electric current to reduce the risk of electric shock to the operator.

Improper connection of the equipment- grounding conductor can result in risk of electric shock. The conductor, with insulation having an outer surface that is green with or without yellow stripes, is the

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

The sander should be connected to a dedicated circuit with a minimum 100 Amp service. The sander has been factory wired to run at 230 volt operation. It can be converted to 460 volt if desired. See the appropriate sections below.

8.2230 Volt Operation

The sander may be fitted with a 230 volt plug, or may be

Refer to the diagram inside the sander’s electrical box for clarification of electrical connections. These diagrams are also shown in sections 17.0 and 18.0 of this manual.

1.Make sure the machine’s plug is disconnected from the power source. If it will be

2.Make sure the power source corresponds to the specifications of the sander as recorded on the sander’s motor plate.

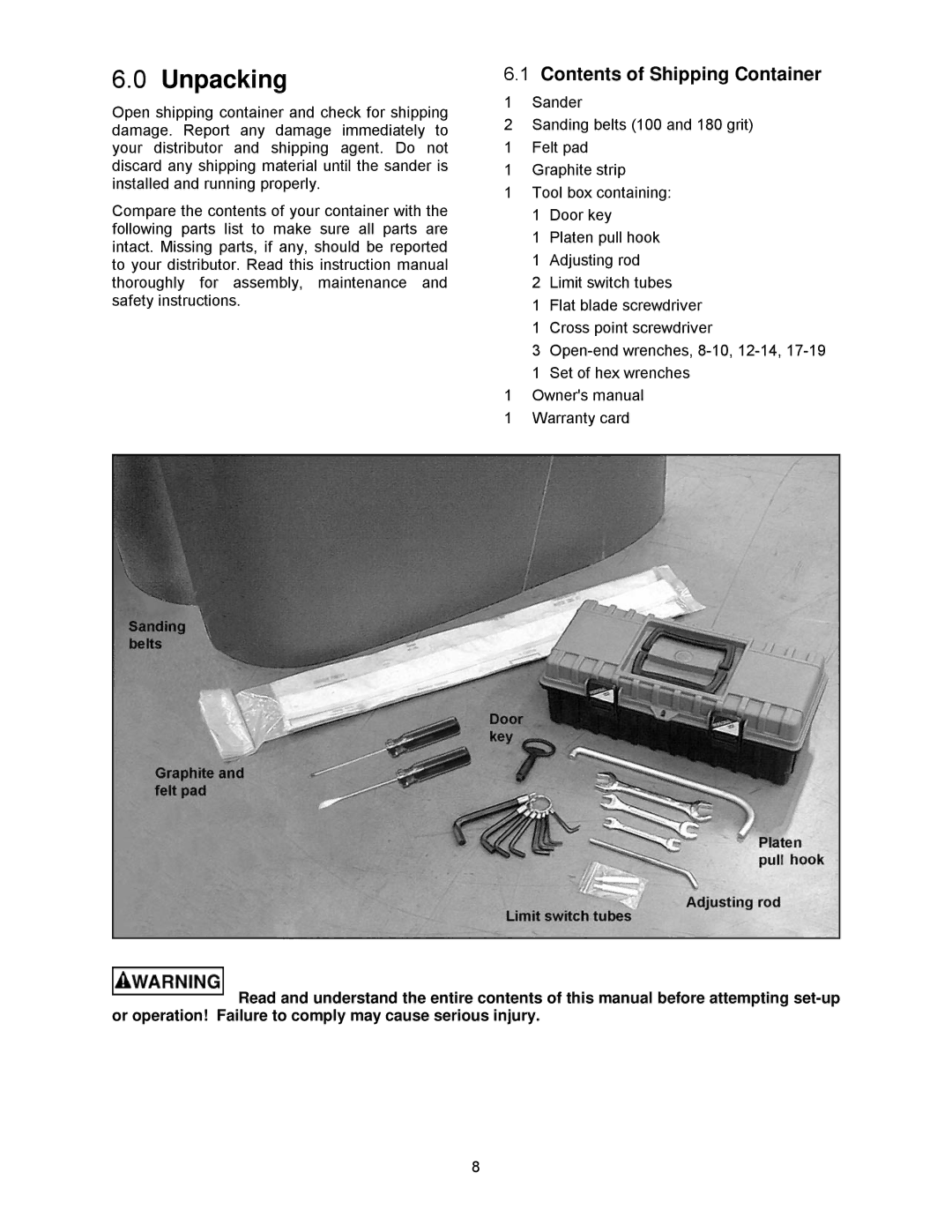

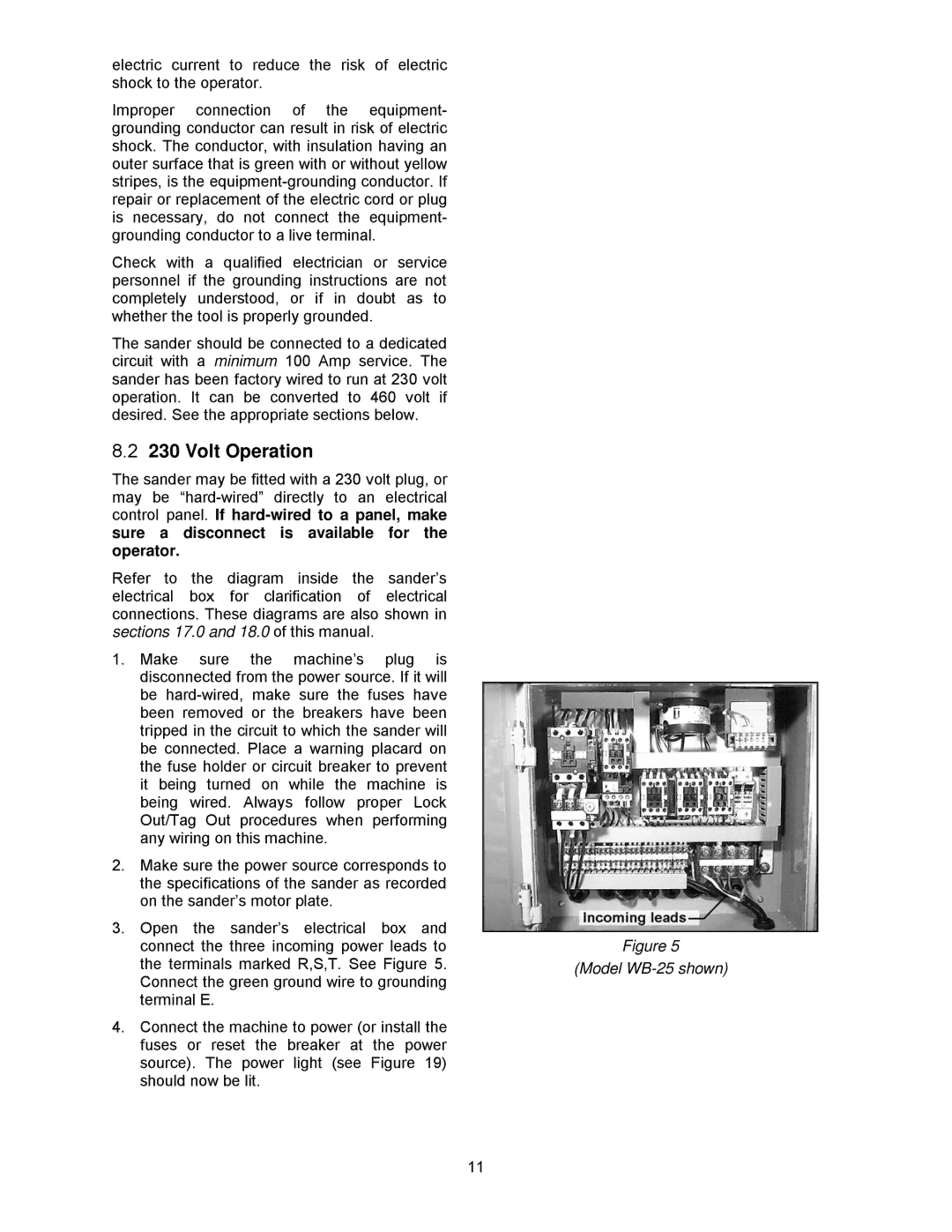

3.Open the sander’s electrical box and connect the three incoming power leads to the terminals marked R,S,T. See Figure 5. Connect the green ground wire to grounding terminal E.

4.Connect the machine to power (or install the fuses or reset the breaker at the power source). The power light (see Figure 19) should now be lit.

Figure 5

(Model WB-25 shown)

11