An Introduction To

Plastic Card Printing

Plastic cards have become part of everyone’s life, from credit cards to driver’s licences, membership cards to ID badges. Their size, portability and durability have made them the vehicle of choice for many applications.

Plastic card printers offer the ability to quickly and easily produce a custom card tailored to an application or to personalise a preprinted card on demand, at the point of issue. They are simple to integrate with image capture systems (digital cameras, scanners etc.) and most databases.

Digitally printed plastic cards start with a blank plastic card that can be printed with any combination of graphics, text, photo- graphs and barcodes. Additional electronic information can also be encoded, such as magnetic stripes and Smart Card chips.

How It Works

All plastic card printers feature the same basic printing operations; dye sublimation and/or thermal transfer

printing. Both techniques involve a ribbon being heated as it passes under a thermal print head. Thermal

transfer heats and transfers ink onto the plastic card surface

whereas dye sublimation heats and undergoes a chemical change process that

turns the ink into a gaseous state which then “dyes” the plastic card.

The ribbon used in colour dye sublimation printing is divided into separate colour panels; Yellow, Magenta, and Cyan. These are most

commonly seen as part of a ribbon referred to as YMCKO which also includes a thermal

transfer black designed for printing barcodes

and a UV overlay to prevent the dye sublimation print from fading. The dye from the ribbon is applied to the plastic card as a

yellow ![]()

![]() magenta

magenta ![]() cyan

cyan ![]() black

black ![]() overlay

overlay ![]() yellow

yellow ![]() magenta

magenta ![]() cyan

cyan ![]() black

black ![]()

![]() overlay

overlay

All printers are also capable of printing in mono- chrome using a single colour ribbon. These ribbons are less expensive than full colour

black

Card Durability and Security

Encoding Data Onto The Card

Information can also be stored on the card in a number of different formats:

Barcode - These are available in a wide variety of types (known as symbologies) and are ideal for storing a card or

other number for time & attendance, asset tagging and data capture applications.

Magnetic Stripe - This is the most commonly used data storage format on a plastic card and can be encoded in both Hi-

Co (more durable) and

Applications |

|

| Usage |

Access Control |

|

| Daily |

|

|

|

|

Membership Cards |

|

| Weekly/Monthly |

|

|

|

|

Time and Attendance |

|

| Daily |

|

|

|

|

Debit/Credit/Loyalty Cards |

|

| Weekly/Monthly |

|

|

|

|

Smart Card - These can be used to store a much greater amount of information than a magnetic stripe. Most versions

can be encoded using a Zebra printer and one of the specialist encoder modules from DED. Smart Cards are commonly used for cashless payment, loyalty and bank/medical record storage.

Proximity Cards – These can store a similar amount of information to a smart card but the card does not need to come into physical contact with the reader. A small loop aerial located in the card surface allows information to be transmitted

between the card and reader from a small distance. Proximity cards are ideal for applications where a higher speed of transaction is required such as public transport passes.

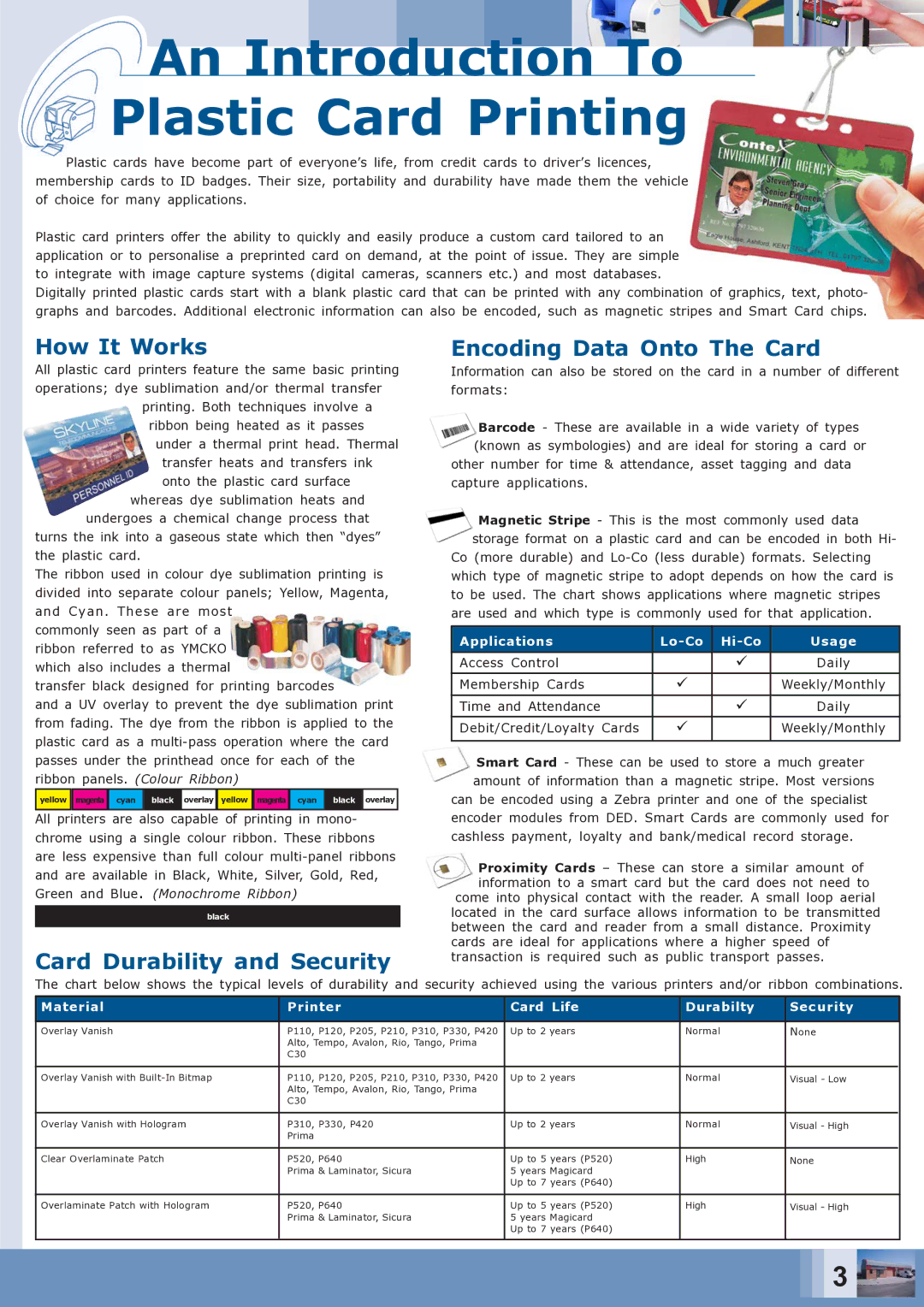

The chart below shows the typical levels of durability and security achieved using the various printers and/or ribbon combinations.

Material | Printer | Card Life | Durabilty | Security |

|

|

|

|

|

Overlay Vanish | P110, P120, P205, P210, P310, P330, P420 | Up to 2 years | Normal | None |

| Alto, Tempo, Avalon, Rio, Tango, Prima |

|

|

|

| C30 |

|

|

|

|

|

|

|

|

Overlay Vanish with | P110, P120, P205, P210, P310, P330, P420 | Up to 2 years | Normal | Visual - Low |

| Alto, Tempo, Avalon, Rio, Tango, Prima |

|

|

|

| C30 |

|

|

|

|

|

|

|

|

Overlay Vanish with Hologram | P310, P330, P420 | Up to 2 years | Normal | Visual - High |

| Prima |

|

|

|

|

|

|

|

|

Clear Overlaminate Patch | P520, P640 | Up to 5 years (P520) | High | None |

| Prima & Laminator, Sicura | 5 years Magicard |

|

|

|

| Up to 7 years (P640) |

|

|

|

|

|

|

|

Overlaminate Patch with Hologram | P520, P640 | Up to 5 years (P520) | High | Visual - High |

| Prima & Laminator, Sicura | 5 years Magicard |

|

|

|

| Up to 7 years (P640) |

|

|

|

|

|

|

|

3 ![]()