MAINTENANCE

wire and ground against the engine WARNING: Disconnect the spark plug

before performing any adjustments, repairs or maintenance.

TROUBLE SHOOTING

Refer to the chart on page 17 for trouble shooting engine problems.

HYDROSTATICTRANSMISSION COOLING

The hydrostatic transmission is cooled by the oil, fan and fins. If the hydrostatic transmission runs hot,

check to see if the fan is in operating condition, the oil level is correct and the fins are clean.

NOTE: DO NOT use high pressure water spray or

steam to clean the hydrostatic transmission.

ENGINE

Refer to the separate engine manual for engine maintenance instructions,

Service air cleaner every 10 hours under normal conditions. Clean every few hours under extremely dusty conditions. To service the air cleaner, refer to the separate engine manual packed with your unit.

The spark plug(s) should be cleaned and the gap reset once a season. Spark plug replacement is recommended at the start of each mowing season; check engine manual for correct plug type and gap specifications.

Maintain engine oil as instructed in the separate engine manual packed with your unit. Read and follow instructions carefully.

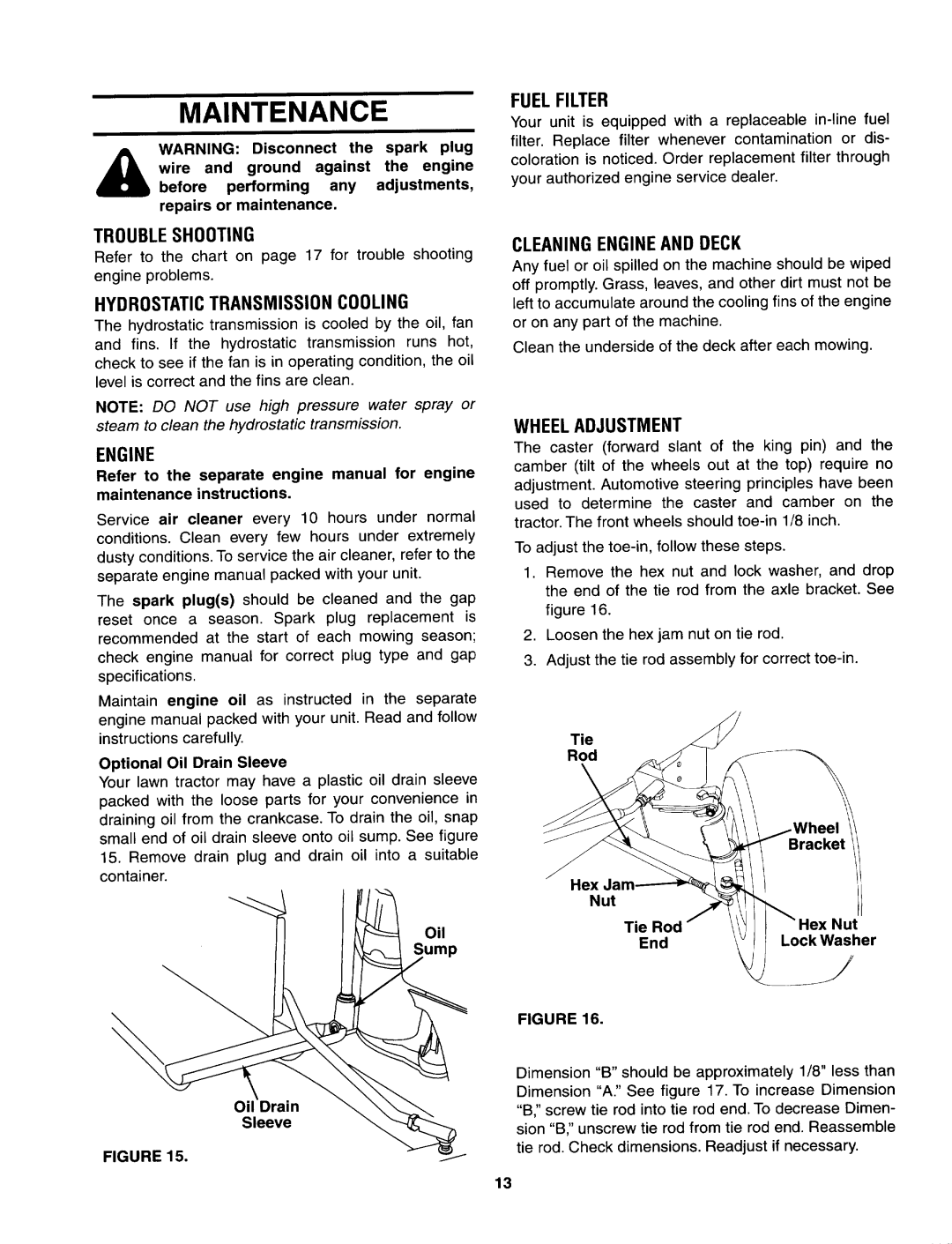

Optional Oil Drain Sleeve

Your lawn tractor may have a plastic oil drain sleeve packed with the loose parts for your convenience in draining oil from the crankcase. To drain the oil, snap small end of oil drain sleeve onto oil sump. See figure

15.Remove drain plug and drain oil into a suitable container.

Oil

,ump

FUELFILTER

Your unit is equipped with a replaceable

CLEANING ENGINE AND DECK

Any fuel or oil spilled on the machine should be wiped off promptly. Grass, leaves, and other dirt must not be left to accumulate around the cooling fins of the engine or on any part of the machine.

Clean the underside of the deck after each mowing.

WHEEL ADJUSTMENT

The caster (forward slant of the king pin) and the camber (tilt of the wheels out at the top) require no

adjustment. Automotive steering principles have been used to determine the caster and camber on the

tractor. The front wheels should

To adjust the

1.Remove the hex nut and lock washer, and drop the end of the tie rod from the axle bracket. See figure 16.

2.Loosen the hex jam nut on tie rod.

3.Adjust the tie rod assembly for correct

Tie

Rod

\

| "ac'ei |

Hex Jam, |

|

Nut |

|

Tie Rod | Hex Nut |

End | Lock Washer |

| / |

FIGURE 16. |

|

Oil Drain

Sleeve

FIGURE 15.

Dimension "B" should be approximately 1/8" less than Dimension "A." See figure 17. To increase Dimension "B," screw tie rod into tie rod end. To decrease Dimen- sion "B," unscrew tie rod from tie rod end. Reassemble tie rod. Check dimensions. Readjust if necessary.

13