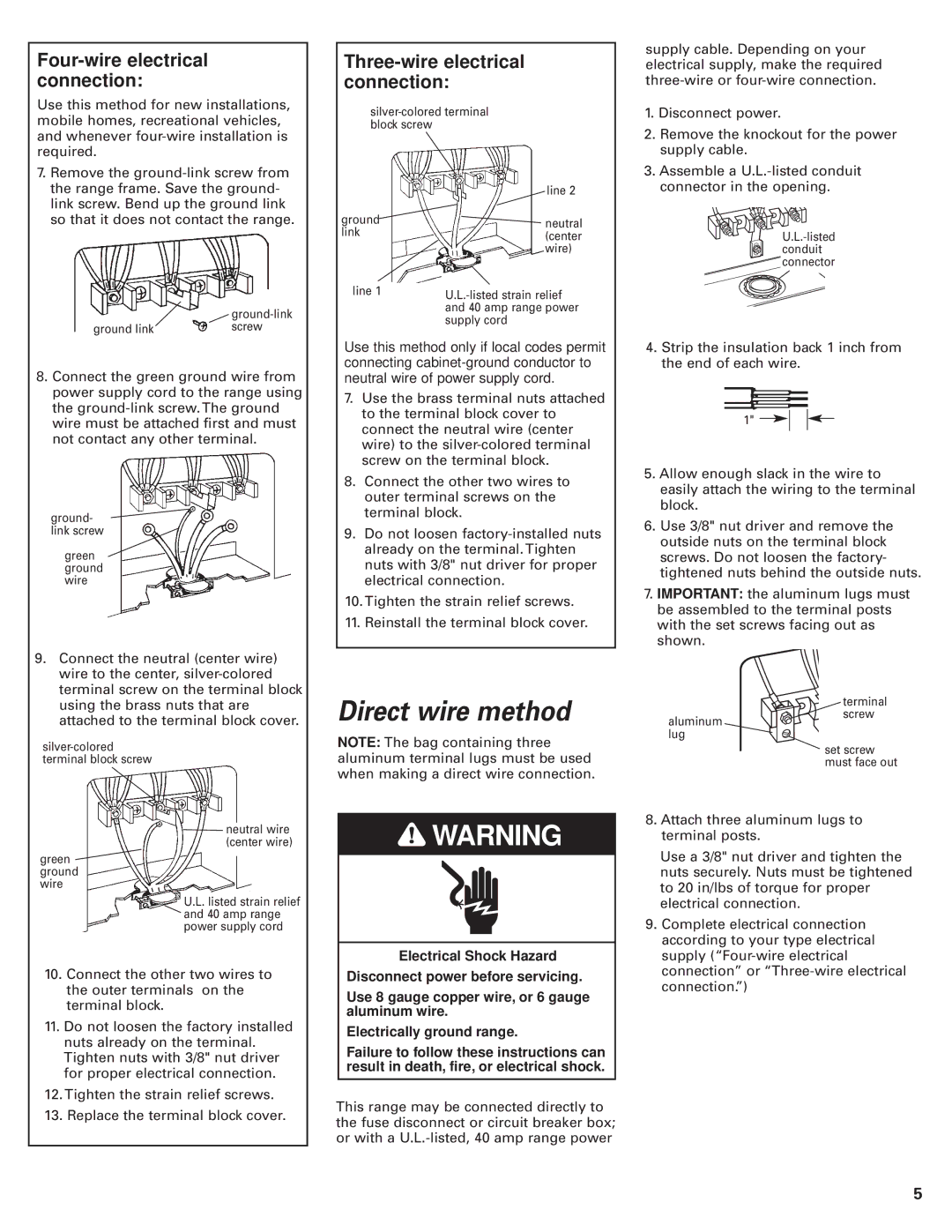

Four-wire electrical connection:

Use this method for new installations, mobile homes, recreational vehicles, and whenever

7.Remove the

| |

ground link | screw |

8.Connect the green ground wire from power supply cord to the range using the

ground- link screw

green ground wire

Three-wire electrical connection:

|

|

| line 2 |

|

ground |

|

|

| |

| neutral | |||

link |

| |||

| (center | |||

|

|

| wire) | |

|

|

|

|

|

|

|

| ||

| line 1 | |||

|

| and 40 amp range power | ||

|

| supply cord | ||

Use this method only if local codes permit connecting

7.Use the brass terminal nuts attached to the terminal block cover to connect the neutral wire (center wire) to the

8.Connect the other two wires to outer terminal screws on the terminal block.

9.Do not loosen

10.Tighten the strain relief screws.

11.Reinstall the terminal block cover.

supply cable. Depending on your electrical supply, make the required

1.Disconnect power.

2.Remove the knockout for the power supply cable.

3.Assemble a

4.Strip the insulation back 1 inch from the end of each wire.

1" ![]()

5.Allow enough slack in the wire to easily attach the wiring to the terminal block.

6.Use 3/8" nut driver and remove the outside nuts on the terminal block screws. Do not loosen the factory- tightened nuts behind the outside nuts.

7.IMPORTANT: the aluminum lugs must be assembled to the terminal posts with the set screws facing out as shown.

9.Connect the neutral (center wire) wire to the center,

Direct wire method

NOTE: The bag containing three

aluminum lug

terminal screw

neutral wire (center wire)

green ![]() ground

ground

wire

U.L. listed strain relief ![]() and 40 amp range

and 40 amp range

power supply cord

10.Connect the other two wires to the outer terminals on the terminal block.

11.Do not loosen the factory installed nuts already on the terminal. Tighten nuts with 3/8" nut driver for proper electrical connection.

12.Tighten the strain relief screws.

13.Replace the terminal block cover.

aluminum terminal lugs must be used when making a direct wire connection.

![]() WARNING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire, or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death, fire, or electrical shock.

This range may be connected directly to the fuse disconnect or circuit breaker box; or with a

![]() set screw must face out

set screw must face out

8.Attach three aluminum lugs to terminal posts.

Use a 3/8" nut driver and tighten the nuts securely. Nuts must be tightened to 20 in/lbs of torque for proper electrical connection.

9.Complete electrical connection according to your type electrical supply

5