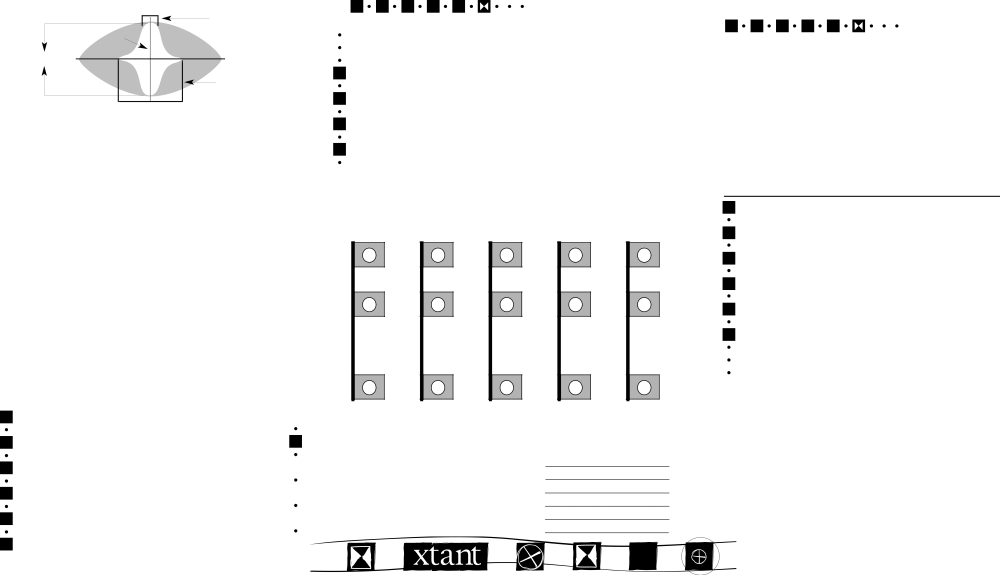

P A R A M E T R I C E Q U A L I Z A T I O N

x t a n t t e c h n o l o g i e s

CENTER FREQUENCY

RANGE OF BOOST/CUT

HIGH “Q”: A NARROW RANGE OF FREQUENCIES (ON EITHER SIDE OF THE CENTER FREQUENCY) ARE AFFECTED BY EQUALIZATION.

LOW “Q”: A WIDER RANGE OF FRE- QUENCIES (ON EITHER SIDE OF THE CENTER FREQUENCY) ARE AFFECT- ED BY EQUALIZATION.

I N S T A L L E R ’ S R E F E R E N C E L O G

| | | | | | | | |

D A T E I N S T A L L E D: | | | | | |

O W N E R’ S N A M E: | | | | | P HONE: | |

A D D R E S S: | | | | | | |

CI T Y/ ST A T E: | | | ZI P: | |

INSTALLER’S REFERENCE

TH I S D O C U M E N T H A S B E E N C R A F T E D T O M A K E I N S T A L L A- T I O N, SYSTEM D E S I G N A N D T R O U B L E- S H O O T I N G, A Q U I C K A N D E A S Y PROCESS. TH E C H A R T S P R O V I D E D, O F F E R A S I M- P L E M E T H O D O F D O C U M E N T A T I O N.

T h e P 5 0 0 i s a 5 - b a n d p a r a m e t r i c e q u a l i z e r . I t s d e s i g n a l l o w s t h e u s e r t o v a r y c e n t e r f r e q u e n c y , s e l e c t a “ Q ” o f 1 - 1 0 , a n d s e l e c t u p t o 1 8 d B o f b o o s t o r c u t .

CENTER FREQUENCIES range from 20 Hz to 20 KHz. The on- b o a r d f r e q u e n c y j u m p e r d i v i d e s t h e f r e q u e n c y r a n g e i n t o t h r e e bands: 20 Hz to 200 Hz, 200 Hz to 2 KHz, and 2 KHz to 20 KHz. Simply place the jumper in one of the three positions which cor- responds with the frequency to be adjusted . The specific fre- quency is then selected via the “frequency” potentiometer

“Q” d e t e r m i n e s t h e r a n g e o f f r e q u e n c i e s a f f e c t e d o n e i t h e r s i d e o f t h e c e n t e r f r e q u e n c y . “Q ” i s e q u a l t o t h e c e n t e r f r e- q u e n c y d i v i d e d b y t h e b a n d w i d t h . A s “ Q ” g o e s u p , b a n d w i d t h decreases . The P500’s “Q” adjustment ranges from a narrow bandwidth of 10 to a very broad bandwidth of 1 .

V E H I C L E: | | | | | | | YE A R: | |

| | | | | | | | | |

XT A N T P 5 0 0 S E R I A L# | | | | | | | | |

MODES OF OPERATION: ( C I R C L E S E T T I N G) | | | | |

I N P U T M O D E: | | 4 C H A N N E L | 2 C H A N N E L | |

B A L A N C E D L I N E: | E N A B L E | | D I S A B L E | | | | |

N O I S E G A T E: | | O N | | D E F E A T | | | | |

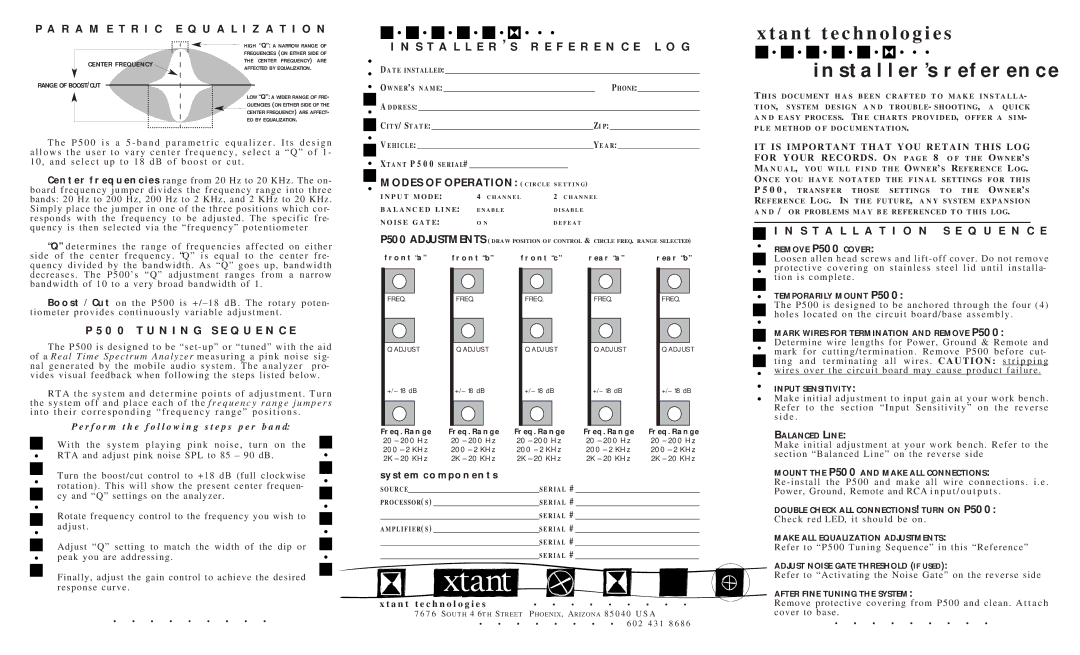

P500 ADJUSTMENTS ( DRAW POSITION O F CONTROL & CIRCLE FREQ. RANGE SELECTED) |

FRONT “A” | FRONT “B” | FRONT “C” | REAR “A” | REAR “B” |

I T I S I M P O R T A N T T H A T Y O U R E T A I N T H I S L O G FOR YOUR RECORDS . O N P A G E 8 O F T H E OW N E R’ S

MA N U A L, Y O U W I L L F I N D T H E OW N E R’ S RE F E R E N C E LOG. ON C E Y O U H A V E N O T A T E D T H E F I N A L S E T T I N G S F O R T H I S P 5 0 0 , T R A N S F E R T H O S E S E T T I N G S T O T H E OW N E R’ S RE F E R E N C E LOG. IN T H E F U T U R E, A N Y SYSTEM E X P A N S I O N A N D / O R PROBLEMS M A Y B E REFERENCED T O T H I S LOG.

I N S T A L L A T I O N S E Q U E N C E

REMOVE P500 COVER:

Loosen allen head screws and lift - off cover . Do not remove p r o t e c t i v e c o v e r i n g o n s t a i n l e s s s t e e l l i d u n t i l i n s t a l l a- t i o n i s c o m p l e t e .

BOOST / CUT on the P500 is +/ – 18 dB . The rotary poten- t i o m e t e r p r o v i d e s c o n t i n u o u s l y v a r i a b l e a d j u s t m e n t .

P 5 0 0 T U N I N G S E Q U E N C E

T h e P 5 0 0 i s d e s i g n e d t o b e “ s e t - u p ” o r “ t u n e d ” w i t h t h e a i d of a R e a l T i m e S p e c t r u m A n a l y z e r m e a s u r i n g a p i n k n o i s e s i g- nal generated by t he m o b il e a u dio system . The analyzer pro- vides visual feedback when following the steps listed below .

R T A t h e s y s t e m a n d d e t e r m i n e p o i n t s o f a d j u s t m e n t . T u r n t h e s y s t e m o f f a n d p l a c e e a c h o f t h e f r e q u e n c y r a n g e j u m p e r s i n t o t h e i r c o r r e s p o n d i n g “ f r e q u e n c y r a n g e ” p o s i t i o n s .

TEMPORARILY MOUNT P500:

The P50 0 is desig n e d t o be an c hored through the four (4) h o l e s l o c a t e d o n t h e c i r c u i t b o a r d / b a s e a s s e m b l y .

MARK WIRES FOR TERMINATION AND REMOVE P500: Determine wire lengths for Power, Ground & Remote and m a r k f o r c u t t i n g / t e r m i n a t i o n . R e m o v e P 5 0 0 b e f o r e c u t- t i n g a n d t e r m i n a t i n g a l l w i r e s . C A U T I O N : s t r i p p i n g w i r e s o v e r t h e c i r c u i t b o a r d m a y c a u s e p r o d u c t f a i l u r e .

INPUT SENSITIVITY:

M a k e i n i t i a l a d j u s t m e n t t o i n p u t g a i n a t y o u r w o r k b e n c h . Refer to the section “Input Sensitivity” on the reverse s i d e .

P e r f o r m t h e f o l l o w i n g s t e p s p e r b a n d:

W i t h t h e s y s t e m p l a y i n g p i n k n o i s e , t u r n o n t h e RTA and adjust pink noise SPL to 85 – 90 dB .

Turn the boost/cut control to +18 dB (full clockwise rotation) . This will show the present center frequen- cy and “Q” settings on the analyzer.

Rotate frequency control to the frequency you wish to a d j u s t .

Adjust “Q” setting to match the width of the dip or peak you are addressing .

Finally, adjust the gain control to achieve the desired response curve .

| FREQ. RANGE | FREQ. RANGE | FREQ. RANGE | FREQ. RANGE | FREQ. RANGE |

| 20 – 200 HZ | 20 – 200 HZ | 20 – 200 HZ | 20 – 200 HZ | 20 – 200 HZ |

| 200 – 2 KHZ | 200 – 2 KHZ | 200 – 2 KHZ | 200 – 2 KHZ | 200 – 2 KHZ |

|

| 2K – 20 KHZ | 2K – 20 KHZ | 2K – 20 KHZ | 2K – 20 KHZ | 2K – 20 KHZ |

SYSTEM COMPONENTS

| | S O U R C E | | | | | S E R I A L # |

| | | | |

| | P R O C E S S O R( S ) | | | | S E R I A L # |

| | | | |

| | | | | S E R I A L # |

| | | | |

| | A M P L I F I E R( S ) | | | S E R I A L # |

| | | |

| | | | | S E R I A L # |

| | | | |

| | | | | S E R I A L # |

| | | | |

| | | | | | | |

| | | | | | | |

x t a n t t e c h n o l o g i e s | | | • | • | | • | • | • | • | • | • | • |

7 6 7 6 SO U T H 4 6T H STREET | PHOENIX, ARIZONA 8 5 0 4 0 U S A | | |

• | • | • | | • | • | • | | • | • 6 0 2 4 3 1 8 6 8 6 | |

BALANCED LINE:

Make initial adjustment at your work bench . Refer to the section “Balanced Line” on the reverse side

MOUNT THE P500 AND MAKE ALL CONNECTIONS:

Re - install the P50 0 an d ma ke all wire connections . i . e . Power, Ground, Remote and RCA i n p u t / o u t p u t s .

DOUBLE CHECK ALL CONNECTIONS! TURN ON P500:

C h e c k r e d LED, i t s h o u l d b e o n .

MAKE ALL EQUALIZATION ADJUSTMENTS:

Refer to “P500 Tuning Sequence” in this “Reference”

ADJUST NOISE GATE THRESHOLD (IF USED):

Refer to “Activating the Noise Gate” on the reverse side

AFTER FINE TUNING THE SYSTEM:

Remove protective covering from P500 and clean . A t t a c h cover to base .