G2500 / G2500 OPS

7. Muffler

![]()

![]() WARNING

WARNING

If you do not attach the muffler correctly, after engine starts, the muffler will be loosen and the hightemperature exhaust gas spout. After cleaning the muffler, pay attention to fit up the muffler according to the explanation as follows.

1.Muffler body, muffler cover and baffle will be combined correctly.

2.Be sure the gasket is not broken. If it is broken, change to the new one.

3.Before tightening the screw, rub the gross on it.

4.After making a test run,

![]()

![]() WARNING

WARNING

Right after stopping the engine, do not touch the muffler with one's bare hands. It will cause to burn your hands.

If carbon clogs between the muffler, it will cause the

8. Recoil Starter

•For recoil maintenance, when attaching or detaching the starter of

•Don't pull the starter when detaching it from the unit. It will cause machine defect or serious injury by touching rotat- ing parts on your body part carelessly.

Select lever

Set direction

![]()

![]() WARNING

WARNING

Don't pull the starter when detaching it from the unit.

8. Maintenance of Saw Chain and Guide Bar

■Saw Chain

![]()

![]() WARNING

WARNING

It is very important for smooth and safe operation to always keep the cutters sharp.

The cutters need to be sharpened when:

•Sawdust becomes

•You need extra force to saw in.

•The cut path does not go straight.

•Vibration increases.

•Fuel consumption increases.

Cutter setting standards:

![]()

![]() WARNING

WARNING

Be sure to wear safety gloves.

Before filing:

•Make sure the saw chain is held securely.

•Make sure the engine is stopped.

•Use a round file of proper size for the chain.

Chain type: | 91VG / 25AP |

File size: | 5/32 in (4.0 mm) |

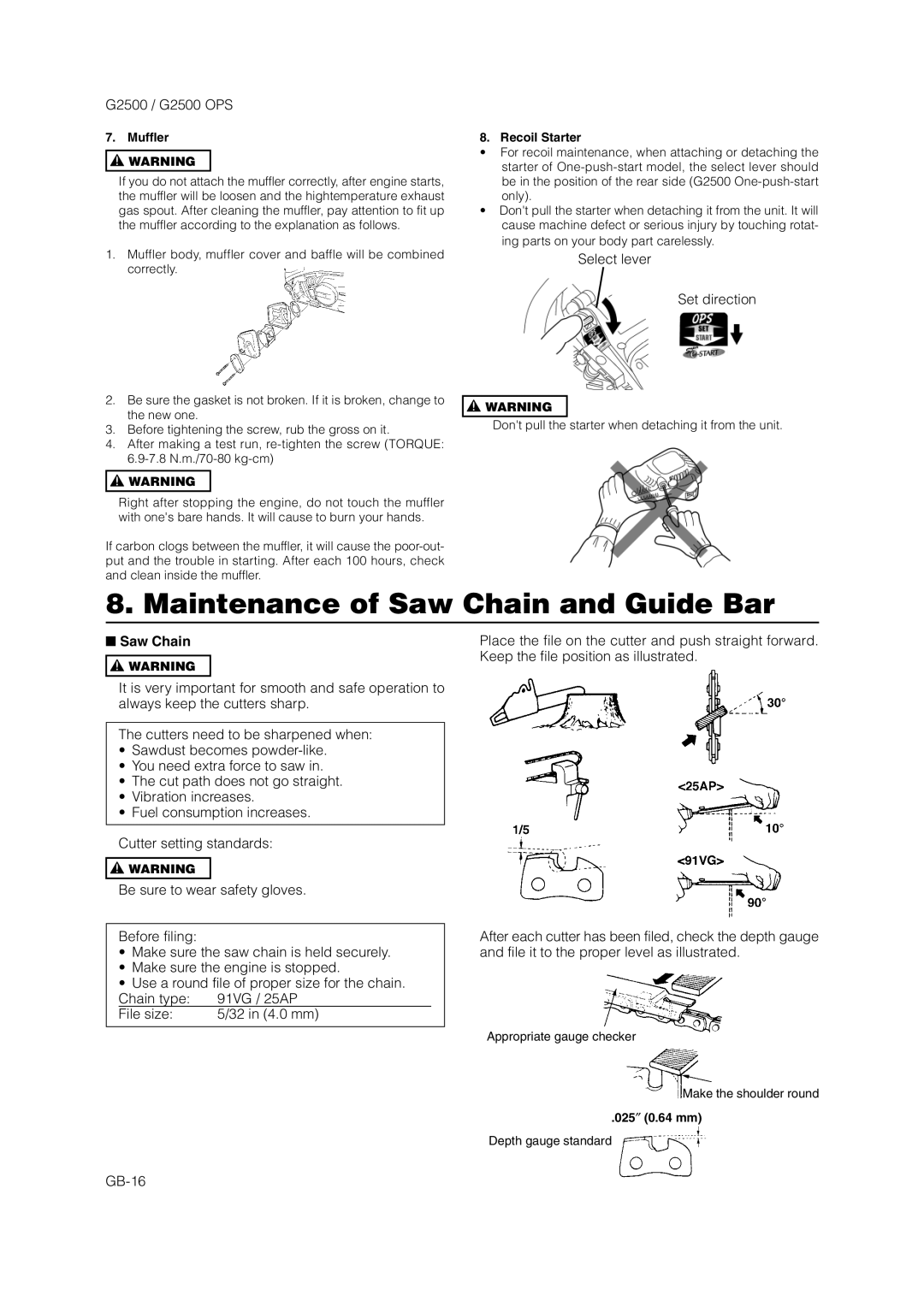

Place the file on the cutter and push straight forward. Keep the file position as illustrated.

After each cutter has been filed, check the depth gauge and file it to the proper level as illustrated.

Appropriate gauge checker

Make the shoulder round

.025″ (0.64 mm)

Depth gauge standard