8560 specifications

The Xerox 8560 is an advanced color laser printer that exemplifies reliability and high-performance printing solutions tailored for demanding office environments. Known for its impressive speed and vivid output quality, the Xerox 8560 is widely recognized for its ability to handle large print volumes without compromising on quality.One of the standout features of the Xerox 8560 is its print speed. Capable of producing up to 45 pages per minute for black and white documents and up to 40 pages per minute for color prints, the printer is designed to enhance productivity. This performance allows teams to meet tight deadlines without experiencing bottlenecks.

The printer’s advanced resolution of up to 1200 x 2400 dpi ensures that images and text are crisp and clear, making it ideal for producing marketing materials, presentations, and professional documents. This high-resolution capability is complemented by the printer’s ability to handle various media types and sizes, including envelopes, labels, and heavy cardstock, providing versatility for an array of print jobs.

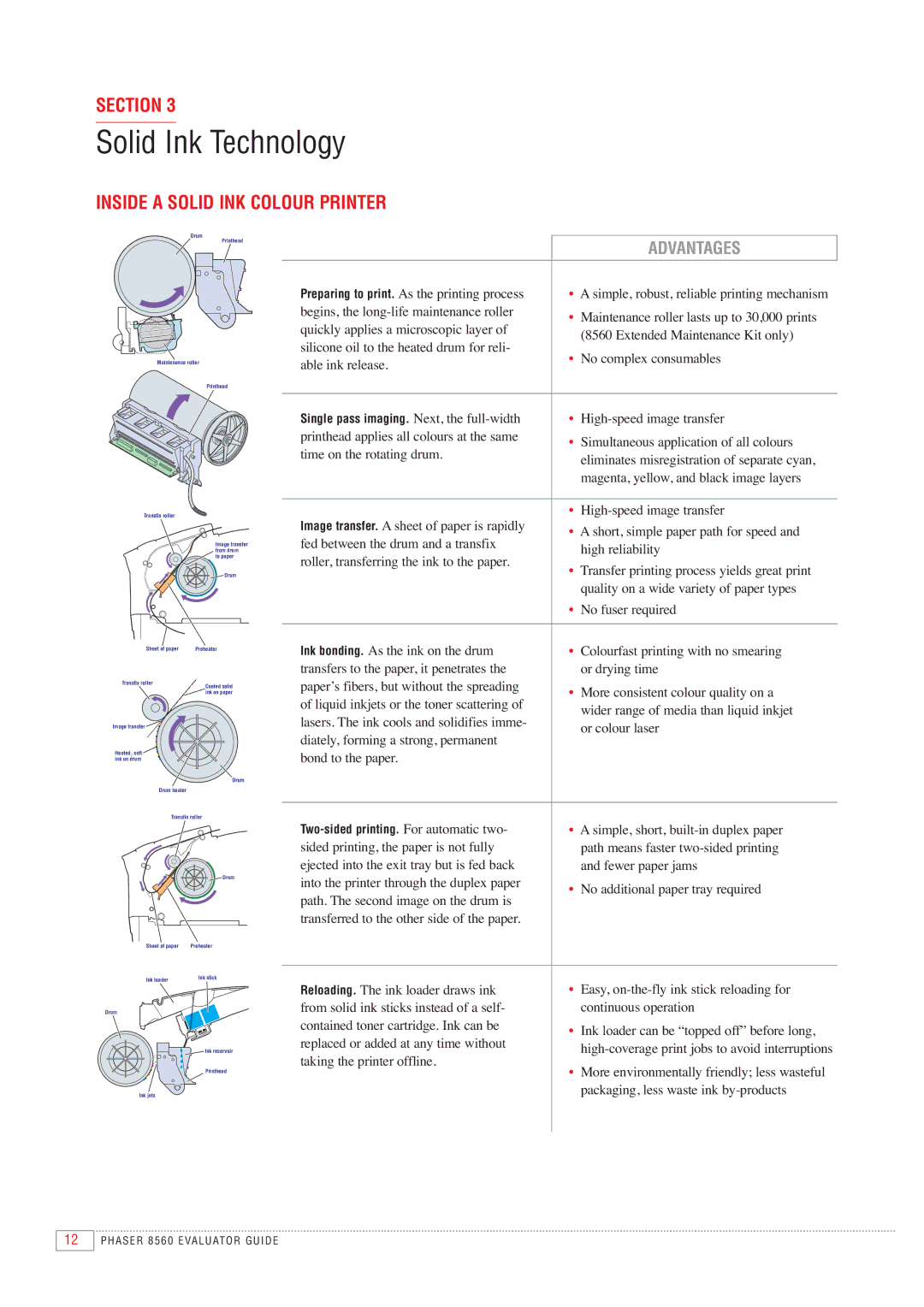

Incorporating Xerox's proprietary solid ink technology, the Xerox 8560 utilizes solid sticks of ink rather than traditional cartridges. This unique approach not only enhances the quality of color output but also reduces waste, as users can benefit from more efficient ink usage. The vivid colors produced are especially advantageous for color-intensive applications, where striking visuals are essential.

Another key characteristic of the Xerox 8560 is its connectivity options. It supports USB, Ethernet, and Wi-Fi, enabling seamless integration into any office network. Additionally, it supports mobile printing technologies, including Apple AirPrint and Google Cloud Print, allowing users to print documents directly from their smartphones or tablets.

The user-friendly interface, characterized by a large color touch screen, simplifies navigation and operation. The printer also includes features such as duplex printing, which automatically prints on both sides of the paper, contributing to cost savings and environmental sustainability.

Lastly, security features such as password protection and secure printing options ensure that sensitive documents are protected, making the Xerox 8560 a trusted choice for organizations that prioritize data security. With its blend of speed, quality, and advanced technologies, the Xerox 8560 stands out as a robust solution for any business looking to enhance its printing capabilities.