Now Start...

With dryer in laundry area.

![]() WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

![]() exhaust duct

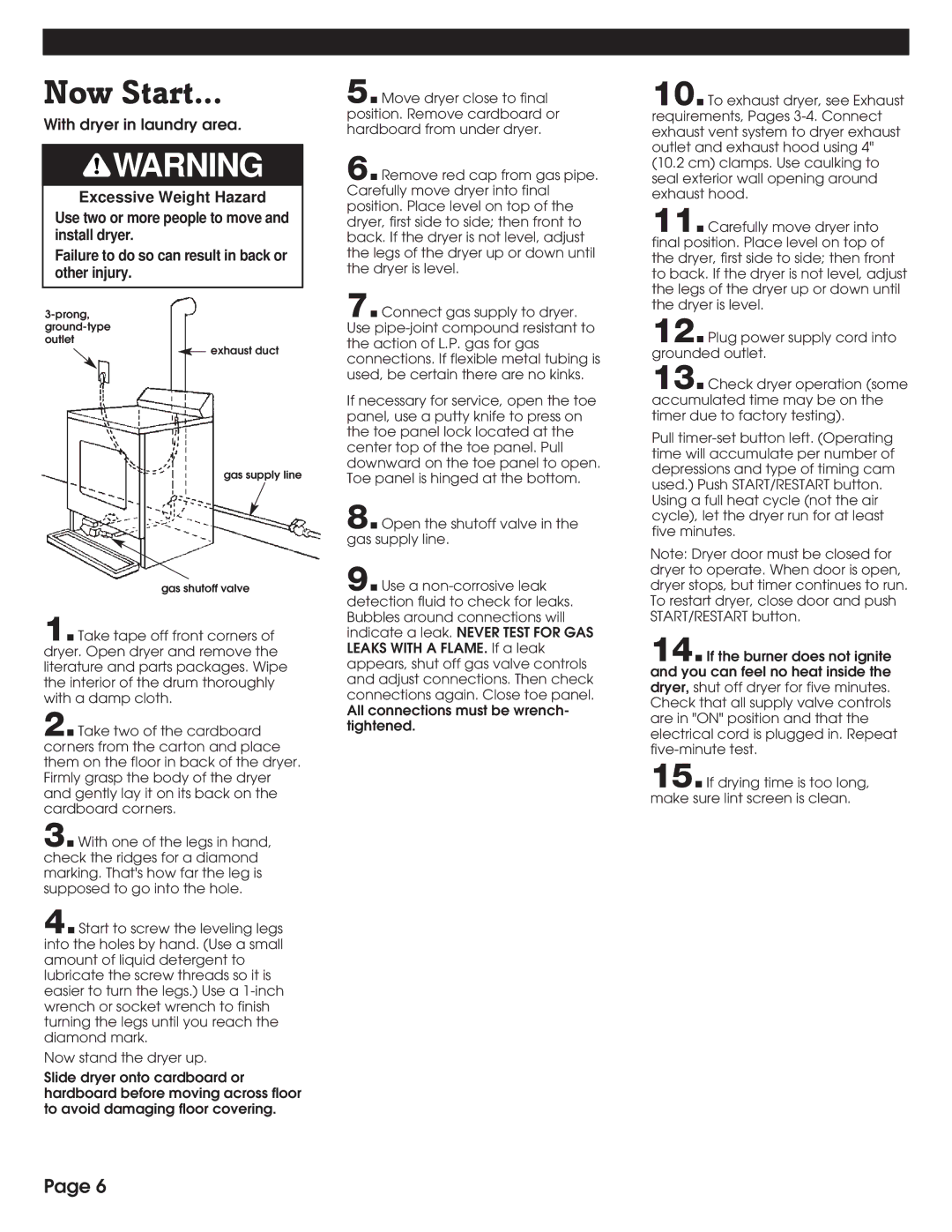

exhaust duct

gas supply line

gas shutoff valve

1.Take tape off front corners of dryer. Open dryer and remove the literature and parts packages. Wipe the interior of the drum thoroughly with a damp cloth.

2.Take two of the cardboard corners from the carton and place them on the floor in back of the dryer. Firmly grasp the body of the dryer and gently lay it on its back on the cardboard corners.

3.With one of the legs in hand, check the ridges for a diamond marking. That's how far the leg is supposed to go into the hole.

4.Start to screw the leveling legs into the holes by hand. (Use a small amount of liquid detergent to lubricate the screw threads so it is easier to turn the legs.) Use a

Now stand the dryer up.

Slide dryer onto cardboard or hardboard before moving across floor to avoid damaging floor covering.

5.Move dryer close to final position. Remove cardboard or hardboard from under dryer.

6.Remove red cap from gas pipe. Carefully move dryer into final position. Place level on top of the dryer, first side to side; then front to back. If the dryer is not level, adjust the legs of the dryer up or down until the dryer is level.

7.Connect gas supply to dryer. Use

If necessary for service, open the toe panel, use a putty knife to press on the toe panel lock located at the center top of the toe panel. Pull downward on the toe panel to open. Toe panel is hinged at the bottom.

8.Open the shutoff valve in the gas supply line.

9.Use a

10.To exhaust dryer, see Exhaust requirements, Pages

(10.2 cm) clamps. Use caulking to seal exterior wall opening around exhaust hood.

11.Carefully move dryer into final position. Place level on top of the dryer, first side to side; then front to back. If the dryer is not level, adjust the legs of the dryer up or down until the dryer is level.

12.Plug power supply cord into grounded outlet.

13.Check dryer operation (some accumulated time may be on the timer due to factory testing).

Pull

Using a full heat cycle (not the air cycle), let the dryer run for at least five minutes.

Note: Dryer door must be closed for dryer to operate. When door is open, dryer stops, but timer continues to run. To restart dryer, close door and push START/RESTART button.

14.If the burner does not ignite and you can feel no heat inside the dryer, shut off dryer for five minutes. Check that all supply valve controls are in "ON" position and that the electrical cord is plugged in. Repeat

15.If drying time is too long, make sure lint screen is clean.

Page 6