SECTION 6: MAKING ADJUSTMENTS

WARNING: Never attempt to make any adjustments while the engine is running, except where specified in operator’s manual.

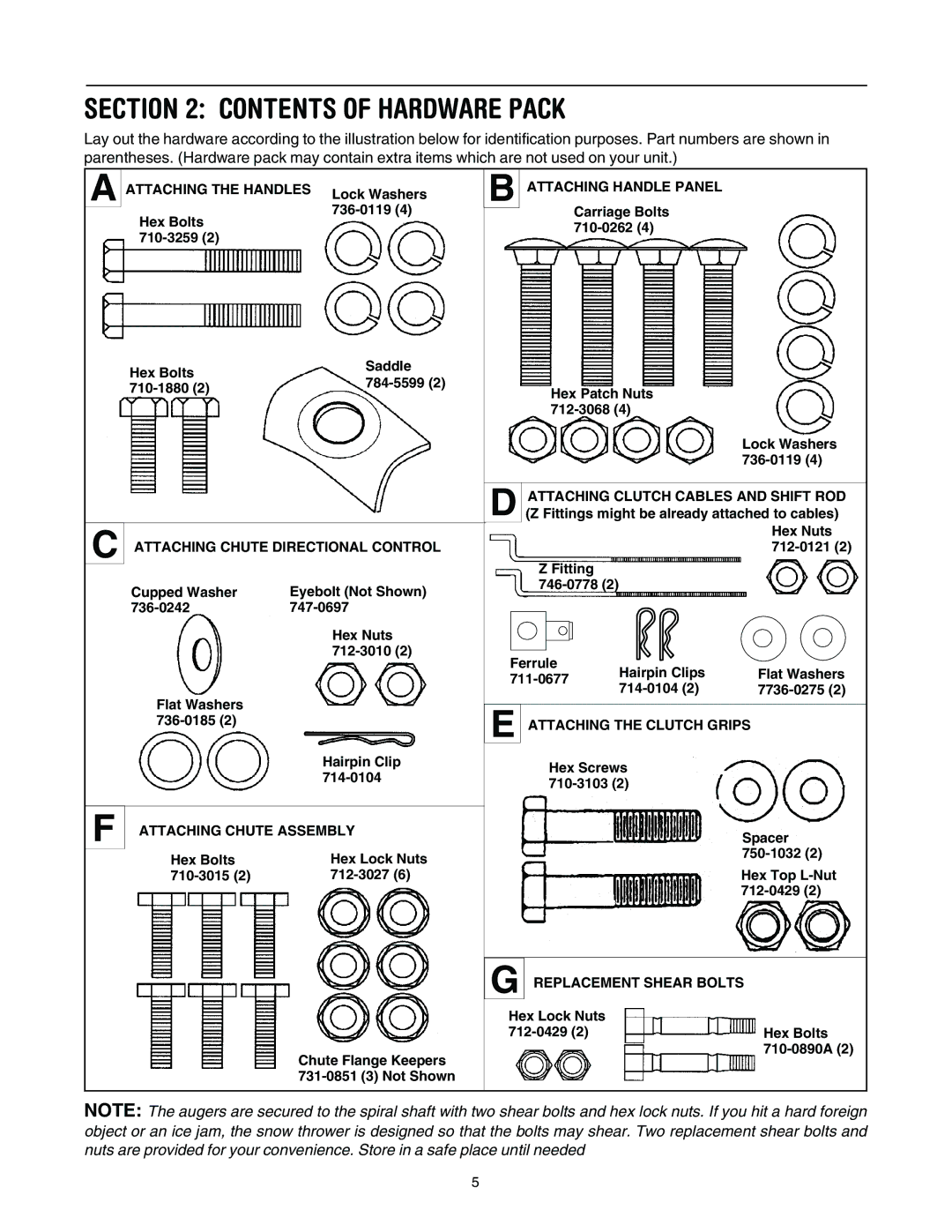

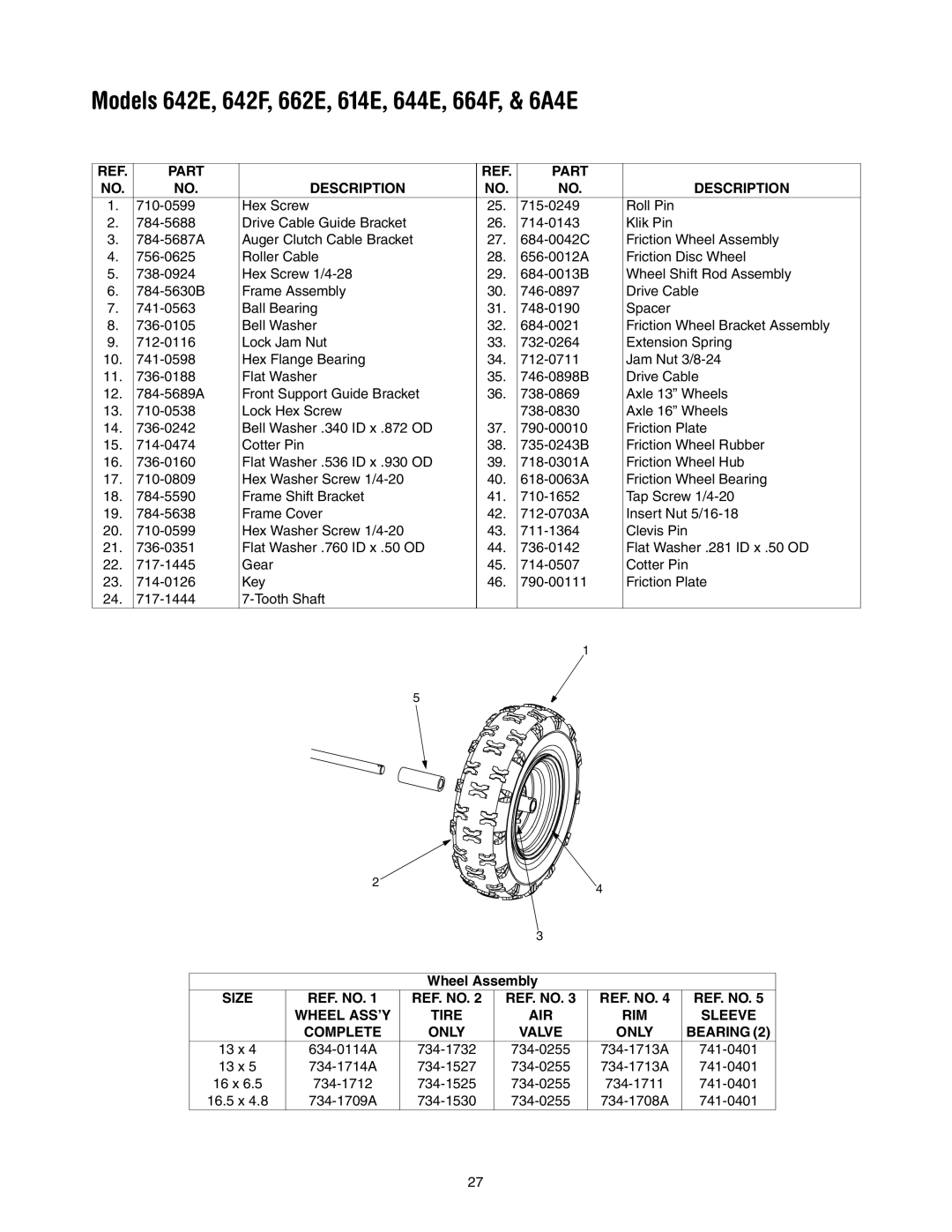

Tire Pressure (Pneumatic Tires)

•The tires are overinflated for shipping purposes. Before operating check tire pressure and reduce pressure to between 15psi and 20 psi.

NOTE: If the tire pressure is not equal in both tires, the unit may pull to one side or the other.

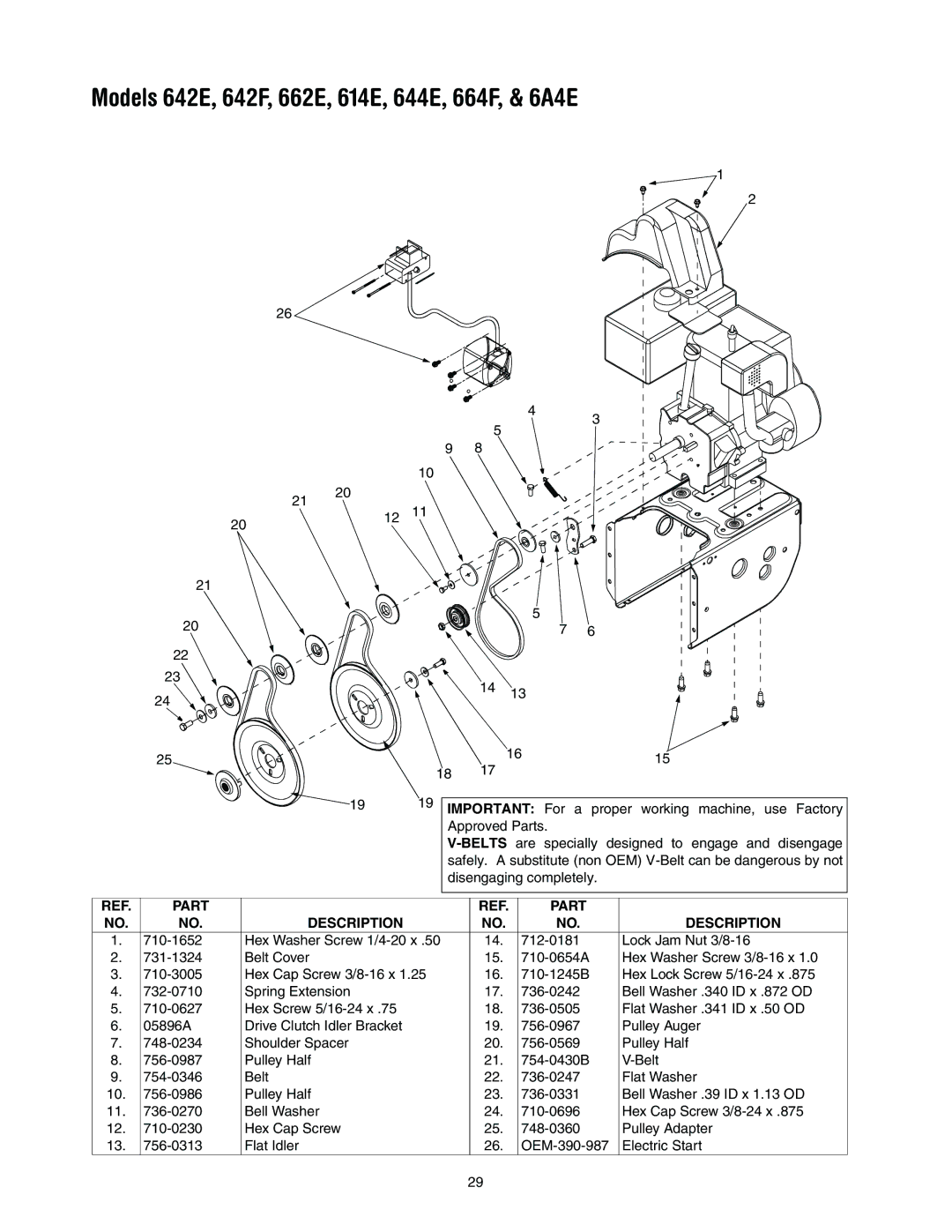

Traction Control and Shift Lever

•To check the adjustment of the traction control clutch and shift lever, proceed as follows:

•With the engine off, move the shift lever all the way forward to the highest speed. With the traction control lever released, push the snow thrower forward. The unit should roll forward. Then engage the traction control grip. The wheels should stop turning.

•Now release the traction control grip and push the unit again.

•Move the shift lever back to the fast reverse position then all the way forward again. There should be no resistance in the shift lever, and the wheels should keep turning.

•If you have resistance when moving the shift lever or the wheels stop when they should not, loosen the jam nut on the traction control cable and unthread the cable one turn.

•If the wheels do not stop when you engage the traction control clutch grip, loosen the jam nut on the traction control cable and thread the cable in one turn.

•Recheck the adjustment and repeat as necessary. Tighten the jam nut to secure the cable when correct adjustment is reached.

WARNING: Drain the gasoline out of snow thrower engine, place a piece of plastic film under the gas cap to avoid spillage before beginning the job.

To test further for correct adjustment, if necessary, proceed as follows:

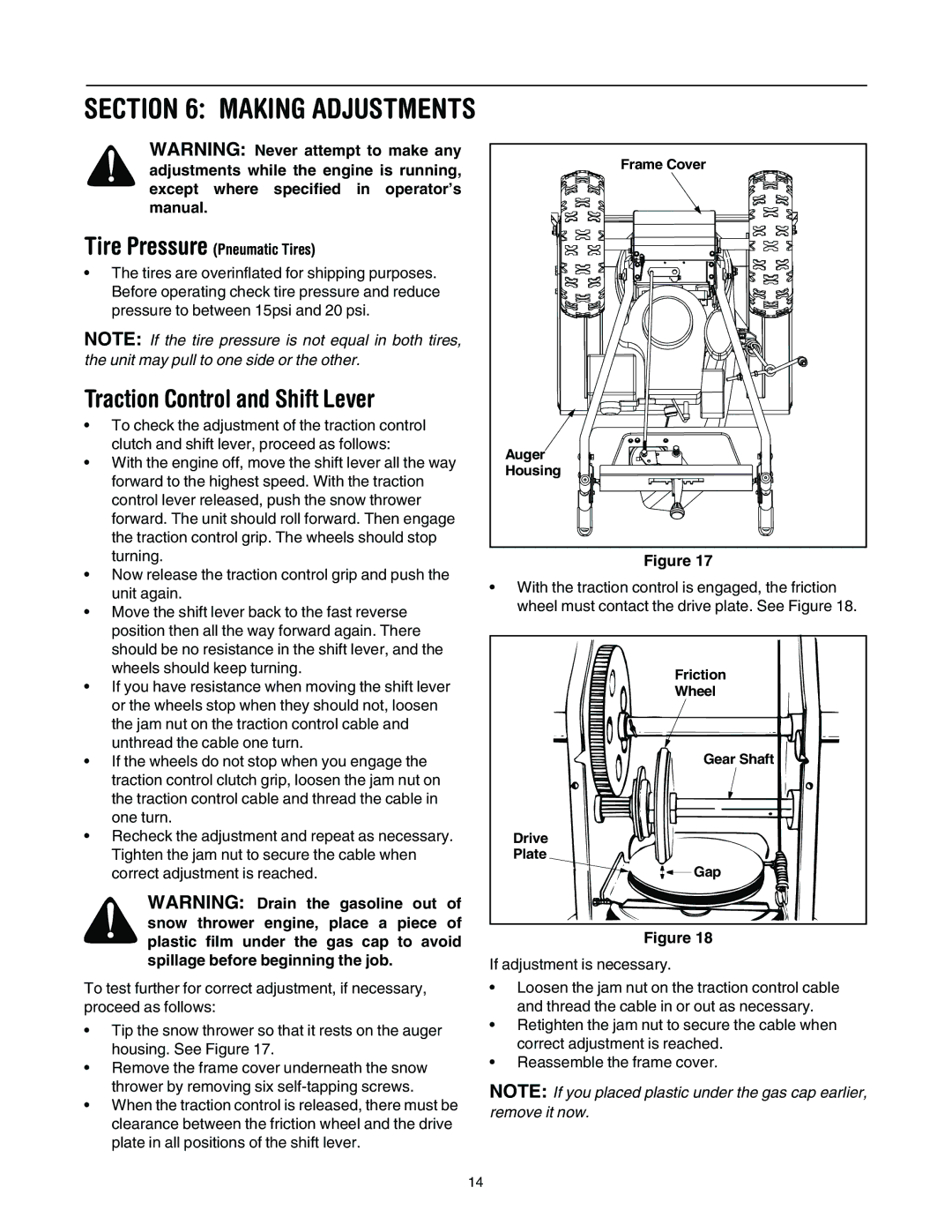

•Tip the snow thrower so that it rests on the auger housing. See Figure 17.

•Remove the frame cover underneath the snow thrower by removing six

•When the traction control is released, there must be clearance between the friction wheel and the drive plate in all positions of the shift lever.

Frame Cover |

Auger |

Housing |

Figure 17

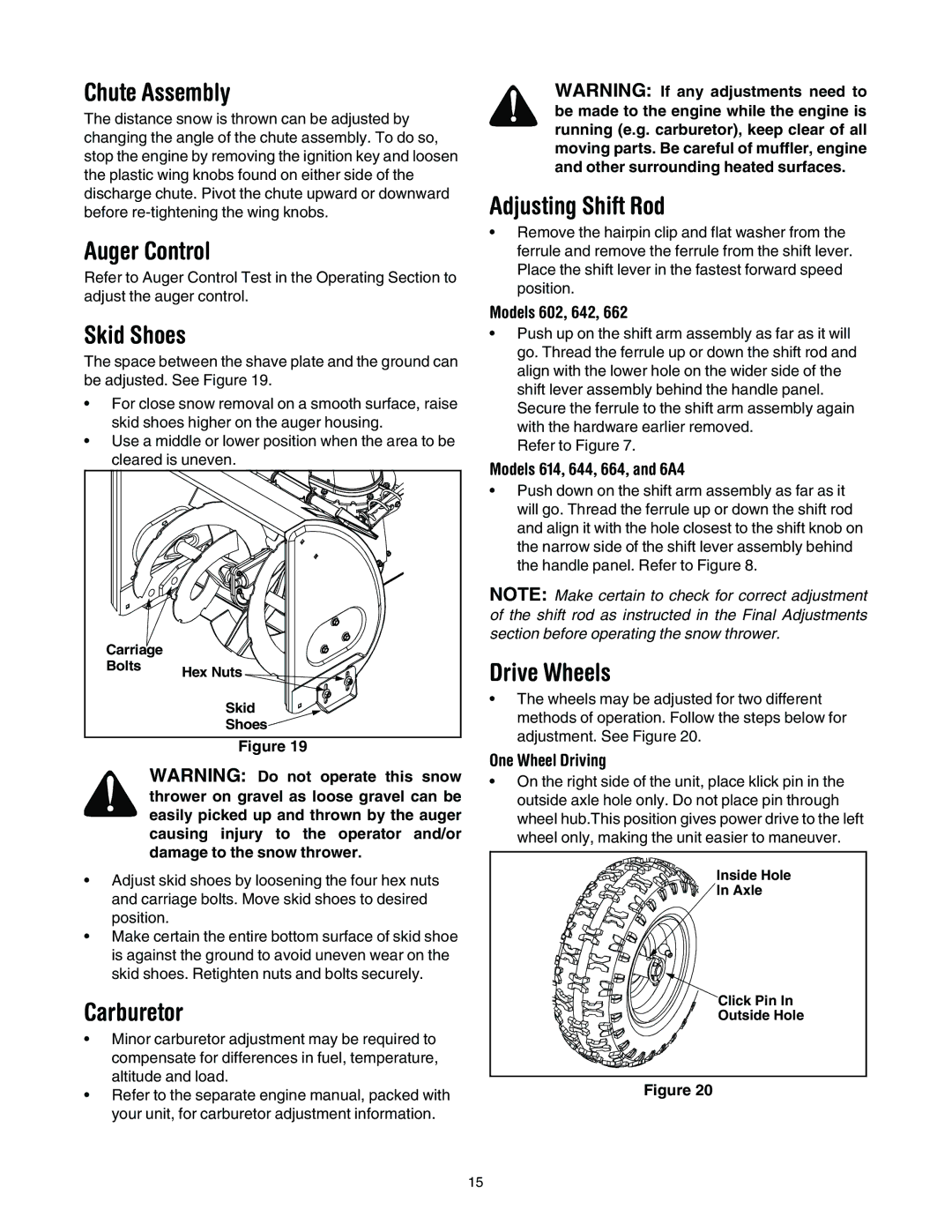

•With the traction control is engaged, the friction wheel must contact the drive plate. See Figure 18.

Friction |

Wheel |

Gear Shaft |

Drive |

Plate |

Gap |

Figure 18

If adjustment is necessary.

•Loosen the jam nut on the traction control cable and thread the cable in or out as necessary.

•Retighten the jam nut to secure the cable when correct adjustment is reached.

•Reassemble the frame cover.

NOTE: If you placed plastic under the gas cap earlier, remove it now.

14