various parts during assembly.

5.On relieving 15R units, gently and firmly press vent seal into piston using a blunt instrument.

6.Install lip seal onto piston with the lips of the seal facing away from the support flange. Then insert control spring and piston assembly into bonnet.

7.On 15R units, place balancing

8.On 15R units, tighten seat from 0.6 to 0.8 Nm (5 to 7

9.Make sure that the control spring is still uncompressed before turning on the air supply Turn on air supply, then slowly adjust the knob clockwise to increase downstream pressure until the desired pressure has been reached.

10.To decrease regulator pressure setting, always reset from a pressure lower than the final setting desired. For example, lowering the secondary pressure from 550 to 410 kPa (80 to 60 psig) is best accomplished by dropping the secondary pressure to 350 kPa (50 psig), then adjusting upward to 410 kPa (60 psig).

11.When the desired secondary pressure setting has been reached, push the adjusting knob down to lock it.

12.Check for leaks. If leaks occur, shut off the air supply, exhaust system air pressure, and make necessary adjustments to eliminate leakage.

Servicing Filter Element:

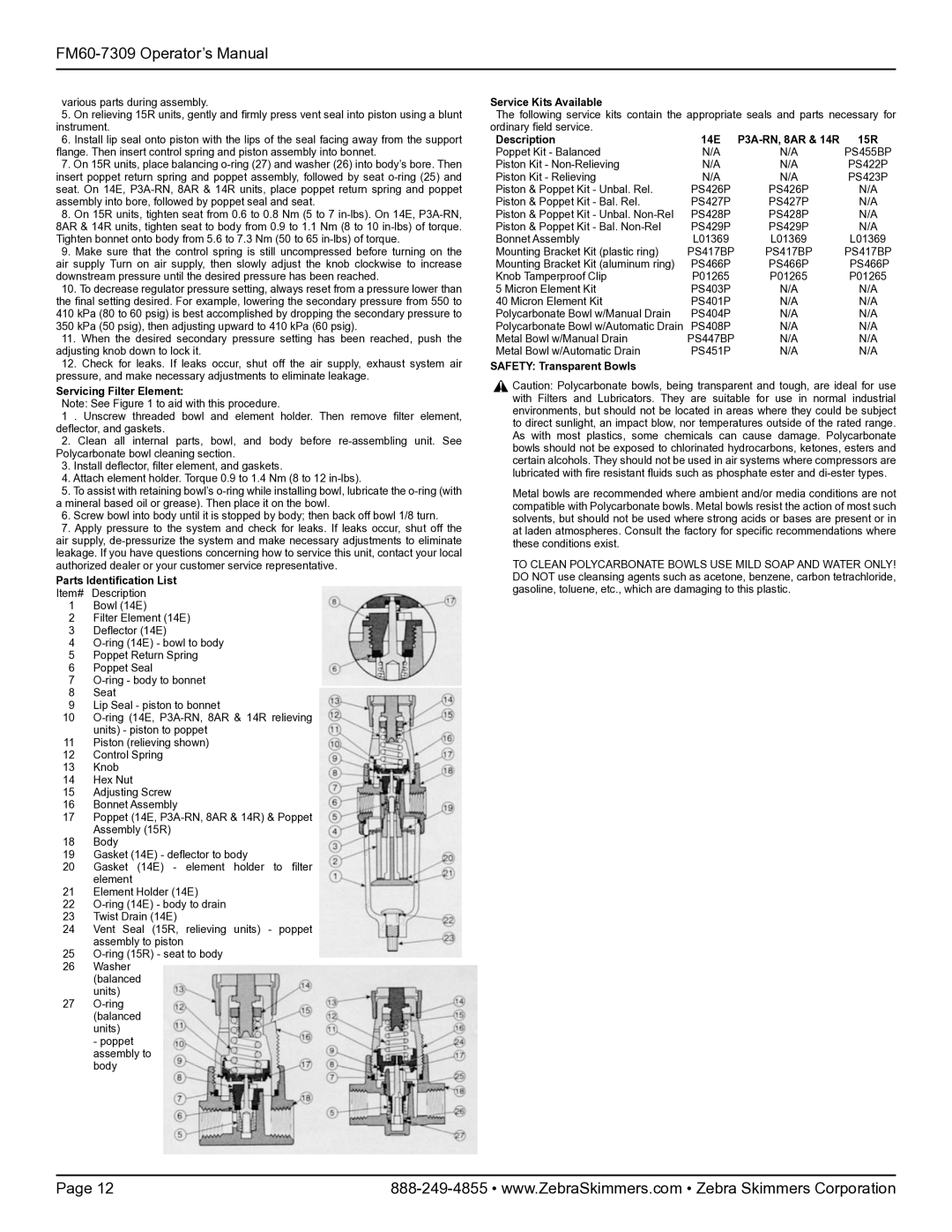

Note: See Figure 1 to aid with this procedure.

1 . Unscrew threaded bowl and element holder. Then remove filter element, deflector, and gaskets.

2.Clean all internal parts, bowl, and body before

3.Install deflector, filter element, and gaskets.

4.Attach element holder. Torque 0.9 to 1.4 Nm (8 to 12

5.To assist with retaining bowl’s

6.Screw bowl into body until it is stopped by body; then back off bowl 1/8 turn.

7.Apply pressure to the system and check for leaks. If leaks occur, shut off the air supply,

Parts Identification List

Item# Description

1Bowl (14E)

2Filter Element (14E)

3 Deflector (14E)

4

5 Poppet Return Spring

6 Poppet Seal

7

8Seat

9Lip Seal - piston to bonnet

10

11Piston (relieving shown)

12Control Spring

13Knob

14Hex Nut

15Adjusting Screw

16Bonnet Assembly

17Poppet (14E,

18Body

19Gasket (14E) - deflector to body

20Gasket (14E) - element holder to filter element

21Element Holder (14E)

22

23Twist Drain (14E)

24Vent Seal (15R, relieving units) - poppet assembly to piston

25

26Washer (balanced units)

27

- poppet

assembly to body

Service Kits Available

The following service kits contain the appropriate seals and parts necessary for

ordinary field service. |

|

|

|

|

Description | 14E |

| 15R | |

Poppet Kit - Balanced | N/A |

| N/A | PS455BP |

Piston Kit - | N/A |

| N/A | PS422P |

Piston Kit - Relieving | N/A |

| N/A | PS423P |

Piston & Poppet Kit - Unbal. Rel. | PS426P | PS426P | N/A | |

Piston & Poppet Kit - Bal. Rel. | PS427P | PS427P | N/A | |

Piston & Poppet Kit - Unbal. | PS428P | PS428P | N/A | |

Piston & Poppet Kit - Bal. | PS429P | PS429P | N/A | |

Bonnet Assembly | L01369 |

| L01369 | L01369 |

Mounting Bracket Kit (plastic ring) | PS417BP | PS417BP | PS417BP | |

Mounting Bracket Kit (aluminum ring) | PS466P | PS466P | PS466P | |

Knob Tamperproof Clip | P01265 |

| P01265 | P01265 |

5 Micron Element Kit | PS403P | N/A | N/A | |

40 Micron Element Kit | PS401P | N/A | N/A | |

Polycarbonate Bowl w/Manual Drain | PS404P | N/A | N/A | |

Polycarbonate Bowl w/Automatic Drain | PS408P | N/A | N/A | |

Metal Bowl w/Manual Drain | PS447BP | N/A | N/A | |

Metal Bowl w/Automatic Drain | PS451P | N/A | N/A | |

SAFETY: Transparent Bowls

![]() Caution: Polycarbonate bowls, being transparent and tough, are ideal for use with Filters and Lubricators. They are suitable for use in normal industrial environments, but should not be located in areas where they could be subject to direct sunlight, an impact blow, nor temperatures outside of the rated range. As with most plastics, some chemicals can cause damage. Polycarbonate bowls should not be exposed to chlorinated hydrocarbons, ketones, esters and certain alcohols. They should not be used in air systems where compressors are lubricated with fire resistant fluids such as phosphate ester and

Caution: Polycarbonate bowls, being transparent and tough, are ideal for use with Filters and Lubricators. They are suitable for use in normal industrial environments, but should not be located in areas where they could be subject to direct sunlight, an impact blow, nor temperatures outside of the rated range. As with most plastics, some chemicals can cause damage. Polycarbonate bowls should not be exposed to chlorinated hydrocarbons, ketones, esters and certain alcohols. They should not be used in air systems where compressors are lubricated with fire resistant fluids such as phosphate ester and

Metal bowls are recommended where ambient and/or media conditions are not compatible with Polycarbonate bowls. Metal bowls resist the action of most such solvents, but should not be used where strong acids or bases are present or in at laden atmospheres. Consult the factory for specific recommendations where these conditions exist.

TO CLEAN POLYCARBONATE BOWLS USE MILD SOAP AND WATER ONLY! DO NOT use cleansing agents such as acetone, benzene, carbon tetrachloride, gasoline, toluene, etc., which are damaging to this plastic.

Page 12 |