FORM

INSTALLATION

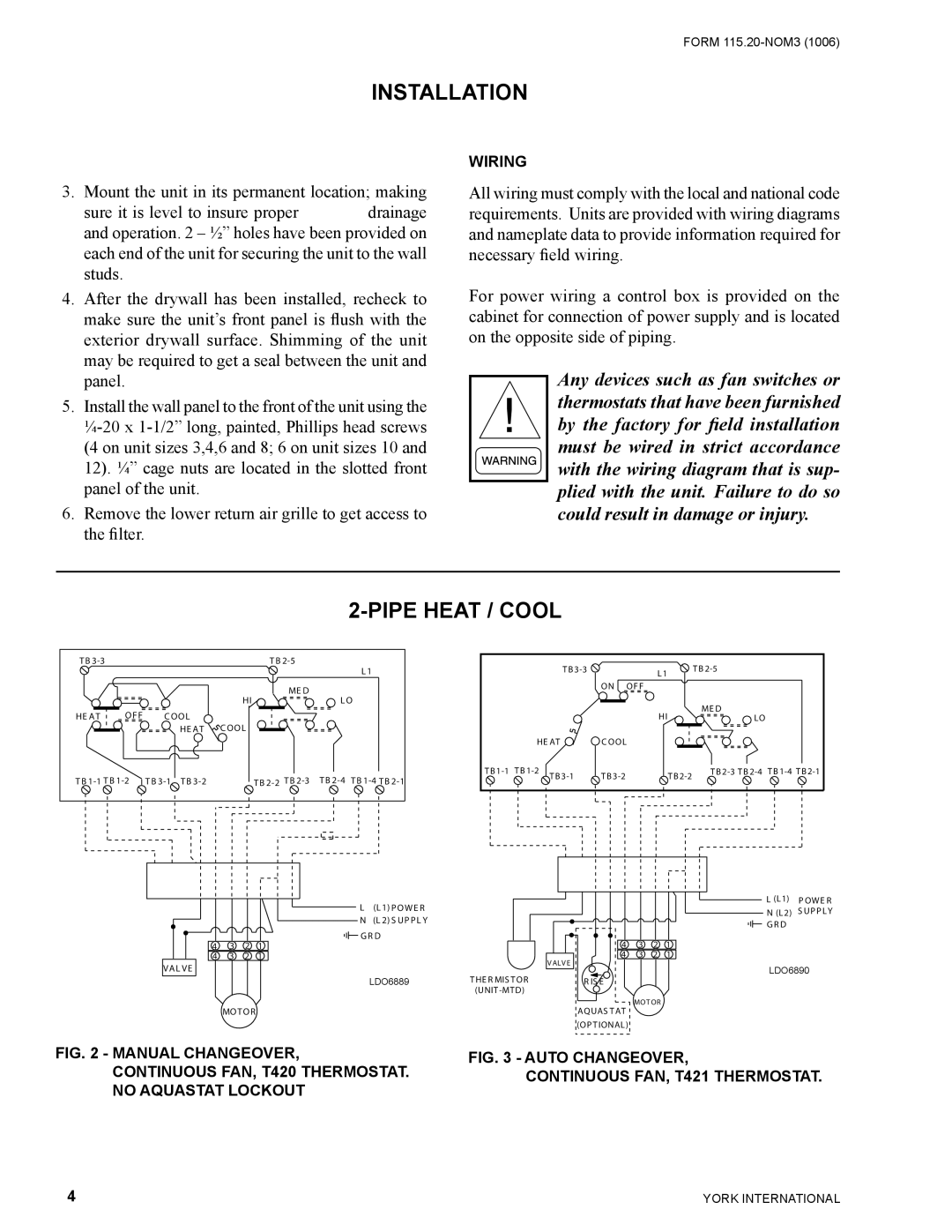

WIRING

3. Mount the unit in its permanent location; making

sure it is level to insure proper drainage and operation. 2 – ½” holes have been provided on each end of the unit for securing the unit to the wall studs.

4.After the drywall has been installed, recheck to make sure the unit’s front panel is flush with the exterior drywall surface. Shimming of the unit may be required to get a seal between the unit and panel.

5.Install the wall panel to the front of the unit using the

6.Remove the lower return air grille to get access to the filter.

All wiring must comply with the local and national code requirements. Units are provided with wiring diagrams and nameplate data to provide information required for necessary field wiring.

For power wiring a control box is provided on the cabinet for connection of power supply and is located on the opposite side of piping.

Any devices such as fan switches or thermostats that have been furnished by the factory for field installation must be wired in strict accordance with the wiring diagram that is sup- plied with the unit. Failure to do so could result in damage or injury.

2-PIPE HEAT / COOL

TB |

|

|

| TB |

|

|

|

| L 1 |

|

|

|

| ME D |

|

|

| HI | L O |

HE AT | OF F | C OOL |

|

|

|

| HE AT | C OOL |

|

TB | TB |

| TB | |

|

|

| L1 |

|

| ||

|

|

|

|

|

|

| |

|

|

| ON | OF F |

|

|

|

|

|

|

| HI |

| ME D |

|

|

|

|

|

| LO |

| |

| HE AT | C OOL |

|

|

|

| |

| |||||||

|

|

|

|

| |||

|

|

| L (L 1) P OWE R |

|

|

| N (L 2) S UP P L Y |

| 3 | 2 | GR D |

4 | 1 | ||

4 | 3 | 2 | 1 |

VAL VE |

|

|

|

|

|

| LDO6889 |

| MOTOR |

| |

THE R MIS TOR (UNIT

VALVE

4 | 3 | 2 | 1 |

4 | 3 | 2 | 1 |

R IS E |

|

|

|

| MOTOR |

| |

AQUAS TAT |

|

|

|

(OPTIONAL)

L (L1) | POWE R |

N (L2) | S UPPLY |

GR D |

|

LDO6890

FIG. 2 - MANUAL CHANGEOVER, CONTINUOUS FAN, T420 THERMOSTAT. NO AQUASTAT LOCKOUT

FIG. 3 - AUTO CHANGEOVER, CONTINUOUS FAN, T421 THERMOSTAT.

4 | YORK INTERNATIONAL |