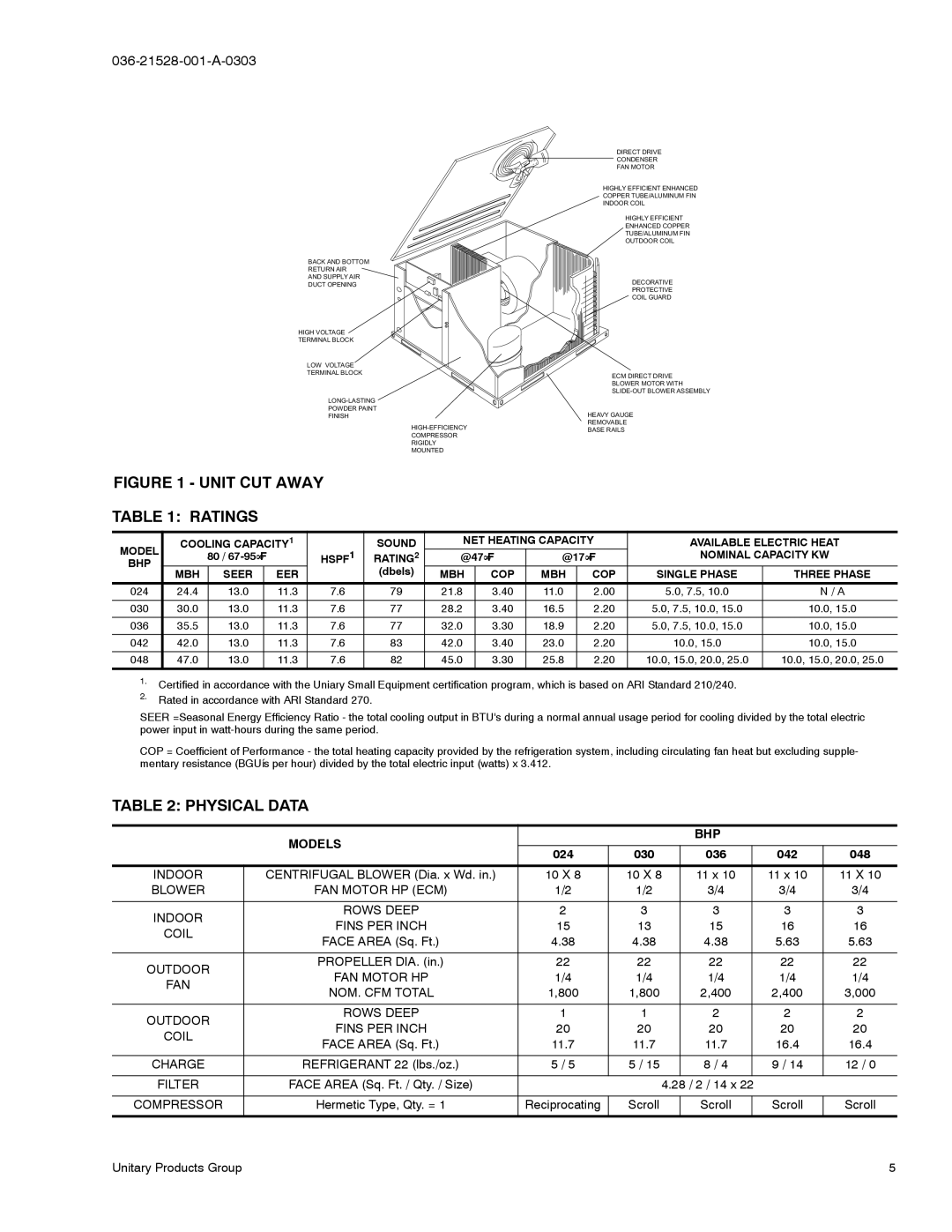

B1HP024 THRU 048 specifications

The York B1HP024 THRU 048 is a line of high-efficiency ducted split-system air conditioning units, designed to deliver optimal performance for residential and commercial spaces. These models are known for their advanced engineering and effective cooling capabilities, making them a popular choice among HVAC professionals.One of the standout features of the York B1HP024 THRU 048 series is its energy efficiency. With SEER (Seasonal Energy Efficiency Ratio) ratings that exceed industry standards, these units help reduce energy consumption and lower utility bills. This efficiency is achieved through the use of modern compressor technology and an intelligent control system that adjusts cooling output based on real-time demand.

Another key characteristic of the York B1HP024 THRU 048 series is its use of inverter-driven compressors. This technology allows the units to adjust their speed dynamically, providing precise cooling without the frequent on-off cycling typical of traditional systems. As a result, users experience a quieter operation and improved comfort levels in their living or working spaces.

The design of these units emphasizes ease of installation and maintenance. The compact form factor and lightweight construction facilitate a smoother installation process, while service-friendly components make routine maintenance straightforward. This is particularly beneficial for technicians, as it reduces downtime and improves the reliability of the system.

In terms of comfort features, the York B1HP024 THRU 048 line is equipped with advanced filtration systems that enhance indoor air quality. These filters capture dust, allergens, and other airborne particles, creating a healthier environment for occupants. Additionally, some models come with smart technology integration, allowing users to control their HVAC system remotely via smartphones or smart home systems.

Durability is another hallmark of the York B1HP024 THRU 048 series. Constructed with high-quality materials and components that resist wear and tear, these units are built to last. Furthermore, they are designed to operate effectively in various environmental conditions, ensuring reliable performance year-round.

In summary, the York B1HP024 THRU 048 units combine energy efficiency, advanced technology, user-friendly design, and durability, making them an excellent choice for those seeking reliable cooling solutions. Whether for home or business, these systems provide not only comfort but also peace of mind.