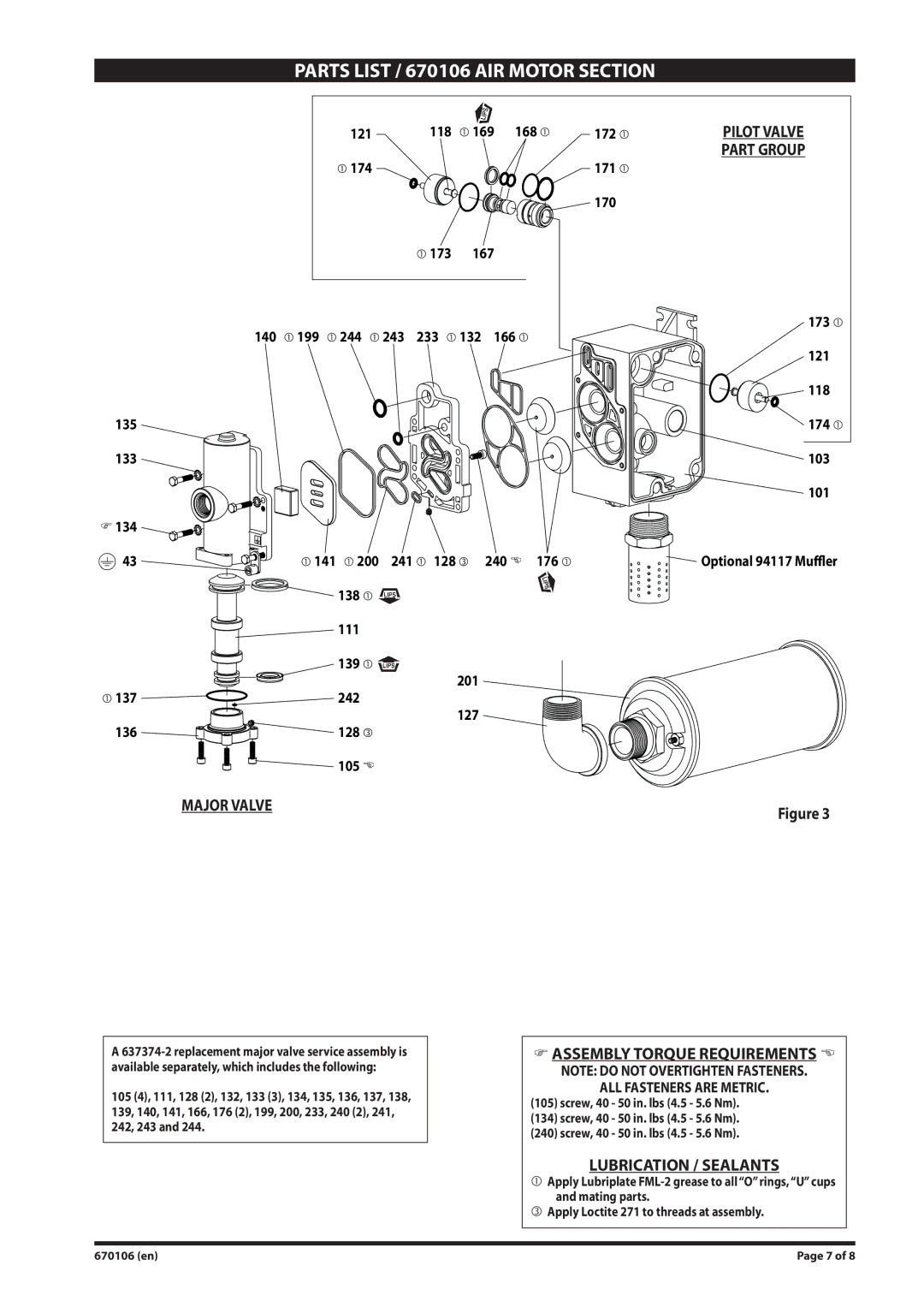

PARTS LIST / 670106 AIR MOTOR SECTION

9Indicates parts included in 637421 air section repair kit.

AIR MOTOR PARTS LIST

Item | Description (size) | Qty | Part No. | [Mtl] |

101 | Center Body | (1) | 94028 | [A] |

|

|

|

|

|

103 | Bushing | (1) | 94092 | [D] |

|

|

|

|

|

105 | Screw (M6 x 1 - 6g x 20 mm) | (4) | 95887 | [SS] |

|

|

|

|

|

111 | Spool | (1) | 95651 | [D] |

|

|

|

|

|

118 | Actuator Pin (0.250” x 2.276” long) | (2) | 94083 | [SS] |

|

|

|

|

|

121 | Sleeve | (2) | 94084 | [D] |

|

|

|

|

|

127 | 90˚ St. Elbow | (1) | 94860 | [C / I] |

|

|

|

|

|

128 | Set Screw (1/4” - 20 x 1/4”) | (2) | [SS] | |

|

|

|

|

|

9 132 | Gasket | (1) | 94099 | [B] |

133 | Lockwasher (1/4”) | (3) | [C] | |

|

|

|

|

|

134 | Screw (M6 x 1 - 6g x 30 mm) | (4) | 96358 | [SS] |

|

|

|

|

|

135 | Valve Housing | (1) | [A] | |

|

|

|

|

|

136 | Plug | (1) | 96335 | [A] |

|

|

|

|

|

9 137 | “O” Ring (1/16” x 2” o.d.) | (1) | [B] | |

9 138 | “U” Cup (3/16” x 1.792” o.d.) | (1) | 95966 | [B] |

9 139 | “U” Cup (3/16” x | (1) | [B] | |

140 | Valve Insert | (1) | 95650 | [Ck] |

|

|

|

|

|

141 | Valve Plate | (1) | 95659 | [Ck] |

|

|

|

|

|

9 166 | Track Gasket | (1) | 94026 | [B] |

9 167 | Pilot Assembly (includes 168 and 169) | (1) | 67164 | [D] |

|

|

|

|

|

MATERIAL CODE

[A] = | Aluminum | [Ck] = Ceramic | [Sp] = Santoprene | ||

[B] = | Nitrile | [D] = | Acetal | [SS] = | Stainless Steel |

[Br] = | Brass | [I] = | Cast Iron | [U] = | Polyurethane |

[C] = | Carbon Steel |

|

|

|

|

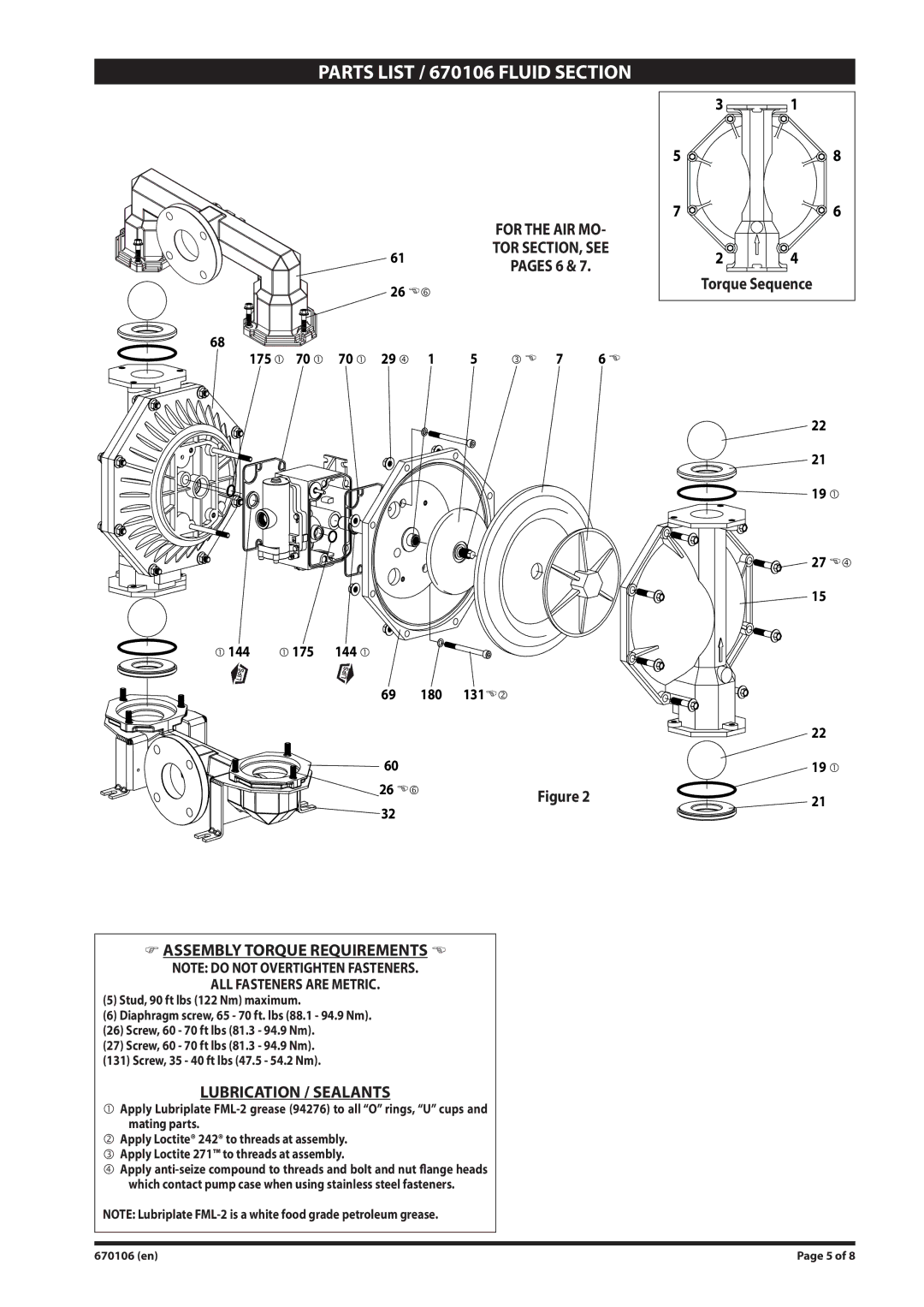

AIR MOTOR SECTION SERVICE

Service is divided into two parts - 1. Pilot Valve, 2. Major Valve.

GENERAL REASSEMBLY NOTES:

yAir Motor Section service is continued from Fluid Section repair.

yInspect and replace old parts with new parts as neces- sary. Look for deep scratches on metallic surfaces, and nicks or cuts in “O” rings.

yTake precautions to prevent cutting “O” rings upon instal- lation.

yLubricate “O” rings with Lubriplate

yDo not

y

ySERVICE TOOLS - To aid in the installation of (168) “O” rings onto the (167) pilot piston, use tool #

PILOT VALVE DISASSEMBLY

1.A light tap on (118) should expose the opposite (121) sleeve, (167) pilot piston and other parts.

2.Remove (170) sleeve. Inspect inner bore of sleeve for damage.

PILOT VALVE REASSEMBLY

1.Clean and lubricate parts not being replaced from service kit.

Item | Description (size) | Qty | Part No. | [Mtl] |

168 | “O” Ring (3/32” x 5/8” o.d.) | (2) | 94433 | [U] |

169 | “U” Cup (1/8” x 7/8” o.d.) | (1) | [B] | |

170 | Piston Sleeve | (1) | 94081 | [Br] |

9 171 | “O” Ring (3/32” x | (1) | [B] | |

9 172 | “O” Ring (1/16” x | (1) | [B] | |

9 173 | “O” Ring (1/16” x | (2) | [B] | |

9174 | “O” Ring (1/8” x 1/2” o.d.) | (2) | [B] | |

9 176 | Diaphragm (check valve) | (2) | 94102 | [Sp] |

9 199 | Track Gasket | (1) | 95666 | [B] |

9 200 | Gasket | (1) | 95665 | [B] |

201 | Muffler (includes item 127) | (1) | 94810 |

|

233 | Adapter Plate | (1) | 96336 | [A] |

240 | Screw (M6 x 1 - 6g x 16 mm) | (2) | 95991 | [SS] |

9 241 | Track Gasket | (1) | 96344 | [B] |

9 242 | “O” Ring (1/16” x 7/32” o.d.) | (1) | [B] | |

9 243 | “O” Ring (1/8” x 5/8” o.d.) | (1) | [B] | |

9 244 | “O” Ring (1/8” x 7/8” o.d.) | (1) | [B] | |

9 | Lubriplate | (1) | 94276 |

|

| Lubriplate grease packets | (10) | 637308 |

|

Indicates items included in

2.Install new (171 and 172) “O” rings. Replace (170) sleeve.

3.Install new (168) “O” rings and (169) seal - Note lip direc- tion. Lubricate and replace.

4.Reassemble remaining parts. Replace (173 and 174) “O” rings.

MAJOR VALVE DISASSEMBLY

1.Remove (135) valve block and (233) adapter plate, expos- ing (166 and 132) gaskets and (176) checks.

2.Remove (233) adapter plate, releasing (140) valve insert, (141) valve plate, (199, 200 and 241) gaskets and (243 and 244) “O” rings.

3.Remove (136) plug and (137) “O” ring, releasing (111) spool.

MAJOR VALVE REASSEMBLY

1.Install new (138 and 139) “U” cups on (111) spool - LIPS MUST FACE EACH OTHER.

2.Insert (111) spool into (135) valve housing.

3.Install (137 and 242) “O” rings on (136) plug and assemble plug to (135) valve housing, securing with (105) screws.

4.Install (140) valve insert, (141) valve plate, (199) gasket and (243 and 244) “O” rings into (135) valve housing. NOTE: Assemble (140) valve insert with “dished” side to- ward (141) valve plate. Assemble (141) valve plate with part number identification toward (140) valve insert.

5.Assemble (200 and 241) gaskets and (233) adapter plate to (135) valve housing, securing with (240) screws.

6.Assemble (132 and 166) gaskets and (176) checks to (101) center body.

7.Assemble (135) valve housing and components to (101) center body, securing with (134) screws.

Page 6 of 8 | 670106 (en) |