The user should revise the inspection interval, add additional units or provide a similar form to suit particular conditions that may exist. However, written, dated and signed inspection reports should be maintained particularly on critical items such as hoist hooks, hoisting rope, sheaves, drums and brakes. Periodic review of old inspection reports can point out service life of hoist components, forecasting need for adjustment, repair or replacement of these components.

As a matter of expedience, appointed maintenance personnel inspecting hoist can also take care of minor adjustments, repairs and cleaning, where required. Note column on Inspection Schedule and Maintenance Report form headed Corrective Action and Notes. When corrective action is made during inspection, note condition of part or unit as inspected in appropriate Condition column with a check mark (`). Note “during inspection” corrective action taken and date in space provided. In this manner, items requiring further attention will be checked (`) without showing corrective action. This will advise the designated person responsible for hoist operation and safety, who reviews the reports that deficiencies exist. The designated person will check all deficiencies as listed and

![]() WARNING

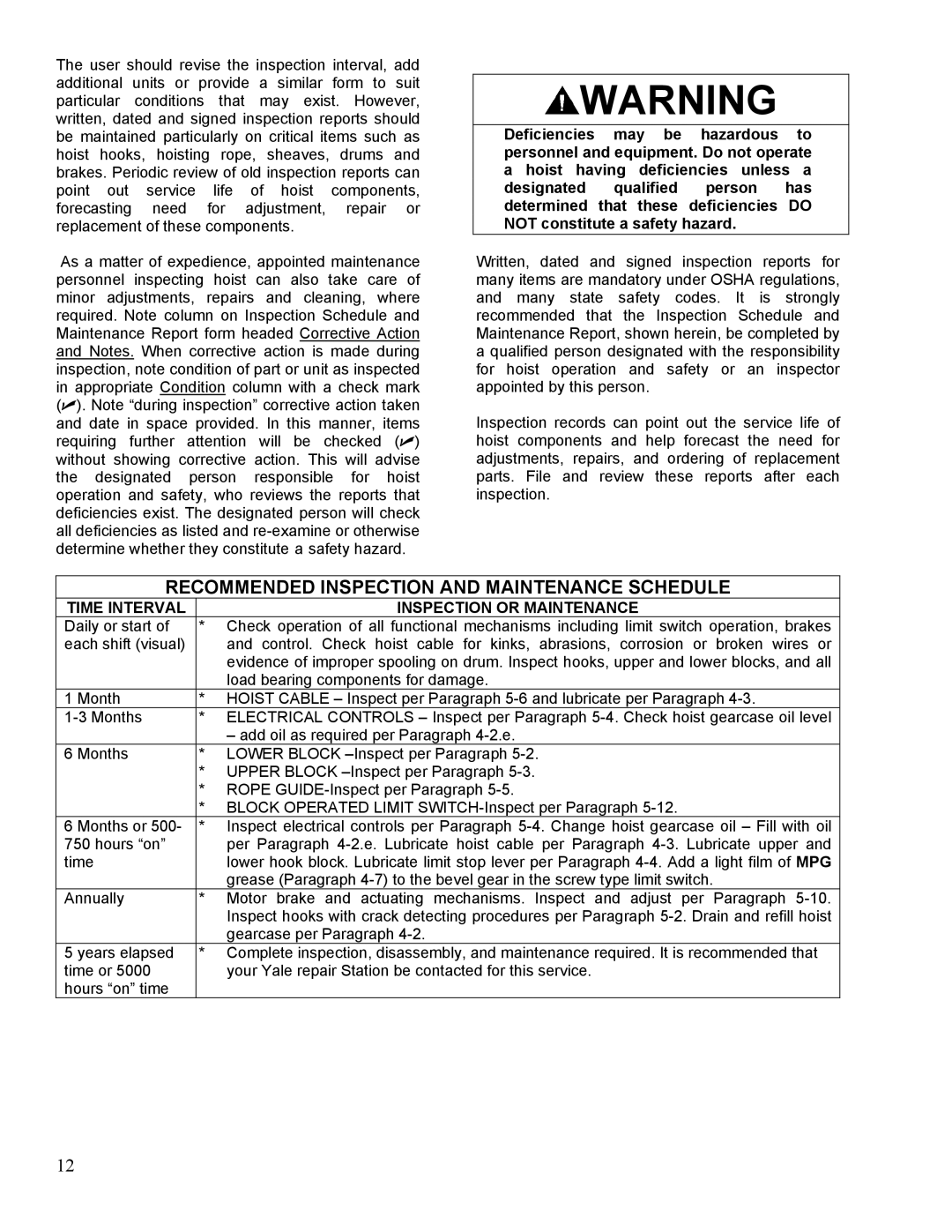

WARNING

Deficiencies may be hazardous to personnel and equipment. Do not operate a hoist having deficiencies unless a designated qualified person has determined that these deficiencies DO NOT constitute a safety hazard.

Written, dated and signed inspection reports for many items are mandatory under OSHA regulations, and many state safety codes. It is strongly recommended that the Inspection Schedule and Maintenance Report, shown herein, be completed by a qualified person designated with the responsibility for hoist operation and safety or an inspector appointed by this person.

Inspection records can point out the service life of hoist components and help forecast the need for adjustments, repairs, and ordering of replacement parts. File and review these reports after each inspection.

RECOMMENDED INSPECTION AND MAINTENANCE SCHEDULE

TIME INTERVAL | INSPECTION OR MAINTENANCE |

Daily or start of | * Check operation of all functional mechanisms including limit switch operation, brakes |

each shift (visual) | and control. Check hoist cable for kinks, abrasions, corrosion or broken wires or |

| evidence of improper spooling on drum. Inspect hooks, upper and lower blocks, and all |

| load bearing components for damage. |

1 Month | * HOIST CABLE – Inspect per Paragraph |

* ELECTRICAL CONTROLS – Inspect per Paragraph | |

| – add oil as required per Paragraph |

6 Months | * LOWER BLOCK |

| * UPPER BLOCK |

| * ROPE |

| * BLOCK OPERATED LIMIT |

6 Months or 500- | * Inspect electrical controls per Paragraph |

750 hours “on” | per Paragraph |

time | lower hook block. Lubricate limit stop lever per Paragraph |

| grease (Paragraph |

Annually | * Motor brake and actuating mechanisms. Inspect and adjust per Paragraph |

| Inspect hooks with crack detecting procedures per Paragraph |

| gearcase per Paragraph |

5 years elapsed | * Complete inspection, disassembly, and maintenance required. It is recommended that |

time or 5000 | your Yale repair Station be contacted for this service. |

hours “on” time |

|

12