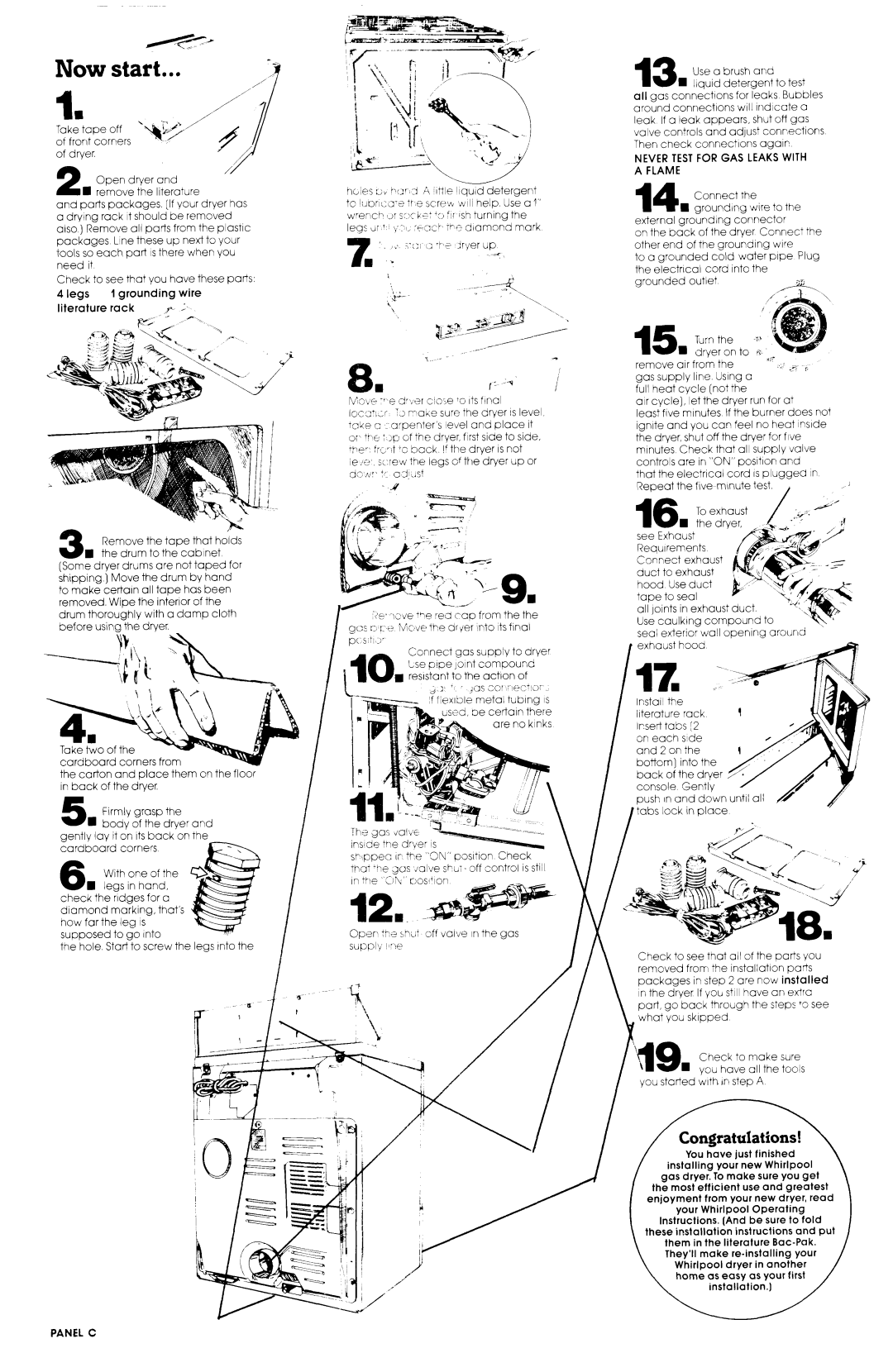

Take tape off of front corners of dryer.

2 Open dryer and

I remove the literature

and parts packages. (If your dryer has a drying rack it should be removed also,) Remove all parts from the plastic packages Line these up next to your tools so each part ISthere when you need it

Check to see that you have these parts:

4 legs | 1 grounding | wire |

literature | rack | ,P- I~ |

n

IL

i

i

13 Use a brush and

n llauid deteraent to test all gas connectlons for leaks Bubbles around connectlons will indicate a leak If a leak appears, shut off gas valve controls and adjust connections Then check connectlons again.

NEVER TEST FOR GAS LEAKS WITH A FLAME

14 Connect the

n grounding wire to the external grounding connector

on the back of the dryer Connect the other end of the grounding wire

to a grounded cold water pipe Plug the electrlcul cord into the grounded outlet

15 Turn the

n dfver on to fl- | SF:. &STc | |

remove air | frorr! the | |

gas supply | line. Using a | .’ |

full heat cycle (not the |

| |

3 Remove the tape that hoids I the drum to the cabinet,

(Some dryer drums are not taped for shipping,) Move the drum by hand to make certain all tape has been removed, Wipe the interior of the drum thoroughly with a damp cloth before using the dryer.

the carton and place them on the floor in back of the dryer.

5 Firmly grasp the

n bodv of the dryer and gently lay it on its back or1the cardboard corners

rv |

| ‘0 Its final |

ioca+:,r | ||

take c :.arpenter’s level and place it ori +pe :~p of the dryer, first side to side, +~IF’, frsrit +c back. !f the dryer is not

ie PII s::rew the legs of the dryer up or

.,’ .

Connect gas supply to dryer

10 Lse p!De joint compound n reslstant to the action of

i

air cycle), let the dryer run for at |

|

least five minutes If the burner does not |

|

ignite and you can feel no heat inside |

|

the dryer, shut off the dryer for five |

|

minutes Check that all supply vuive |

|

controls are in “ON” position and |

|

that the electrical cord ISplugged In | ,i |

Repeat the five minute test. / |

see Exhaust Requirements Connect exhaust duct to exhaust hood Useduct

all joints in exhaust duct. Use caulklncl cornpound to

seal exterior wall opening aroL,nd exhaust hood

Instail the

literature rack ! Ir.sert tabs 12

on each side and 2 on the bottom] into the back of the dryer console Gently Dush In and dowr

I I’tabs lock in place

P/

6 With one of the I legs in hand,

check the ndges for a diamond marking, that’s how fur the leg IS

that *he &IS Jalve sSl;i off control is stiil

In ?‘le “Clh” K~os~+ion\I I

12 R.

supposed to go into

the hole.

Oper ihe G%t off valve in the gas

s(Jppl:; p’-y

IA\

\

/Check to see that all of the parts you removed from the installation parts packages in step 2 are now installed in the dryer If you still have an extru part, go back through the steps +o see

bwhat you skipped

Check to make sure

nyou have all the tools

I you started with in step A

You have just finished installing your new Whirlpool

gas dryer. To make sure you get the most efficient use and greatest enjoyment from your new dryer, read your Whirlpool Operating

Instructions. (And be sure to fold

these installation instructions and put them in the literature

They’ll make