FORM

INSTALLATION

4-PIPE HEAT / COOL

|

|

|

|

| |||

|

|

|

| HI | ME D | LO |

|

|

|

|

|

|

| ||

HE AT | OF F | C OOL |

|

|

|

| |

|

|

| HE AT | C OOL |

|

|

|

|

|

| L1 |

|

| ||

|

|

| ON |

|

|

| |

|

|

| OF F |

|

|

| |

|

|

|

|

|

| ME D |

|

|

|

|

| HI |

| LO |

|

| HE AT | C OOL |

|

|

|

| |

| |||||||

|

|

|

|

| |||

THE R MIS TOR (UNIT

| 4 | 3 | 2 | 1 |

H | 4 | 3 | 2 | 1 |

C |

|

|

|

VALVE S

MOTOR

L(L1) P OWE R N (L2) S UP P LY

![]()

![]()

![]() GR D

GR D

LDO6891

| 4 | 3 | 2 | 1 |

H | 4 | 3 | 2 | 1 |

C |

|

|

|

VALVE S

MOTOR

L(L1) P OWE R N (L2) S UP P LY

![]()

![]()

![]() GR D

GR D

LDO6892

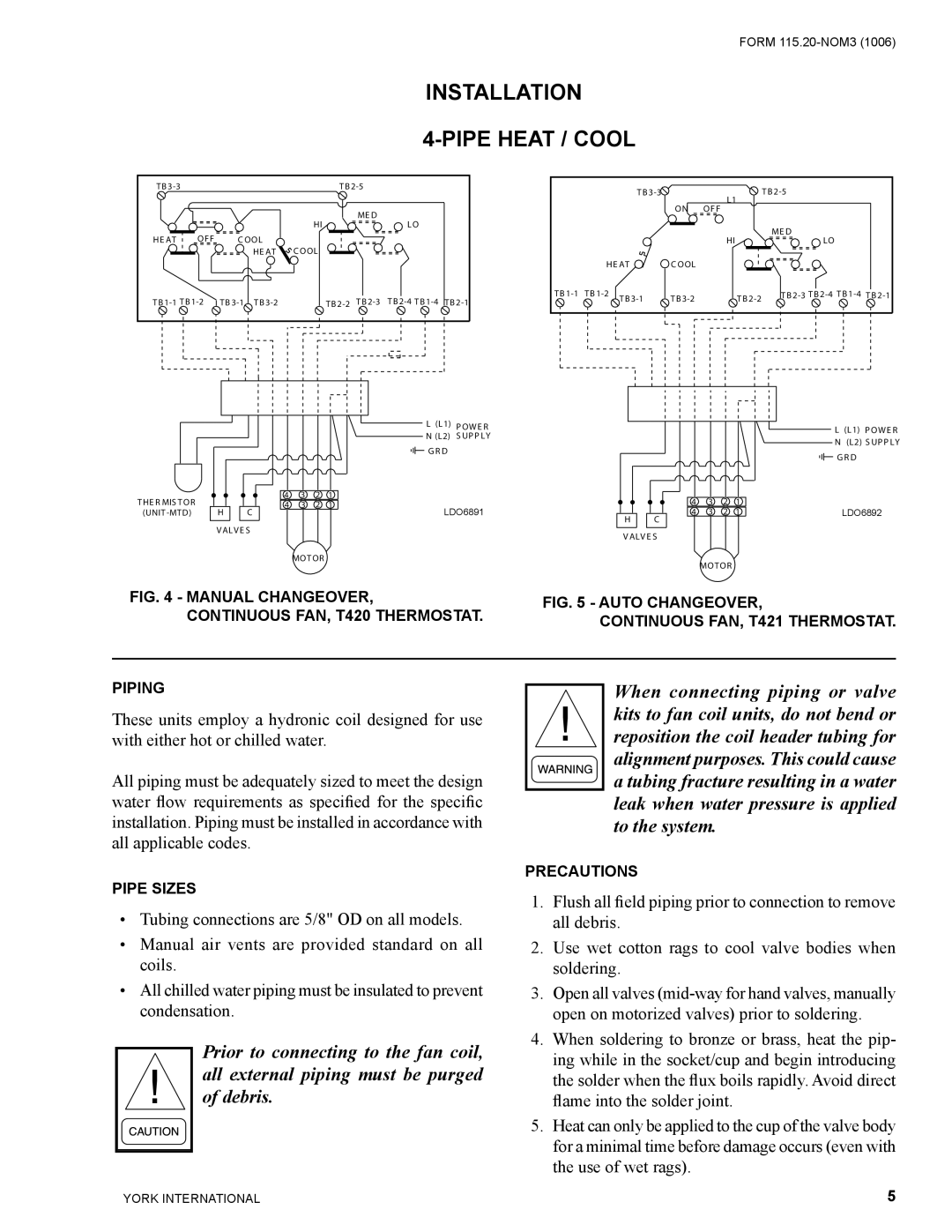

FIG. 4 - MANUAL CHANGEOVER, | FIG. 5 - AUTO CHANGEOVER, | |

CONTINUOUS FAN, T420 THERMOSTAT. | ||

CONTINUOUS FAN, T421 THERMOSTAT. | ||

|

PIPING

These units employ a hydronic coil designed for use with either hot or chilled water.

All piping must be adequately sized to meet the design water flow requirements as specified for the specific installation. Piping must be installed in accordance with all applicable codes.

PIPE SIZES

•Tubing connections are 5/8" OD on all models.

•Manual air vents are provided standard on all coils.

•All chilled water piping must be insulated to prevent condensation.

Prior to connecting to the fan coil, all external piping must be purged of debris.

When connecting piping or valve kits to fan coil units, do not bend or reposition the coil header tubing for alignment purposes. This could cause a tubing fracture resulting in a water leak when water pressure is applied to the system.

PRECAUTIONS

1.Flush all field piping prior to connection to remove all debris.

2.Use wet cotton rags to cool valve bodies when soldering.

3.Open all valves

4.When soldering to bronze or brass, heat the pip- ing while in the socket/cup and begin introducing the solder when the flux boils rapidly. Avoid direct flame into the solder joint.

5.Heat can only be applied to the cup of the valve body for a minimal time before damage occurs (even with the use of wet rags).

YORK INTERNATIONAL | 5 |