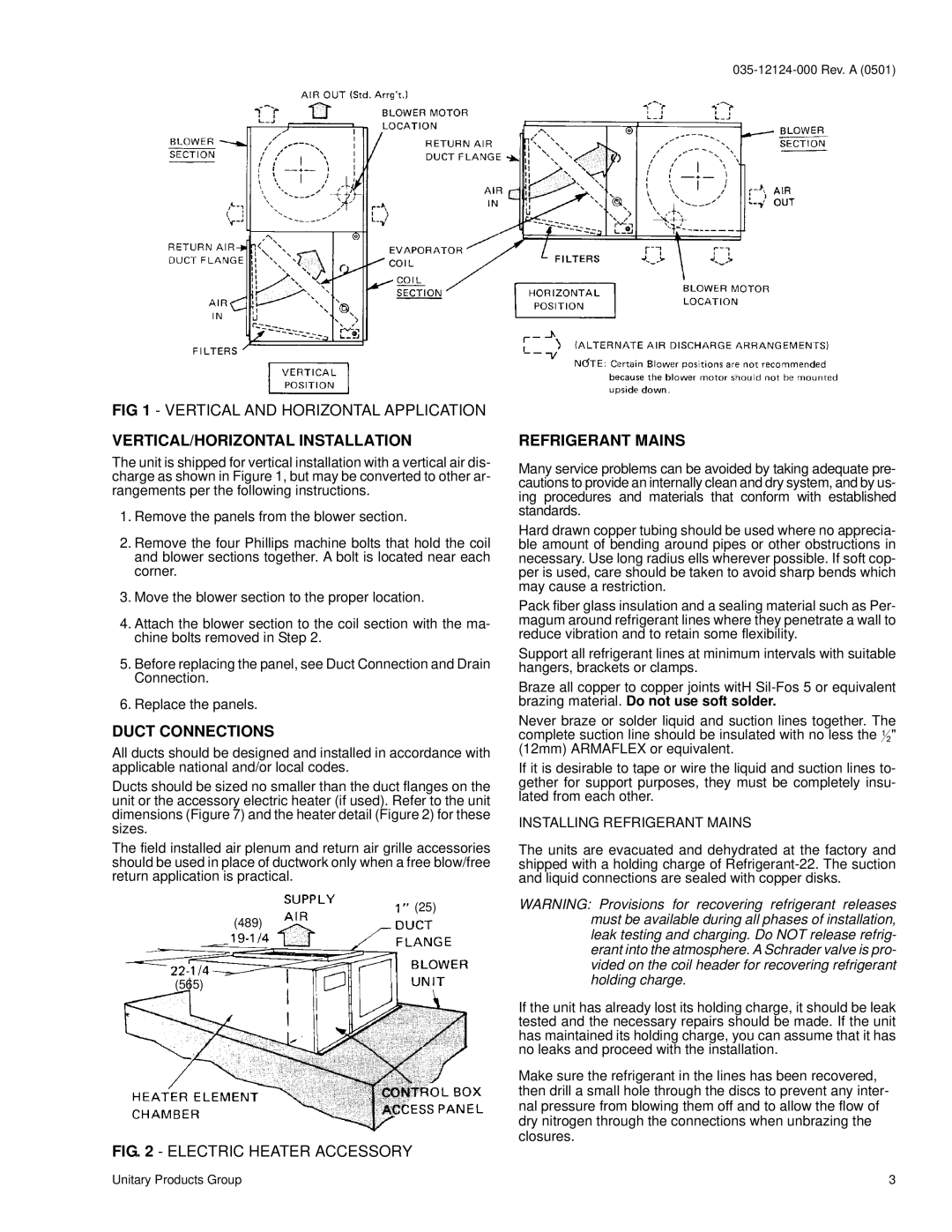

FIG 1 - VERTICAL AND HORIZONTAL APPLICATION

VERTICAL/HORIZONTAL INSTALLATION

The unit is shipped for vertical installation with a vertical air dis- charge as shown in Figure 1, but may be converted to other ar- rangements per the following instructions.

1.Remove the panels from the blower section.

2.Remove the four Phillips machine bolts that hold the coil and blower sections together. A bolt is located near each corner.

3.Move the blower section to the proper location.

4.Attach the blower section to the coil section with the ma- chine bolts removed in Step 2.

5.Before replacing the panel, see Duct Connection and Drain Connection.

6.Replace the panels.

DUCT CONNECTIONS

All ducts should be designed and installed in accordance with applicable national and/or local codes.

Ducts should be sized no smaller than the duct flanges on the unit or the accessory electric heater (if used). Refer to the unit dimensions (Figure 7) and the heater detail (Figure 2) for these sizes.

The field installed air plenum and return air grille accessories should be used in place of ductwork only when a free blow/free return application is practical.

(25)

(489)

(565)

FIG. 2 - ELECTRIC HEATER ACCESSORY

REFRIGERANT MAINS

Many service problems can be avoided by taking adequate pre- cautions to provide an internally clean and dry system, and by us- ing procedures and materials that conform with established standards.

Hard drawn copper tubing should be used where no apprecia- ble amount of bending around pipes or other obstructions in necessary. Use long radius ells wherever possible. If soft cop- per is used, care should be taken to avoid sharp bends which may cause a restriction.

Pack fiber glass insulation and a sealing material such as Per- magum around refrigerant lines where they penetrate a wall to reduce vibration and to retain some flexibility.

Support all refrigerant lines at minimum intervals with suitable hangers, brackets or clamps.

Braze all copper to copper joints witH

Never braze or solder liquid and suction lines together. The complete suction line should be insulated with no less the ![]() 12" (12mm) ARMAFLEX or equivalent.

12" (12mm) ARMAFLEX or equivalent.

If it is desirable to tape or wire the liquid and suction lines to- gether for support purposes, they must be completely insu- lated from each other.

INSTALLING REFRIGERANT MAINS

The units are evacuated and dehydrated at the factory and shipped with a holding charge of

WARNING: Provisions for recovering refrigerant releases must be available during all phases of installation, leak testing and charging. Do NOT release refrig- erant into the atmosphere. A Schrader valve is pro- vided on the coil header for recovering refrigerant holding charge.

If the unit has already lost its holding charge, it should be leak tested and the necessary repairs should be made. If the unit has maintained its holding charge, you can assume that it has no leaks and proceed with the installation.

Make sure the refrigerant in the lines has been recovered, then drill a small hole through the discs to prevent any inter- nal pressure from blowing them off and to allow the flow of dry nitrogen through the connections when unbrazing the closures.

Unitary Products Group | 3 |