Pressure Regulator and Lubricator Package

Use the adjustment knob of the pressure regulator to adjust the air pressure going through the pump. It must be pulled up before adjusting.

Check the oil atomizer, lo- cated near the air line and behind the regulator, to verify that it is running at approxi- mately one drop every

(mineral) Oil when necessary. Use of the wrong oil may cause

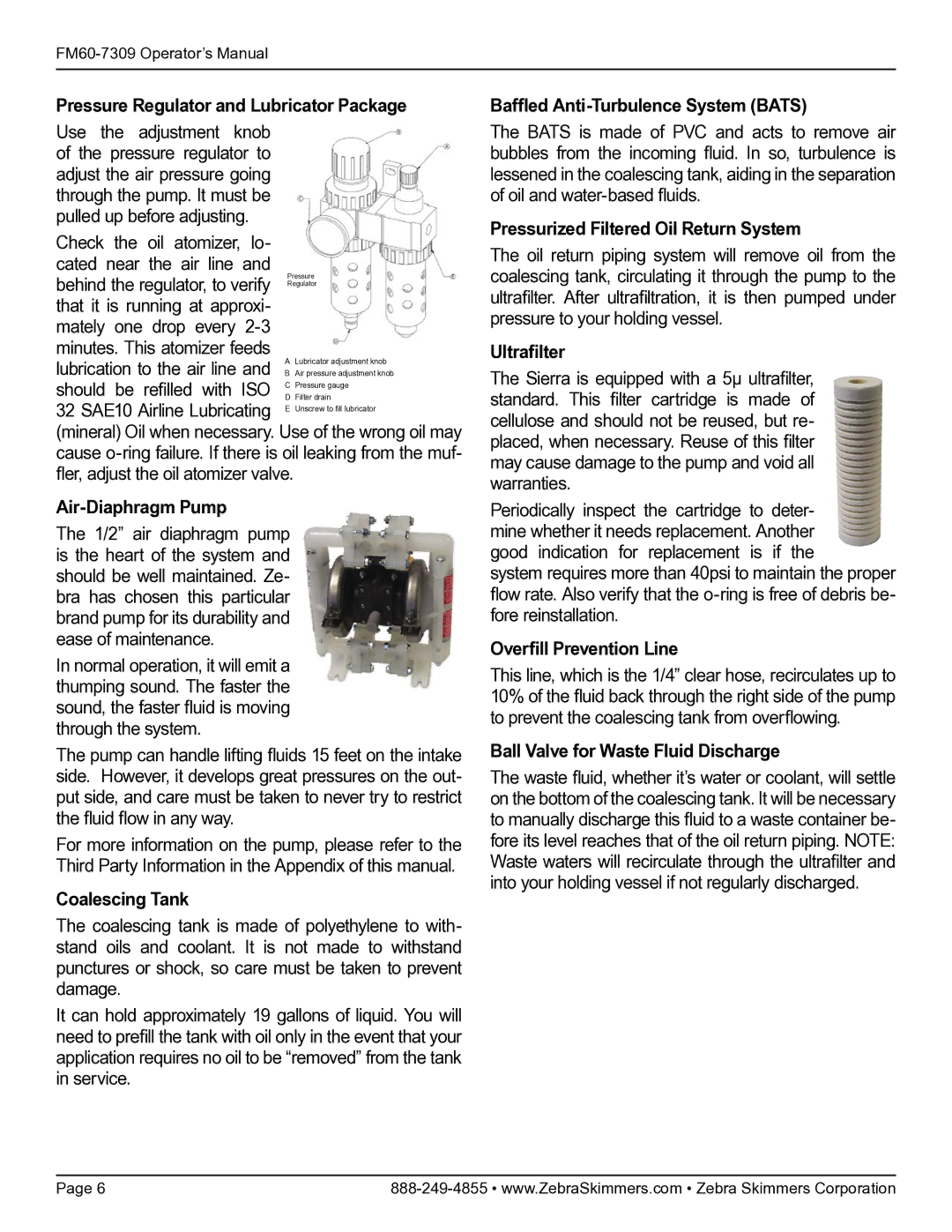

Air-Diaphragm Pump

The 1/2” air diaphragm pump is the heart of the system and should be well maintained. Ze- bra has chosen this particular brand pump for its durability and ease of maintenance.

In normal operation, it will emit a thumping sound. The faster the sound, the faster fluid is moving through the system.

The pump can handle lifting fluids 15 feet on the intake side. However, it develops great pressures on the out- put side, and care must be taken to never try to restrict the fluid flow in any way.

For more information on the pump, please refer to the Third Party Information in the Appendix of this manual.

Coalescing Tank

The coalescing tank is made of polyethylene to with- stand oils and coolant. It is not made to withstand punctures or shock, so care must be taken to prevent damage.

It can hold approximately 19 gallons of liquid. You will need to prefill the tank with oil only in the event that your application requires no oil to be “removed” from the tank in service.

Baffled Anti-Turbulence System (BATS)

The BATS is made of PVC and acts to remove air bubbles from the incoming fluid. In so, turbulence is lessened in the coalescing tank, aiding in the separation of oil and

Pressurized Filtered Oil Return System

The oil return piping system will remove oil from the coalescing tank, circulating it through the pump to the ultrafilter. After ultrafiltration, it is then pumped under pressure to your holding vessel.

Ultrafilter

The Sierra is equipped with a 5µ ultrafilter, standard. This filter cartridge is made of cellulose and should not be reused, but re- placed, when necessary. Reuse of this filter may cause damage to the pump and void all warranties.

Periodically inspect the cartridge to deter- mine whether it needs replacement. Another good indication for replacement is if the

system requires more than 40psi to maintain the proper flow rate. Also verify that the

Overfill Prevention Line

This line, which is the 1/4” clear hose, recirculates up to 10% of the fluid back through the right side of the pump to prevent the coalescing tank from overflowing.

Ball Valve for Waste Fluid Discharge

The waste fluid, whether it’s water or coolant, will settle on the bottom of the coalescing tank. It will be necessary to manually discharge this fluid to a waste container be- fore its level reaches that of the oil return piping. NOTE: Waste waters will recirculate through the ultrafilter and into your holding vessel if not regularly discharged.

Page 6 |