Model W1802 2 QT. Professional Spray Gun

6.Set the pressure control knob to regulate the fluid pressure to the gun. Follow material manufacturer's recommendations for this setting.

7.Adjust the atomizing cap to vertical or horizontal. See Atomizing Cap and Fan Adjustments on Page 10 for further explanation.

![]() ��

��

���

8. Trial and error are necessary to achieve the results you want along with a fair amount of practice. Test your material flow and spray pattern on a piece of cardboard or some scrap of material similar to your project.

9.Adjust the fluid control knob to start with a low volume of material and keep the atomization as low as possible. You will need to use a combination of fluid control, inlet air pressure, air flow control and stroke speed to achieve the results you want. Spray so the material wets out nicely without running or sagging.

10.Use the pattern control knob to adjust the spray fan to your desired pattern.

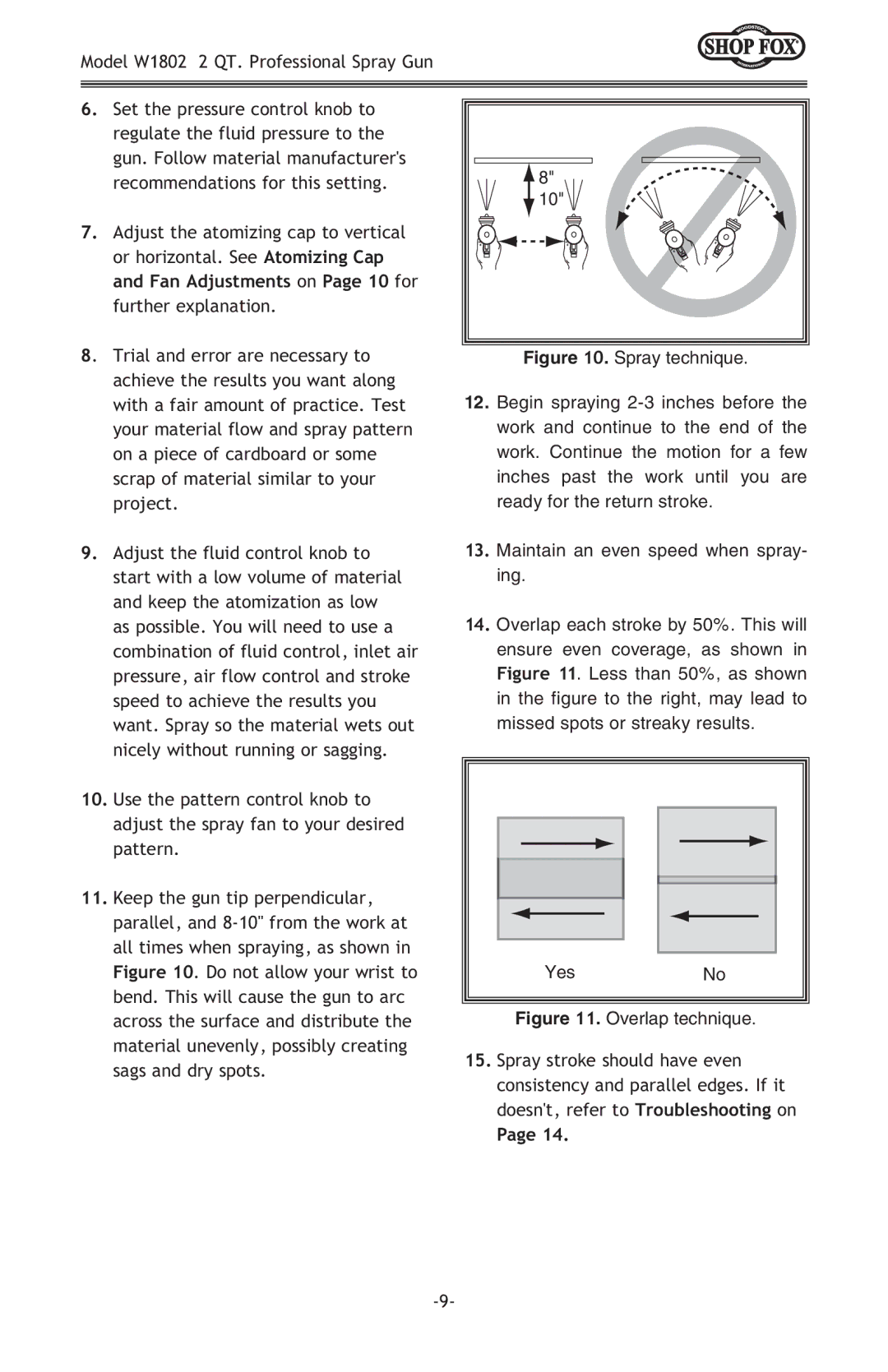

11.Keep the gun tip perpendicular, parallel, and

Figure 10. Spray technique.

12.Begin spraying 2-3 inches before the work and continue to the end of the work. Continue the motion for a few inches past the work until you are ready for the return stroke.

13.Maintain an even speed when spray- ing.

14.Overlap each stroke by 50%. This will ensure even coverage, as shown in Figure 11. Less than 50%, as shown in the figure to the right, may lead to missed spots or streaky results.

YesNo

Figure 11. Overlap technique.

15.Spray stroke should have even consistency and parallel edges. If it doesn't, refer to Troubleshooting on

Page 14.