Model W1802 2 QT. Professional Spray Gun

CLEANING & LUBRICATION

Cleaning

Proper cleaning is the best way to ensure trouble free performance from your spray system. If your system is not thoroughly cleaned, damage and poor spraying will result. Problems caused by improper clean- ing will not be covered by the warranty. Clean the spray gun, hose and pressure cup immediately after each use.

To clean your spray system:

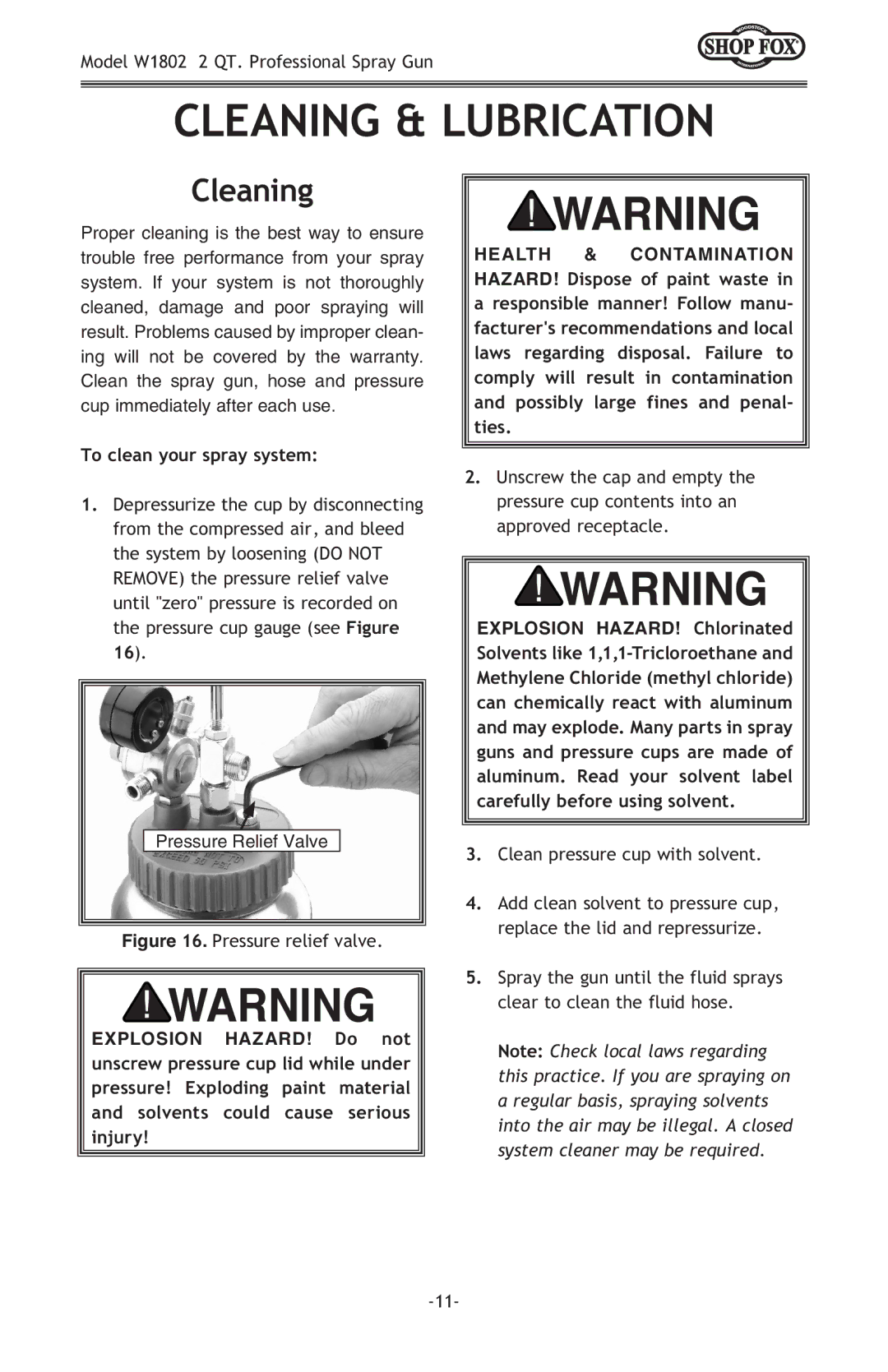

1.Depressurize the cup by disconnecting from the compressed air, and bleed the system by loosening (DO NOT REMOVE) the pressure relief valve until "zero" pressure is recorded on the pressure cup gauge (see Figure 16).

![]()

![]() PressureReliefValve

PressureReliefValve ![]()

![]()

Figure 16. Pressure relief valve.

EXPLOSION HAZARD! Do not unscrew pressure cup lid while under pressure! Exploding paint material and solvents could cause serious injury!

HEALTH & CONTAMINATION HAZARD! Dispose of paint waste in

aresponsible manner! Follow manu- facturer's recommendations and local laws regarding disposal. Failure to comply will result in contamination and possibly large fines and penal- ties.

2.Unscrew the cap and empty the pressure cup contents into an approved receptacle.

EXPLOSION HAZARD! Chlorinated Solvents like

3.Clean pressure cup with solvent.

4.Add clean solvent to pressure cup, replace the lid and repressurize.

5.Spray the gun until the fluid sprays clear to clean the fluid hose.

Note: Check local laws regarding this practice. If you are spraying on a regular basis, spraying solvents into the air may be illegal. A closed system cleaner may be required.