3.Open the shutoff valve in the supply line. The valve is open when the handle is parallel to the gas pipe.

A

B

A. Closed valve

B. Open valve

4.Test all connections by brushing on an approved noncorrosive

ConnectVent

1.Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in dryer. If connecting to existing vent, make sure the vent is clean. The dryer vent must fit over the dryer exhaust outlet and inside the exhaust hood. Check that the vent is secured to exhaust hood with a 4" (10.2 cm) clamp.

2.Move dryer into its final location. Do not crush or kink vent.

3.(On gas models) Check that there are no kinks in the flexible gas line.

4.Once the exhaust vent connection is made, remove the corner posts and cardboard.

ConnectInletHose

The dryer must be connected to the cold water faucet using the new inlet hoses. Do not use old hoses.

1.Turn cold water faucet off and remove washer inlet hose.

2.Remove old rubber washer from inlet hose and replace with new rubber washer provided. If space permits, attach the brass female end of the “Y” connector to the cold water faucet.

NOTE: If “Y” connector can be attached directly to cold water faucet, go to Step 6. If “Y” connector cannot be attached directly to the cold water faucet, the short hose must be used. Continue with Step 3.

3.Attach short hose to cold water faucet. Screw on coupling by hand until it is seated on faucet.

4.Using pliers, tighten the couplings with an additional two- thirds turn.

NOTE: Do not overtighten. Damage to the coupling can result.

5.Attach “Y” connector to brass male end of small hose. Screw on coupling by hand until it is seated on connector.

6.Attach straight end of long hose to “Y” connector.

7.Attach washer cold inlet hose to other end of “Y” connector. Screw on coupling by hand until it is seated on connector.

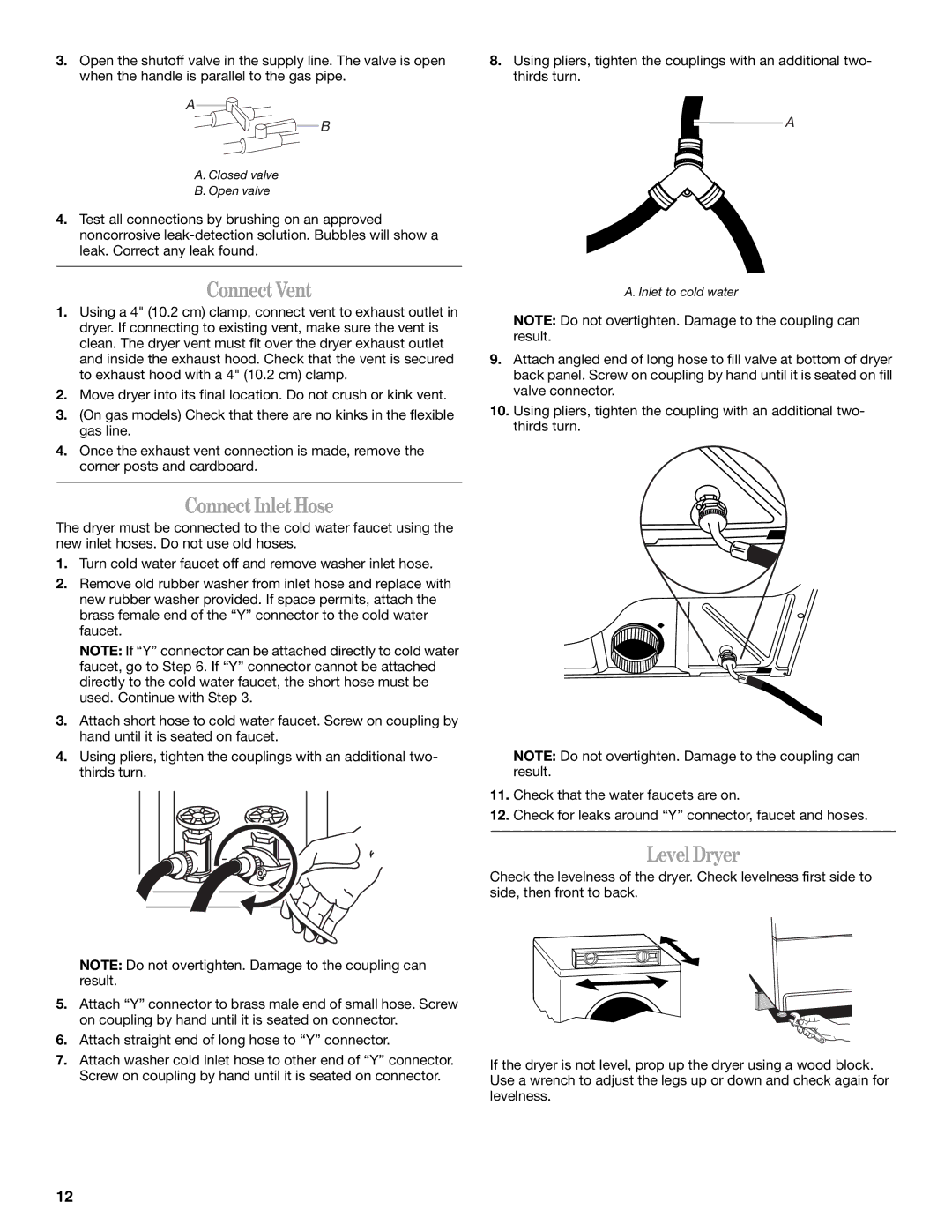

8.Using pliers, tighten the couplings with an additional two- thirds turn.

![]() A

A

A. Inlet to cold water

NOTE: Do not overtighten. Damage to the coupling can result.

9.Attach angled end of long hose to fill valve at bottom of dryer back panel. Screw on coupling by hand until it is seated on fill valve connector.

10.Using pliers, tighten the coupling with an additional two- thirds turn.

NOTE: Do not overtighten. Damage to the coupling can result.

11.Check that the water faucets are on.

12.Check for leaks around “Y” connector, faucet and hoses.

LevelDryer

Check the levelness of the dryer. Check levelness first side to side, then front to back.

If the dryer is not level, prop up the dryer using a wood block. Use a wrench to adjust the legs up or down and check again for levelness.

12