cleaning, but do not let it hang closer than 50mm (2") to the floor. The cable can be looped if necessary, but make sure that it is not twisted or trapped when the cooker is in position.

1![]()

L

![]() 2

2

![]()

![]() 3

3 ![]()

![]() 4

4

N | 5 |

TAB. D |

| GENERAL INJECTORS TABLE |

| |||

Kind of gas | mbar | Nozzle | Burners | Power Watt | Consum. | |

|

| N. | max. | min. | max. | |

|

| 1.15 | 3000 | 750 | 286 l/h | |

NATURAL | 20 | 0.97 | 1750 | 480 | 167 l/h | |

|

| 0.72 | 1000 | 330 | 95 l/h | |

|

| 1.28 | 3300 | 1300 | 315 l/h | |

|

|

|

|

|

|

|

G.P.L. | 30 | 0.85 | 3000 | 750 | 219 g/h | |

BUTANE | 28 | 0.65 | 1750 | 480 | 128 g/h | |

PROPANE | 37 | 0.50 | 1000 | 330 | 73 g/h | |

|

| 0.93 | 3300 | 1300 | 241 g/h | |

|

|

|

|

|

|

|

A

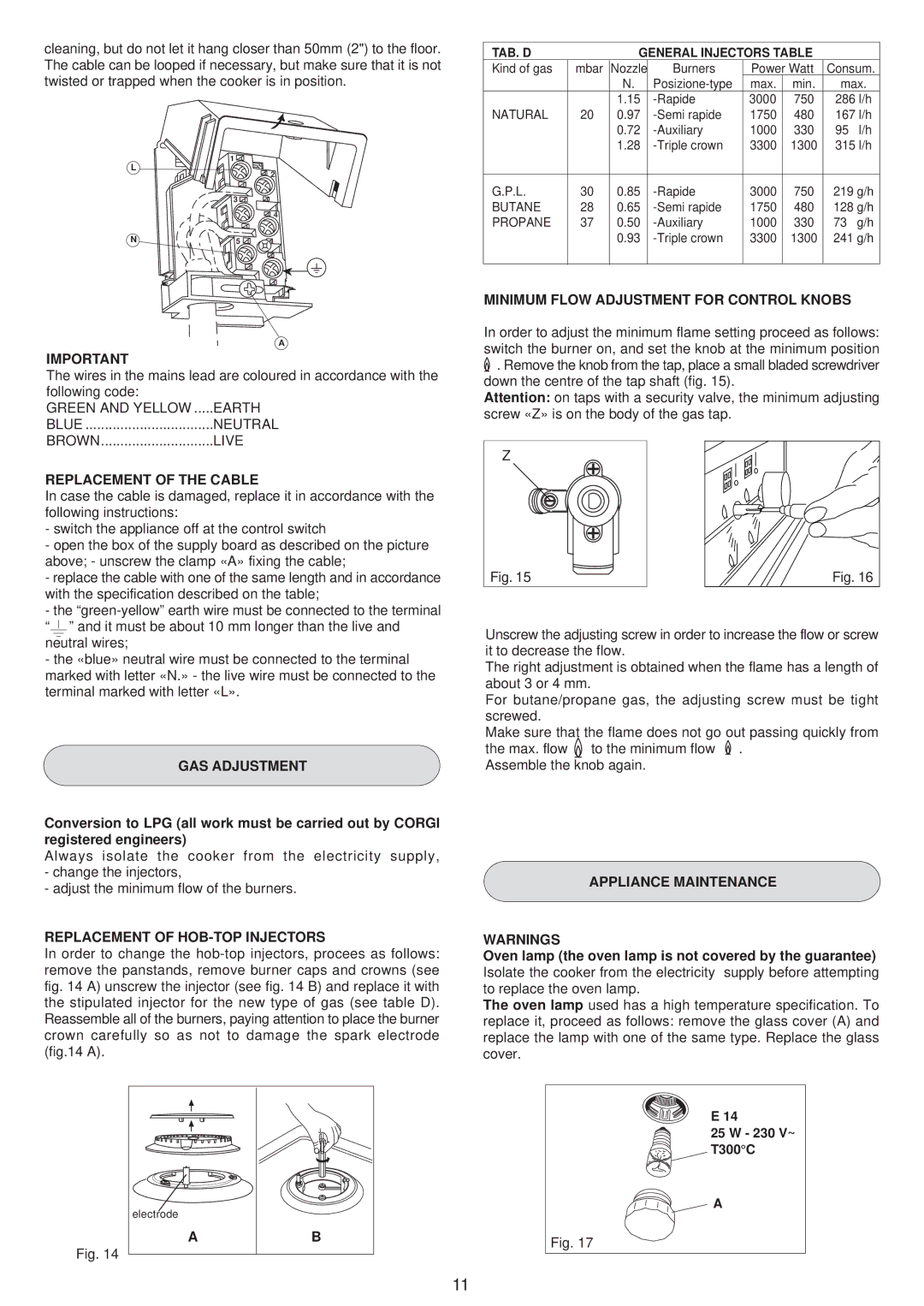

IMPORTANT

The wires in the mains lead are coloured in accordance with the

following code: |

|

GREEN AND YELLOW | .....EARTH |

BLUE | NEUTRAL |

BROWN | LIVE |

REPLACEMENT OF THE CABLE

In case the cable is damaged, replace it in accordance with the following instructions:

-switch the appliance off at the control switch

-open the box of the supply board as described on the picture above; - unscrew the clamp «A» fixing the cable;

-replace the cable with one of the same length and in accordance with the specification described on the table;

-the ![]() ” and it must be about 10 mm longer than the live and neutral wires;

” and it must be about 10 mm longer than the live and neutral wires;

-the «blue» neutral wire must be connected to the terminal marked with letter «N.» - the live wire must be connected to the terminal marked with letter «L».

GAS ADJUSTMENT

MINIMUM FLOW ADJUSTMENT FOR CONTROL KNOBS

In order to adjust the minimum flame setting proceed as follows: switch the burner on, and set the knob at the minimum position ![]() . Remove the knob from the tap, place a small bladed screwdriver down the centre of the tap shaft (fig. 15).

. Remove the knob from the tap, place a small bladed screwdriver down the centre of the tap shaft (fig. 15).

Attention: on taps with a security valve, the minimum adjusting screw «Z» is on the body of the gas tap.

Z |

|

Fig. 15 | Fig. 16 |

Unscrew the adjusting screw in order to increase the flow or screw it to decrease the flow.

The right adjustment is obtained when the flame has a length of about 3 or 4 mm.

For butane/propane gas, the adjusting screw must be tight screwed.

Make sure that the flame does not go out passing quickly from the max. flow ![]() to the minimum flow

to the minimum flow ![]() .

.

Assemble the knob again.

Conversion to LPG (all work must be carried out by CORGI registered engineers)

Always isolate the cooker from the electricity supply,

-change the injectors,

-adjust the minimum flow of the burners.

REPLACEMENT OF HOB-TOP INJECTORS

In order to change the

electrode |

|

A | B |

Fig. 14 |

|

APPLIANCE MAINTENANCE

WARNINGS

Oven lamp (the oven lamp is not covered by the guarantee)

Isolate the cooker from the electricity supply before attempting to replace the oven lamp.

The oven lamp used has a high temperature specification. To replace it, proceed as follows: remove the glass cover (A) and replace the lamp with one of the same type. Replace the glass cover.

E 14

25 W - 230 V~ T300°C

A

Fig. 17

11