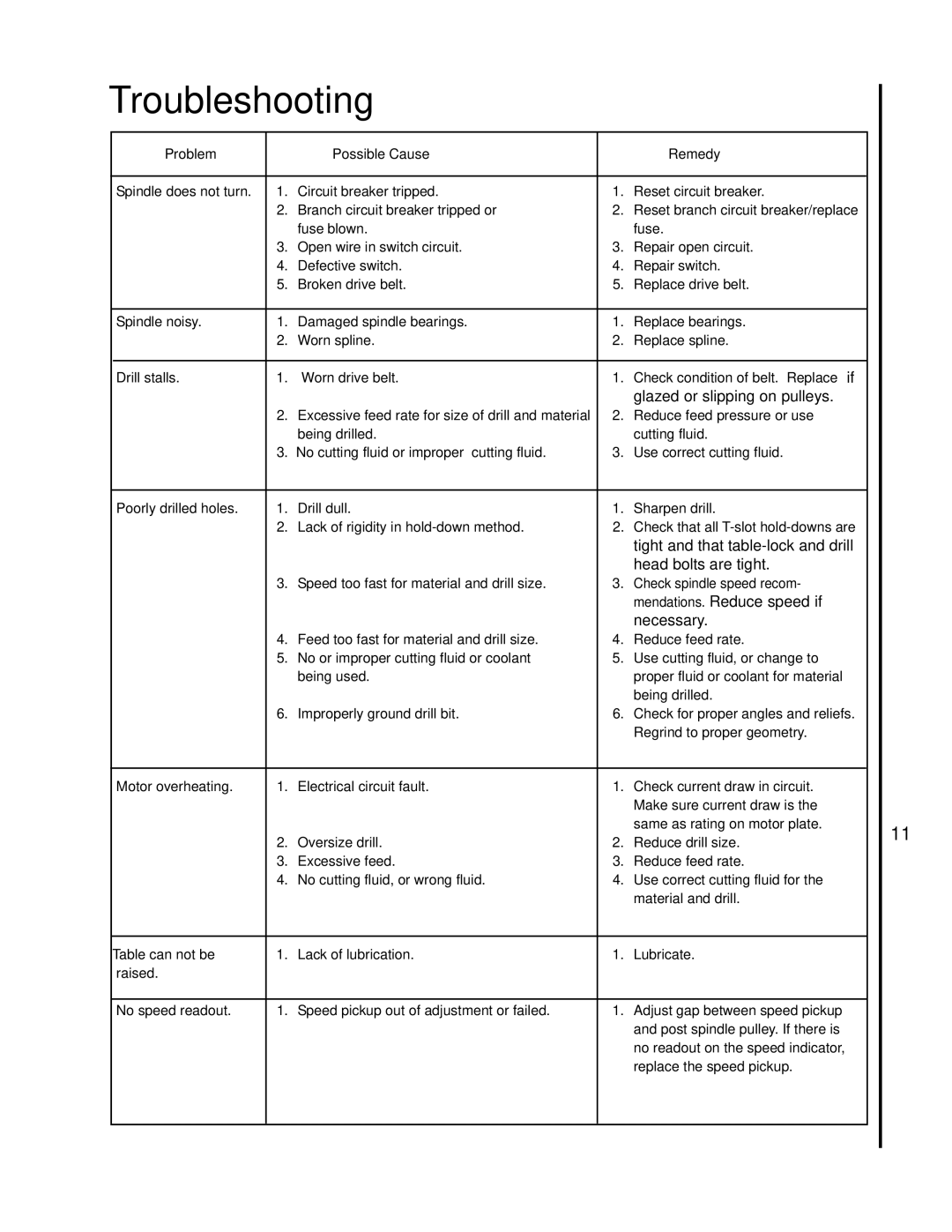

Troubleshooting

Problem |

| Possible Cause |

| Remedy |

|

|

|

|

|

Spindle does not turn. | 1. | Circuit breaker tripped. | 1. | Reset circuit breaker. |

| 2. | Branch circuit breaker tripped or | 2. | Reset branch circuit breaker/replace |

|

| fuse blown. |

| fuse. |

| 3. | Open wire in switch circuit. | 3. | Repair open circuit. |

| 4. | Defective switch. | 4. | Repair switch. |

| 5. | Broken drive belt. | 5. | Replace drive belt. |

|

|

|

|

|

Spindle noisy. | 1. | Damaged spindle bearings. | 1. | Replace bearings. |

| 2. | Worn spline. | 2. | Replace spline. |

|

|

|

|

|

Drill stalls. | 1. | Worn drive belt. | 1. | Check condition of belt. Replace if |

|

|

|

| glazed or slipping on pulleys. |

| 2. | Excessive feed rate for size of drill and material | 2. | Reduce feed pressure or use |

|

| being drilled. |

| cutting fluid. |

| 3. | No cutting fluid or improper cutting fluid. | 3. | Use correct cutting fluid. |

|

|

|

|

|

Poorly drilled holes. | 1. | Drill dull. | 1. | Sharpen drill. |

| 2. | Lack of rigidity in | 2. | Check that all |

|

|

|

| tight and that |

|

|

|

| head bolts are tight. |

| 3. | Speed too fast for material and drill size. | 3. | Check spindle speed recom- |

|

|

|

| mendations. Reduce speed if |

|

|

|

| necessary. |

| 4. | Feed too fast for material and drill size. | 4. | Reduce feed rate. |

| 5. | No or improper cutting fluid or coolant | 5. | Use cutting fluid, or change to |

|

| being used. |

| proper fluid or coolant for material |

|

|

|

| being drilled. |

| 6. | Improperly ground drill bit. | 6. | Check for proper angles and reliefs. |

|

|

|

| Regrind to proper geometry. |

|

|

|

|

|

Motor overheating. | 1. | Electrical circuit fault. | 1. | Check current draw in circuit. |

|

|

|

| Make sure current draw is the |

|

|

|

| same as rating on motor plate. |

| 2. | Oversize drill. | 2. | Reduce drill size. |

| 3. | Excessive feed. | 3. | Reduce feed rate. |

| 4. | No cutting fluid, or wrong fluid. | 4. | Use correct cutting fluid for the |

|

|

|

| material and drill. |

|

|

|

|

|

Table can not be | 1. | Lack of lubrication. | 1. | Lubricate. |

raised. |

|

|

|

|

|

|

|

|

|

No speed readout. | 1. | Speed pickup out of adjustment or failed. | 1. | Adjust gap between speed pickup |

|

|

|

| and post spindle pulley. If there is |

|

|

|

| no readout on the speed indicator, |

|

|

|

| replace the speed pickup. |

|

|

|

|

|

11