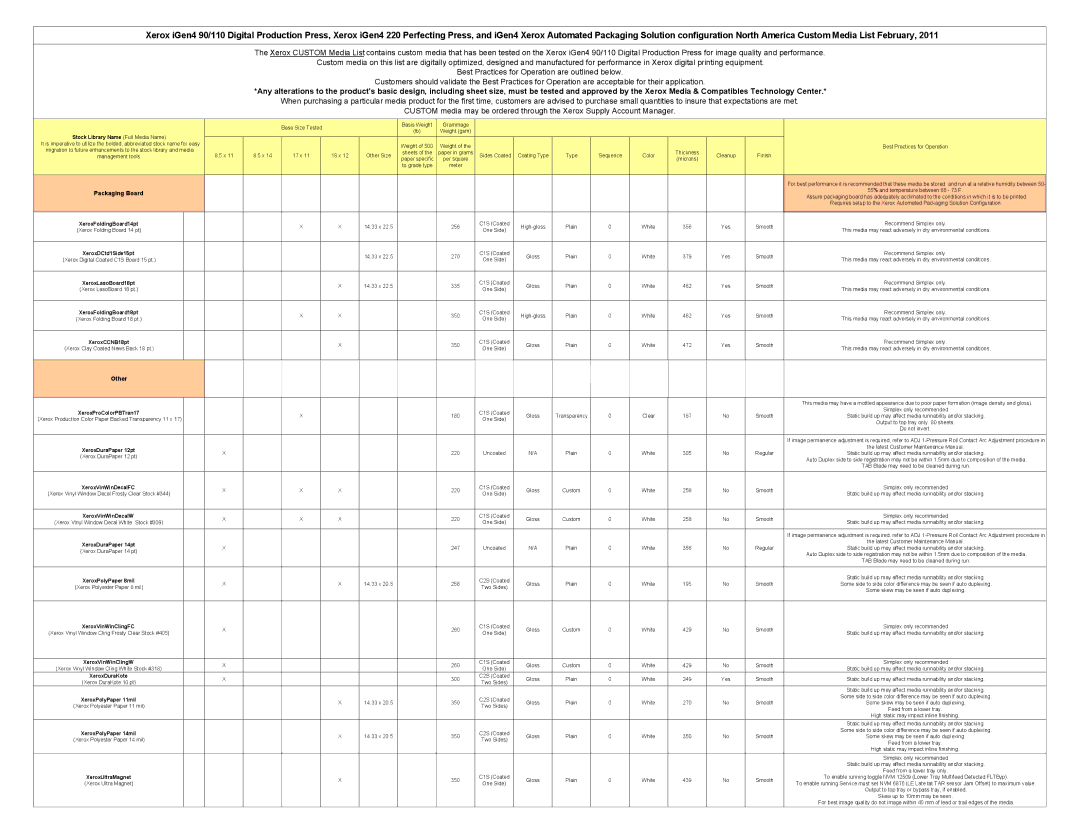

| | | | Base Size Tested | | | Basis Weight | Grammage | | | | | | | | | |

| | | | | | (lb) | Weight (gsm) | | | | | | | | | |

Stock Library Name (Full Media Name) | | | | | | | | | | | | | | | |

It is imperative to utilize the bolded, abbreviated stock name for easy | | | | | | | Weight of 500 | Weight of the | | | | | | | | | Best Practices for Operation |

migration to future enhancements to the stock library and media | | | | | | | | | | | | Thickness | | |

8.5 x 11 | 8.5 x 14 | 17 x 11 | | 18 x 12 | Other Size | sheets of the | paper in grams | Sides Coated | Coating Type | Type | Sequence | Color | Cleanup | Finish | |

management tools. | | |

| paper specific | per square | (microns) | |

| | | | | | | | | | | | | | | |

| | | | | | | | to grade type | meter | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | For best performance it is recommended that these media be stored and run at a relative humidity between 50- |

Packaging Board | | | | | | | | | | | | | | | | | 55% and temperature between 68 - 73 F. |

| | | | | | | | | | | | | | | | Assure packaging board has adequately acclimated to the conditions in which it is to be printed. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Requires setup to the Xerox Automated Packaging Solution Configuration. |

| | | | | | | | | | | | | | | | | | |

XeroxFoldingBoard14pt | | | | X | | X | 14.33 x 22.5 | | 256 | C1S (Coated | High-gloss | Plain | 0 | White | 356 | Yes | Smooth | Recommend Simplex only. |

(Xerox Folding Board 14 pt) | | | | | | One Side) | This media may react adversely in dry environmental conditions. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxDCtd1Side15pt | | | | | | | 14.33 x 22.5 | | 270 | C1S (Coated | Gloss | Plain | 0 | White | 379 | Yes | Smooth | Recommend Simplex only. |

(Xerox Digital Coated C1S Board 15 pt.) | | | | | | | | One Side) | This media may react adversely in dry environmental conditions. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxLasoBoard18pt | | | | | | X | 14.33 x 22.5 | | 335 | C1S (Coated | Gloss | Plain | 0 | White | 462 | Yes | Smooth | Recommend Simplex only. |

(Xerox LasoBoard 18 pt.) | | | | | | | One Side) | This media may react adversely in dry environmental conditions. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxFoldingBoard18pt | | | | X | | X | | | 350 | C1S (Coated | High-gloss | Plain | 0 | White | 462 | Yes | Smooth | Recommend Simplex only. |

(Xerox Folding Board 18 pt.) | | | | | | | One Side) | This media may react adversely in dry environmental conditions. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxCCNB18pt | | | | | | X | | | 350 | C1S (Coated | Gloss | Plain | 0 | White | 472 | Yes | Smooth | Recommend Simplex only. |

(Xerox Clay Coated News Back 18 pt.) | | | | | | | | One Side) | This media may react adversely in dry environmental conditions. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

Other | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | This media may have a mottled appearance due to poor paper formation (image density and gloss). |

XeroxProColorPBTran17 | | | | X | | | | | 180 | C1S (Coated | Gloss | Transparency | 0 | Clear | 187 | No | Smooth | Simplex only recommended |

| | | | | | | Static build up may affect media runnability and/or stacking. |

(Xerox Production Color Paper Backed Transparency 11 x 17) | | | | | | | | One Side) |

| | | | | | | | | | | | | | | | Output to top tray only. 80 sheets. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Do not invert. |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in |

XeroxDuraPaper 12pt | | | | | | | | | | | | | | | | | | the latest Customer Maintenance Manual. |

| X | | | | | | | 220 | Uncoated | N/A | Plain | 0 | White | 305 | No | Regular | Static build up may affect media runnability and/or stacking. |

(Xerox DuraPaper 12 pt) | | | | | | | |

| | | | | | | | | | | | | | | | | Auto Duplex side to side registration may not be within 1.5mm due to composition of the media. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | TAB Blade may need to be cleaned during run. |

| | | | | | | | | | | | | | | | | | |

XeroxVinWinDecalFC | | X | | X | | X | | | 220 | C1S (Coated | Gloss | Custom | 0 | White | 258 | No | Smooth | Simplex only recommended |

(Xerox Vinyl Window Decal Frosty Clear Stock #344) | | | | | | One Side) | Static build up may affect media runnability and/or stacking. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxVinWinDecalW | | X | | X | | X | | | 220 | C1S (Coated | Gloss | Custom | 0 | White | 258 | No | Smooth | Simplex only recommended |

(Xerox Vinyl Window Decal White Stock #309) | | | | | | One Side) | Static build up may affect media runnability and/or stacking. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure in |

XeroxDuraPaper 14pt | | X | | | | | | | 247 | Uncoated | N/A | Plain | 0 | White | 356 | No | Regular | the latest Customer Maintenance Manual. |

| | | | | | | Static build up may affect media runnability and/or stacking. |

(Xerox DuraPaper 14 pt) | | | | | | | |

| | | | | | | | | | | | | | | | | Auto Duplex side to side registration may not be within 1.5mm due to composition of the media. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | TAB Blade may need to be cleaned during run. |

| | | | | | | | | | | | | | | | | | |

XeroxPolyPaper 8mil | | | | | | | | | | C2S (Coated | | | | | | | | Static build up may affect media runnability and/or stacking. |

| X | | | | X | 14.33 x 20.5 | | 258 | Gloss | Plain | 0 | White | 195 | No | Smooth | Some side to side color difference may be seen if auto duplexing. |

(Xerox Polyester Paper 8 mil) | | | | | | Two Sides) |

| | | | | | | | | | | | | | | | Some skew may be seen if auto duplexing. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxVinWinClingFC | | X | | | | | | | 260 | C1S (Coated | Gloss | Custom | 0 | White | 429 | No | Smooth | Simplex only recommended |

(Xerox Vinyl Window Cling Frosty Clear Stock #405) | | | | | | | | One Side) | Static build up may affect media runnability and/or stacking. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxVinWinClingW | | X | | | | | | | 260 | C1S (Coated | Gloss | Custom | 0 | White | 429 | No | Smooth | Simplex only recommended |

(Xerox Vinyl Window Cling White Stock #318) | | | | | | | | One Side) | Static build up may affect media runnability and/or stacking. |

| | | | | | | | | | | | | | | |

XeroxDuraKote | | X | | | | | | | 300 | C2S (Coated | Gloss | Plain | 0 | White | 249 | Yes | Smooth | Static build up may affect media runnability and/or stacking. |

(Xerox DuraKote 10 pt) | | | | | | | | Two Sides) |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Static build up may affect media runnability and/or stacking. |

XeroxPolyPaper 11mil | | | | | | X | 14.33 x 20.5 | | 350 | C2S (Coated | Gloss | Plain | 0 | White | 270 | No | Smooth | Some side to side color difference may be seen if auto duplexing. |

| | | | | | Some skew may be seen if auto duplexing. |

(Xerox Polyester Paper 11 mil) | | | | | | | Two Sides) |

| | | | | | | | | | | | | | | | Feed from a lower tray. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | High static may impact inline finishing. |

| | | | | | | | | | | | | | | | | | Static build up may affect media runnability and/or stacking. |

XeroxPolyPaper 14mil | | | | | | X | 14.33 x 20.5 | | 350 | C2S (Coated | | | | | | | | Some side to side color difference may be seen if auto duplexing. |

| | | | | | Gloss | Plain | 0 | White | 350 | No | Smooth | Some skew may be seen if auto duplexing. |

(Xerox Polyester Paper 14 mil) | | | | | | | Two Sides) |

| | | | | | | | | | | | | | | | Feed from a lower tray. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | High static may impact inline finishing. |

| | | | | | | | | | | | | | | | | | Simplex only recommended |

| | | | | | | | | | | | | | | | | | Static build up may affect media runnability and/or stacking. |

| | | | | | | | | | C1S (Coated | | | | | | | | Feed from a lower tray only. |

XeroxUltraMagnet | | | | | | X | | | 350 | Gloss | Plain | 0 | White | 439 | No | Smooth | To enable running toggle NVM 12509 (Lower Tray Multifeed Detected FLTByp). |

(Xerox Ultra Magnet) | | | | | | | | One Side) | To enable running Service must set NVM 6876 (LE Late tat TAR sensor Jam Offset) to maximum value. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Output to top tray or bypass tray, if enabled. |

| | | | | | | | | | | | | | | | | | Skew up to 10mm may be seen. |

| | | | | | | | | | | | | | | | | | For best image quality do not image within 40 mm of lead or trail edges of the media. |