STEP 15. The directional handle and threaded rod will fit roofs up to

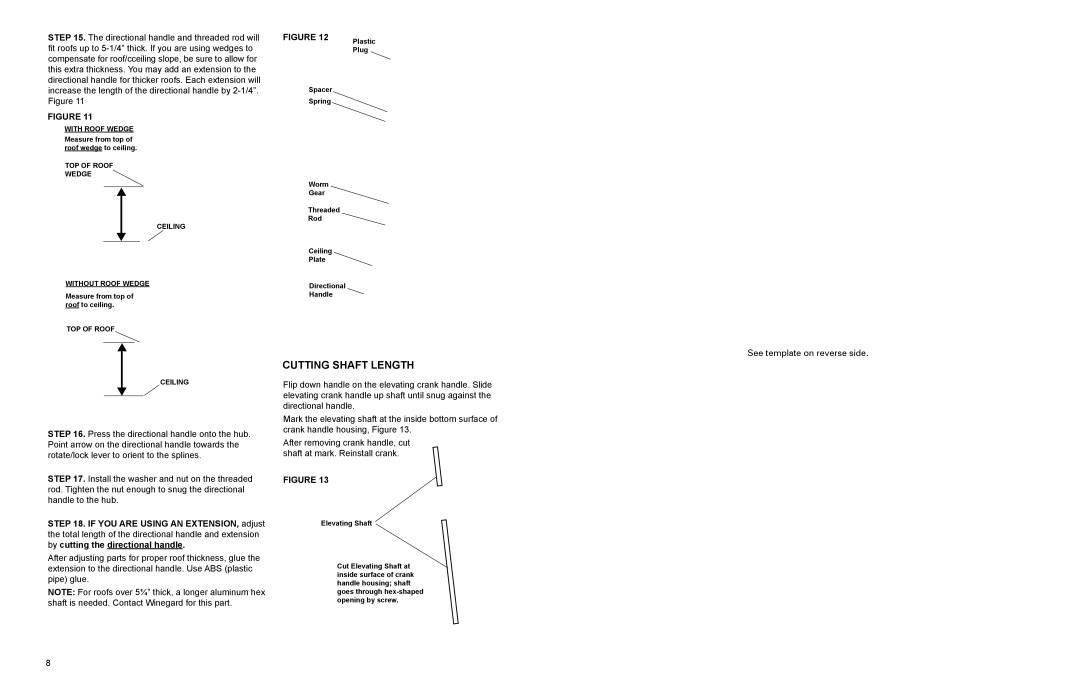

FIGURE 11

WITH ROOF WEDGE

Measure from top of roof wedge to ceiling.

TOP OF ROOF

WEDGE

CEILING

WITHOUT ROOF WEDGE

Measure from top of roof to ceiling.

TOP OF ROOF

CEILING

STEP 16. Press the directional handle onto the hub. Point arrow on the directional handle towards the rotate/lock lever to orient to the splines.

STEP 17. Install the washer and nut on the threaded rod. Tighten the nut enough to snug the directional handle to the hub.

STEP 18. IF YOU ARE USING AN EXTENSION, adjust the total length of the directional handle and extension by cutting the directional handle.

After adjusting parts for proper roof thickness, glue the extension to the directional handle. Use ABS (plastic pipe) glue.

NOTE: For roofs over 5¼” thick, a longer aluminum hex shaft is needed. Contact Winegard for this part.

FIGURE 12 | Plastic |

| Plug |

Spacer

Spring

Worm

Gear

Threaded

Rod

Ceiling

Plate

Directional

Handle

CUTTING SHAFT LENGTH

Flip down handle on the elevating crank handle. Slide elevating crank handle up shaft until snug against the directional handle.

Mark the elevating shaft at the inside bottom surface of crank handle housing, Figure 13.

After removing crank handle, cut shaft at mark. Reinstall crank.

FIGURE 13

Elevating Shaft

Cut Elevating Shaft at inside surface of crank handle housing; shaft goes through

See template on reverse side.

8