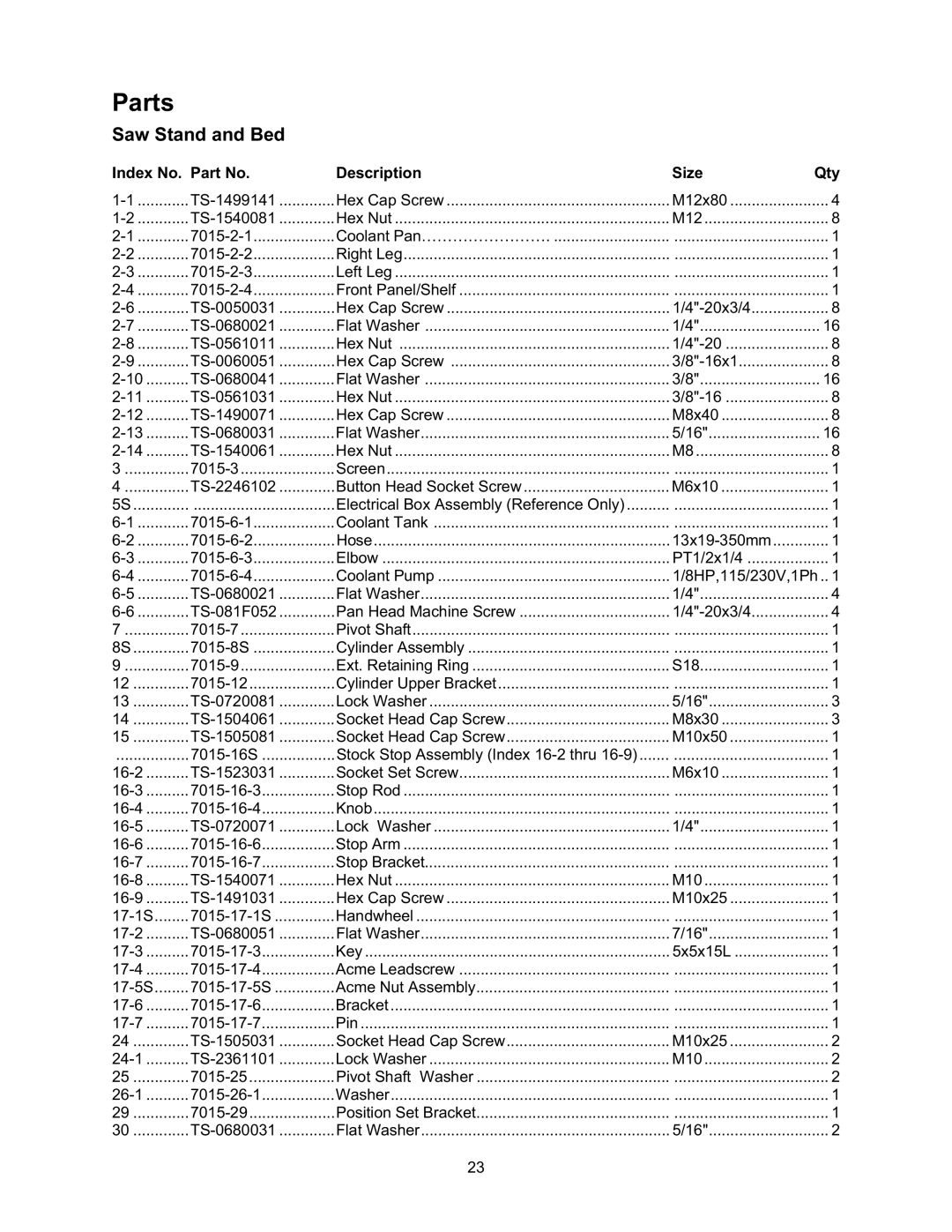

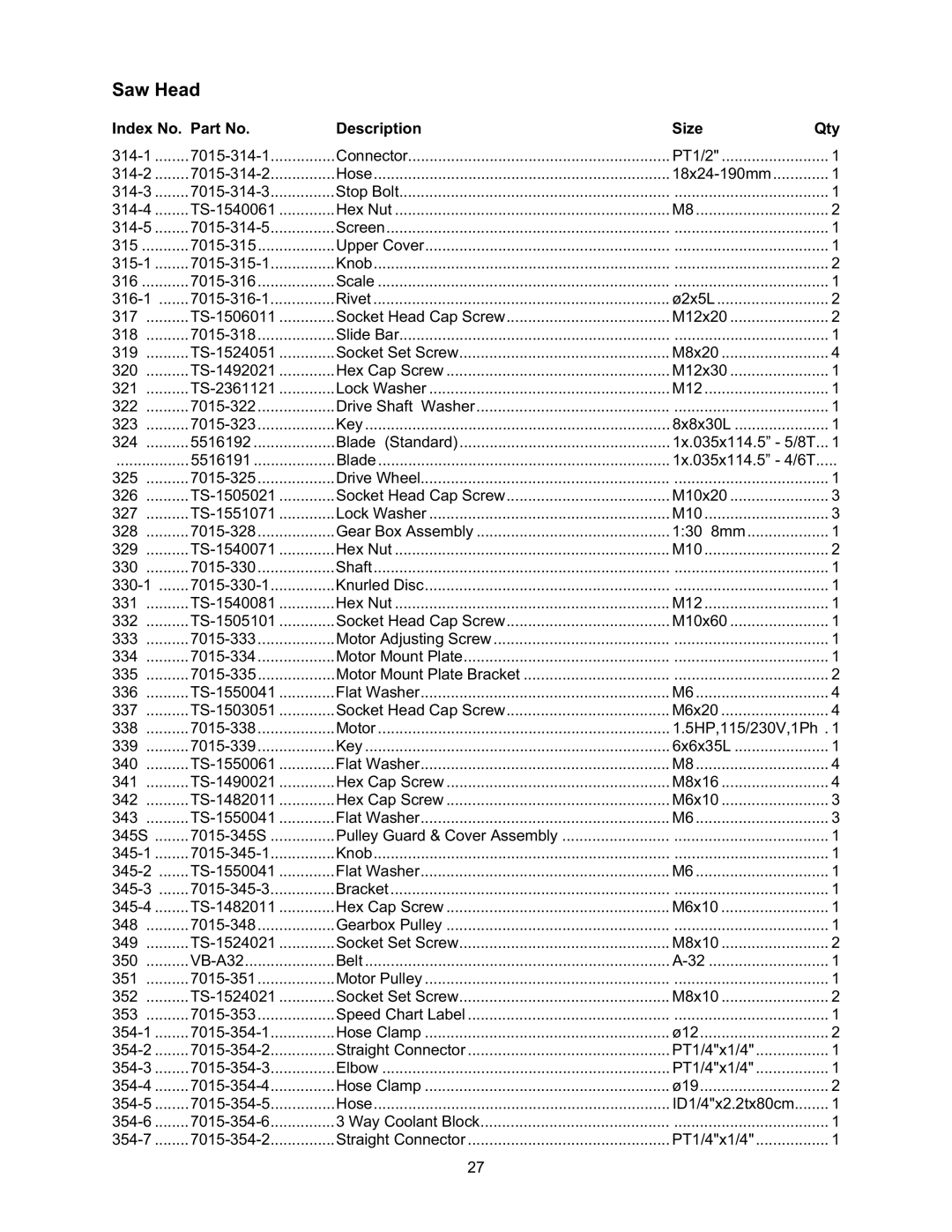

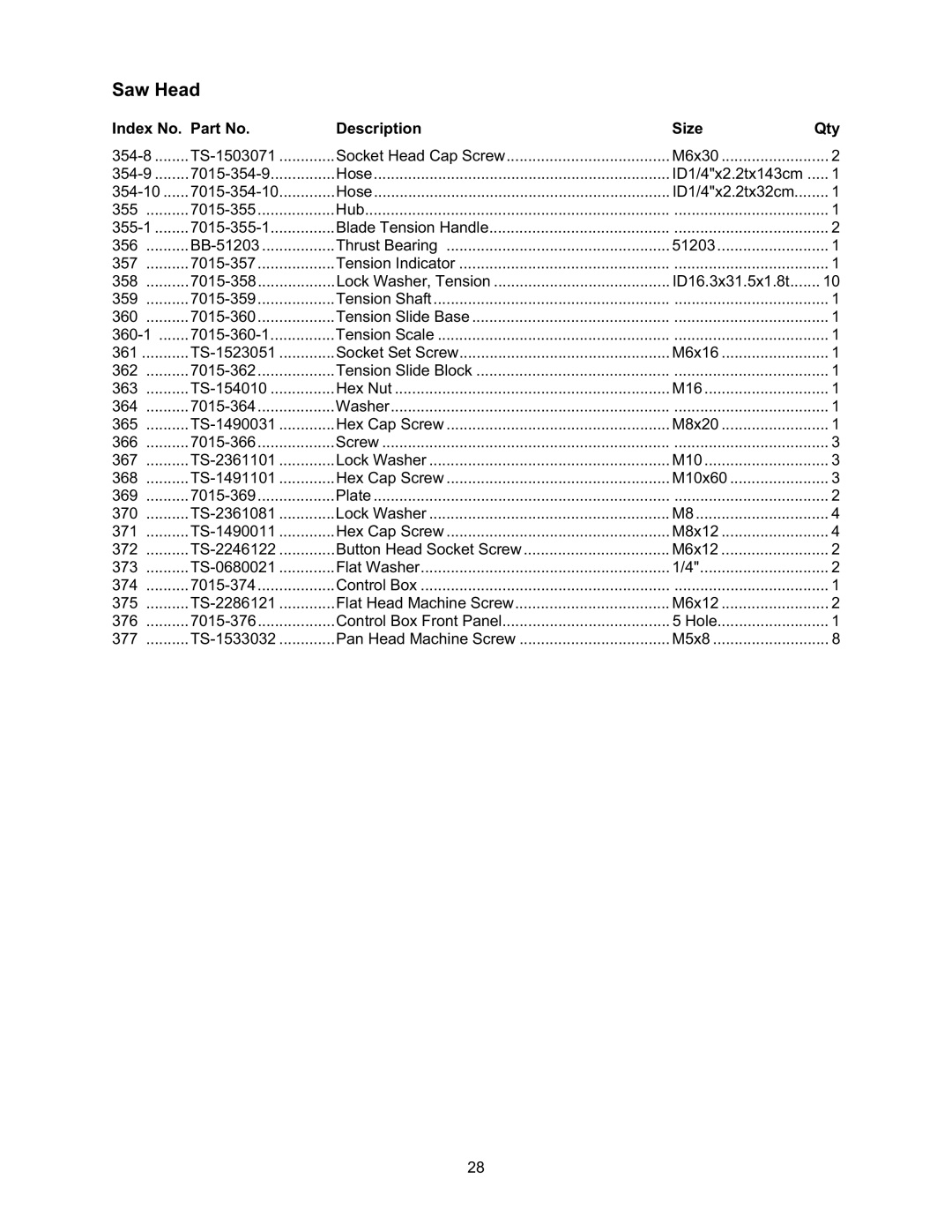

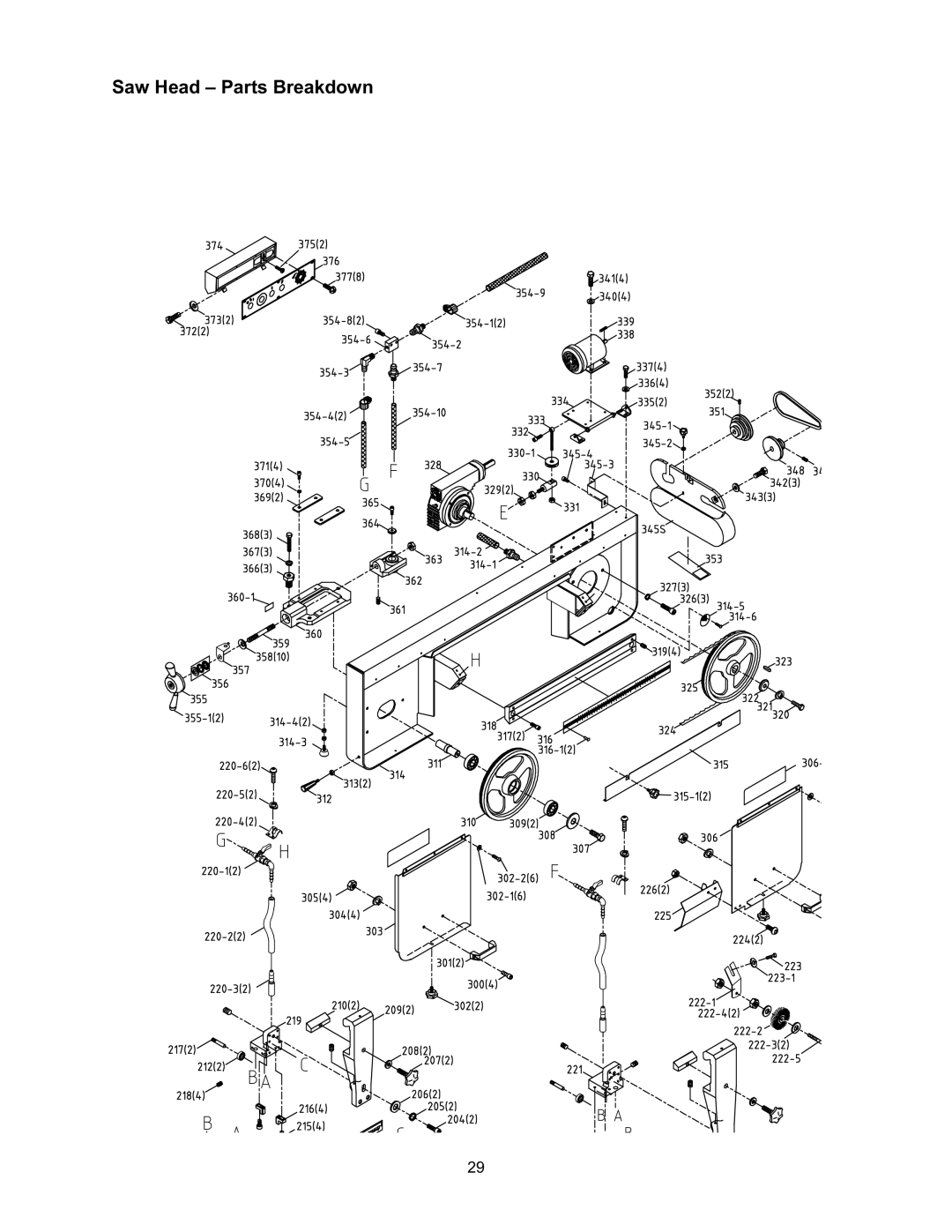

Saw Head

Index No. | Part No. | Description | Size | Qty |

Socket Head Cap Screw | M6x30 | 2 | ||

Hose | ID1/4"x2.2tx143cm | 1 | ||

Hose | ID1/4"x2.2tx32cm | 1 | ||

355 | Hub | .................................... | 1 | |

Blade Tension Handle | .................................... | 2 | ||

356 | Thrust Bearing | 51203 | 1 | |

357 | Tension Indicator | .................................... | 1 | |

358 | Lock Washer, Tension | ID16.3x31.5x1.8t | 10 | |

359 | Tension Shaft | .................................... | 1 | |

360 | Tension Slide Base | .................................... | 1 | |

Tension Scale | .................................... | 1 | ||

361 | Socket Set Screw | M6x16 | 1 | |

362 | Tension Slide Block | .................................... | 1 | |

363 | Hex Nut | M16 | 1 | |

364 | Washer | .................................... | 1 | |

365 |

| Hex Cap Screw | M8x20 | 1 |

366 | Screw | .................................... | 3 | |

367 | Lock Washer | M10 | 3 | |

368 | Hex Cap Screw | M10x60 | 3 | |

369 | Plate | .................................... | 2 | |

370 | Lock Washer | M8 | 4 | |

371 | Hex Cap Screw | M8x12 | 4 | |

372 | Button Head Socket Screw | M6x12 | 2 | |

373 | Flat Washer | 1/4" | 2 | |

374 | Control Box | .................................... | 1 | |

375 | Flat Head Machine Screw | M6x12 | 2 | |

376 | Control Box Front Panel | 5 Hole | 1 | |

377 | Pan Head Machine Screw | M5x8 | 8 |

28