PSZ2600 specifications

The Zenoah PSZ2600 is a versatile and robust handheld power tool designed for a variety of outdoor tasks, particularly in landscaping and gardening. This model stands out in the market due to its blend of advanced technology, user-friendly features, and outstanding performance.One of the main features of the Zenoah PSZ2600 is its powerful engine. The unit is equipped with a highly efficient 25.4cc two-stroke engine that delivers impressive power while maintaining low fuel consumption. This engine is not only designed for high performance but also for environmental responsibility, meeting stringent emissions regulations without sacrificing power output.

The PSZ2600 boasts a lightweight design, making it easy to handle during prolonged use. Weighing in at just over 5 kg, it reduces the strain on the user, allowing for extended periods of work without excessive fatigue. Its ergonomic design includes a comfortable handle and a well-balanced body, enhancing maneuverability and ease of operation.

Another notable characteristic of the PSP2600 is its advanced vibration-damping technology. This feature minimizes vibrations during operation, which not only improves user comfort but also increases control over the tool. This technology is particularly beneficial during extended use, reducing the risk of fatigue-related injuries.

The Zenoah PSZ2600 also offers a variety of attachments, making it a multifunctional tool. Its compatibility with several accessories enables users to transform it into a hedge trimmer, brush cutter, or pole saw, catering to diverse gardening and landscaping needs. This versatility makes it an excellent investment for both professionals and homeowners alike.

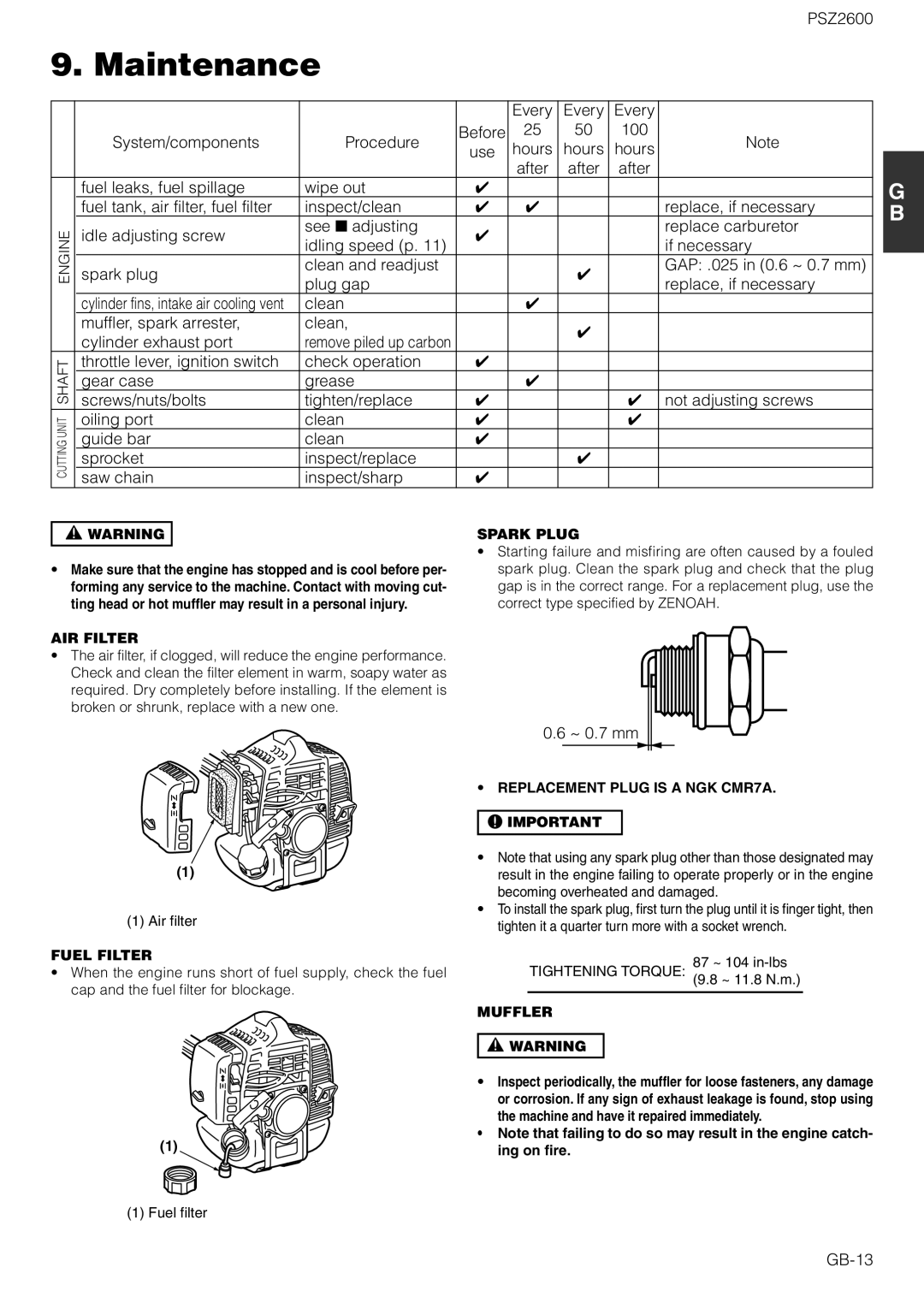

Ease of maintenance is another key aspect of the Zenoah PSZ2600. The tool includes a tool-less air filter cover, allowing for quick and easy access for cleaning or replacement. The fuel system is designed for easy refueling, further enhancing the user experience.

Overall, the Zenoah PSZ2600 stands as a testament to innovative engineering in handheld power tools. Its powerful engine, lightweight design, user-oriented features, and versatility make it an exceptional choice for anyone looking to tackle outdoor projects with efficiency and ease. Whether you're a professional landscaper or a gardening enthusiast, the PSZ2600 is designed to meet your needs effectively.