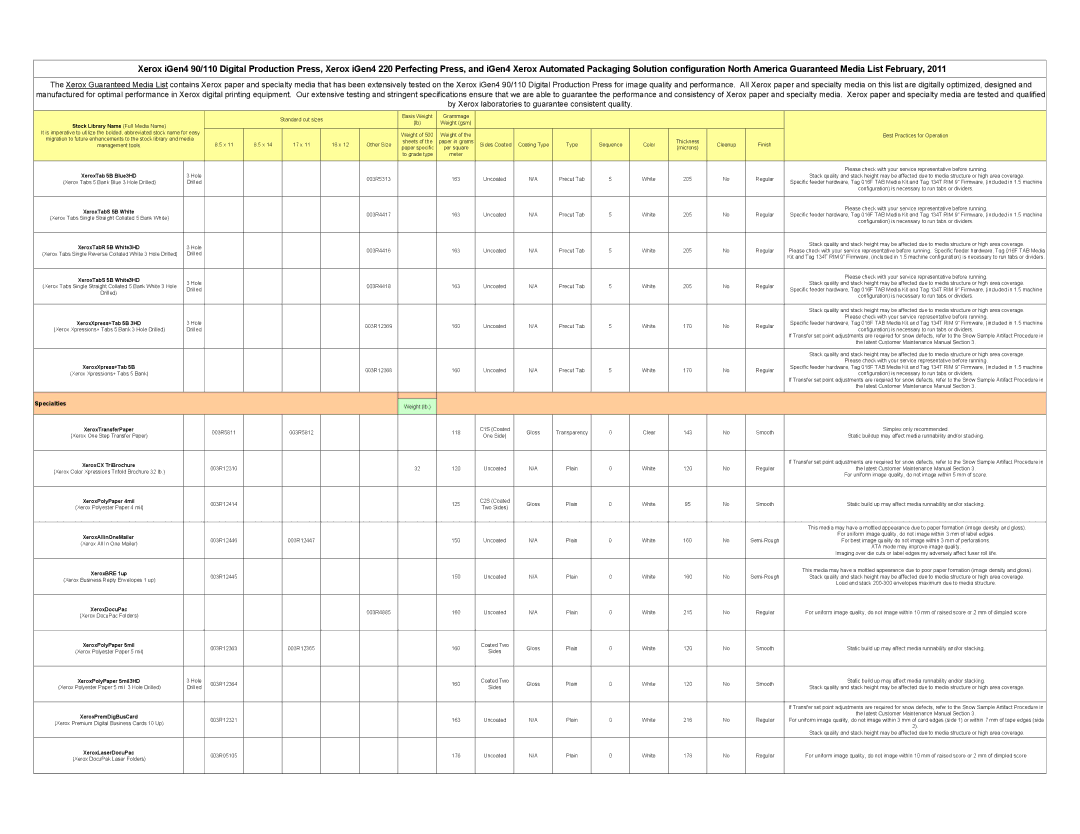

| | | | Standard cut sizes | | | Basis Weight | Grammage | | | | | | | | | |

Stock Library Name (Full Media Name) | | | | | | (lb) | Weight (gsm) | | | | | | | | | |

| | | | | | | | | | | | | | | |

It is imperative to utilize the bolded, abbreviated stock name for easy | | | | | | | Weight of 500 | Weight of the | | | | | | | | | Best Practices for Operation |

migration to future enhancements to the stock library and media | | | | | | | | | | | | | | |

8.5 x 11 | 8.5 x 14 | 17 x 11 | | 18 x 12 | Other Size | sheets of the | paper in grams | Sides Coated | Coating Type | Type | Sequence | Color | Thickness | Cleanup | Finish | |

management tools. | | | |

| | paper specific | per square | (microns) | |

| | | | | | | | | | | | | | | |

| | | | | | | | to grade type | meter | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Please check with your service representative before running. |

XeroxTab 5B Blue3HD | 3 Hole | | | | | | 003R5313 | | 163 | Uncoated | N/A | Precut Tab | 5 | White | 205 | No | Regular | Stack quality and stack height may be affected due to media structure or high area coverage. |

(Xerox Tabs 5 Bank Blue 3 Hole Drilled) | Drilled | | | | | | | Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | configuration) is necessary to run tabs or dividers. |

| | | | | | | | | | | | | | | | | | |

XeroxTabS 5B White | | | | | | | | | | | | | | | | | | Please check with your service representative before running. |

| | | | | | 003R4417 | | 163 | Uncoated | N/A | Precut Tab | 5 | White | 205 | No | Regular | Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine |

(Xerox Tabs Single Straight Collated 5 Bank White) | | | | | | | |

| | | | | | | | | | | | | | | | | configuration) is necessary to run tabs or dividers. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxTabR 5B White3HD | 3 Hole | | | | | | | | | | | | | | | | | Stack quality and stack height may be affected due to media structure or high area coverage. |

| | | | | 003R4416 | | 163 | Uncoated | N/A | Precut Tab | 5 | White | 205 | No | Regular | Please check with your service representative before running. Specific feeder hardware, Tag 016F TAB Media |

(Xerox Tabs Single Reverse Collated White 3 Hole Drilled) | Drilled | | | | | | |

| | | | | | | | | | | | | | | | Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine configuration) is necessary to run tabs or dividers. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxTabS 5B White3HD | | | | | | | | | | | | | | | | | | Please check with your service representative before running. |

3 Hole | | | | | | | | | | | | | | | | | Stack quality and stack height may be affected due to media structure or high area coverage. |

(Xerox Tabs Single Straight Collated 5 Bank White 3 Hole | | | | | | 003R4418 | | 163 | Uncoated | N/A | Precut Tab | 5 | White | 205 | No | Regular |

Drilled | | | | | | | Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine |

Drilled) | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | configuration) is necessary to run tabs or dividers. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Stack quality and stack height may be affected due to media structure or high area coverage. |

| | | | | | | | | | | | | | | | | | Please check with your service representative before running. |

XeroxXpress+Tab 5B 3HD | 3 Hole | | | | | | 003R12369 | | 160 | Uncoated | N/A | Precut Tab | 5 | White | 170 | No | Regular | Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine |

(Xerox Xpressions+ Tabs 5 Bank 3 Hole Drilled) | Drilled | | | | | | | configuration) is necessary to run tabs or dividers. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in |

| | | | | | | | | | | | | | | | | | the latest Customer Maintenance Manual Section 3. |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Stack quality and stack height may be affected due to media structure or high area coverage. |

| | | | | | | | | | | | | | | | | | Please check with your service representative before running. |

XeroxXpress+Tab 5B | | | | | | | 003R12368 | | 160 | Uncoated | N/A | Precut Tab | 5 | White | 170 | No | Regular | Specific feeder hardware, Tag 016F TAB Media Kit and Tag 134T RIM 9" Firmware, (included in 1.5 machine |

(Xerox Xpressions+ Tabs 5 Bank) | | | | | | | | configuration) is necessary to run tabs or dividers. |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in |

| | | | | | | | | | | | | | | | | | the latest Customer Maintenance Manual Section 3. |

| | | | | | | | | | | | | | | | | | |

Specialties | | | | | | | | | | | | | | | | | | |

| | | | | | | Weight (lb.) | | | | | | | | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxTransferPaper | | 003R5811 | | 003R5812 | | | | | 118 | C1S (Coated | Gloss | Transparency | 0 | Clear | 143 | No | Smooth | Simplex only recommended. |

(Xerox One Step Transfer Paper) | | | | | | | One Side) | Static buildup may affect media runnability and/or stacking. |

| | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxCX TriBrochure | | | | | | | | | | | | | | | | | | If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in |

| 003R12310 | | | | | | 32 | 120 | Uncoated | N/A | Plain | 0 | White | 120 | No | Regular | the latest Customer Maintenance Manual Section 3. |

(Xerox Color Xpressions Trifold Brochure 32 lb.) | | | | | | |

| | | | | | | | | | | | | | | | | For uniform image quality, do not image within 5 mm of score. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxPolyPaper 4mil | | 003R12414 | | | | | | | 125 | C2S (Coated | Gloss | Plain | 0 | White | 95 | No | Smooth | Static build up may affect media runnability and/or stacking. |

(Xerox Polyester Paper 4 mil) | | | | | | | | Two Sides) |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | This media may have a mottled appearance due to paper formation (image density and gloss). |

XeroxAllinOneMailer | | | | | | | | | | | | | | | | | | For uniform image quality, do not image within 3 mm of label edges. |

| 003R12446 | | 003R12447 | | | | | 150 | Uncoated | N/A | Plain | 0 | White | 160 | No | Semi-Rough | For best image quality do not image within 3 mm of perforations. |

(Xerox All In One Mailer) | | | | | | |

| | | | | | | | | | | | | | | | | ATA mode may improve image quality. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Imaging over die cuts or label edges my adversely affect fuser roll life. |

| | | | | | | | | | | | | | | | | | |

XeroxBRE 1up | | | | | | | | | | | | | | | | | | This media may have a mottled appearance due to poor paper formation (image density and gloss). |

| 003R12445 | | | | | | | 150 | Uncoated | N/A | Plain | 0 | White | 160 | No | Semi-Rough | Stack quality and stack height may be affected due to media structure or high area coverage. |

(Xerox Business Reply Envelopes 1 up) | | | | | | | |

| | | | | | | | | | | | | | | | | Load and stack 200-300 envelopes maximum due to media structure. |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxDocuPac | | | | | | | 003R4885 | | 160 | Uncoated | N/A | Plain | 0 | White | 215 | No | Regular | For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score |

(Xerox DocuPac Folders) | | | | | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxPolyPaper 5mil | | 003R12363 | | 003R12365 | | | | | 160 | Coated Two | Gloss | Plain | 0 | White | 120 | No | Smooth | Static build up may affect media runnability and/or stacking. |

(Xerox Polyester Paper 5 mil) | | | | | | | Sides |

| | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

XeroxPolyPaper 5mil3HD | 3 Hole | 003R12364 | | | | | | | 160 | Coated Two | Gloss | Plain | 0 | White | 120 | No | Smooth | Static build up may affect media runnability and/or stacking. |

(Xerox Polyester Paper 5 mil 3 Hole Drilled) | Drilled | | | | | | | Sides | Stack quality and stack height may be affected due to media structure or high area coverage. |

| | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | If Transfer set point adjustments are required for snow defects, refer to the Snow Sample Artifact Procedure in |

XeroxPremDigBusCard | | 003R12321 | | | | | | | 163 | Uncoated | N/A | Plain | 0 | White | 216 | No | Regular | the latest Customer Maintenance Manual Section 3. |

| | | | | | | For uniform image quality, do not image within 3 mm of card edges (side 1) or within 7 mm of tape edges (side |

(Xerox Premium Digital Business Cards 10 Up) | | | | | | | |

| | | | | | | | | | | | | | | | | 2). |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | Stack quality and stack height may be affected due to media structure or high area coverage. |

| | | | | | | | | | | | | | | | | | |

XeroxLaserDocuPac | | 003R05105 | | | | | | | 176 | Uncoated | N/A | Plain | 0 | White | 178 | No | Regular | For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score |

(Xerox DocuPak Laser Folders) | | | | | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | |