Repair |

|

|

| P 9/ 15 | |

|

|

|

| ||

[3] DISASSEMBLY/ASSEMBLY |

|

|

| ||

[3] |

|

| Fig. 32 |

| |

ASSEMBLING |

|

|

| Guide plate | |

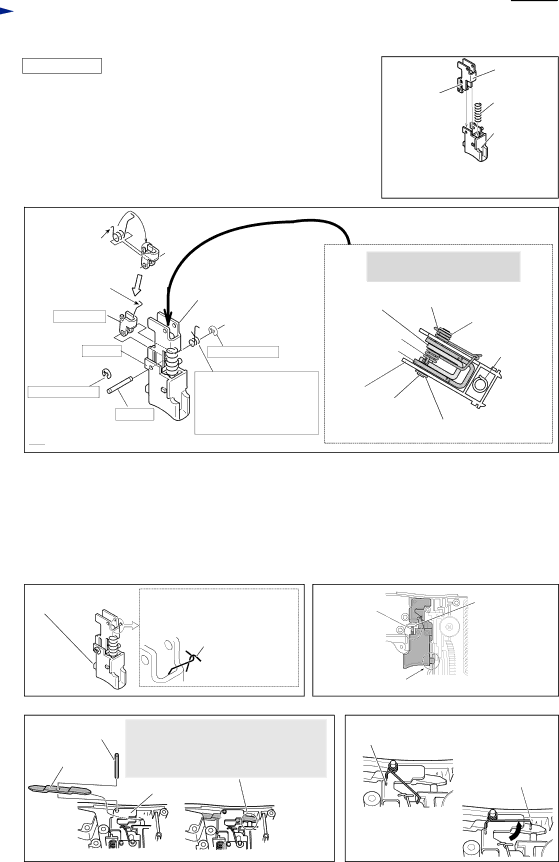

(1) Insert Guide plate and Compression spring 4 into Trigger. (Fig. 32) | The groove |

| |||

(2) Hook the short end of Torsion spring 3 with Swing arm, and then insert the | Compression | ||||

of Guide plate | |||||

Torsion spring 3 into Swing arm. (Fig. 33) |

| spring 4 | |||

| to pass Pin 2.5 | ||||

(3) Insert Swing arm into Guide plate so that Pin 2.5 can be passed through | Trigger | ||||

| |||||

the grooves of Guide plate in the next step. (Figs. 32 and 33) |

|

| |||

|

|

| |||

(4) Pass Pin 2.5 through the holes of Trigger and the grooves of Guide plate |

|

| |||

while setting two Torsion springs 3 as drawn in Figs. 14 and 33 and secure | Inserting position of Guide plate and | ||||

Pin 2.5 with two Stop rings |

| ||||

Fig. 33 |

|

| Compression spring 4 to Trigger | ||

|

|

|

| ||

short end of |

|

|

|

| |

Torsion spring 3 |

|

|

|

| |

for Swing arm |

| Viewed from the upper side of | |||

long end of Torsion |

| ||||

| the assembled Trigger Section | ||||

spring 3 for hooking |

| ||||

|

|

|

| ||

the other Torsion | Guide plate | Swing arm | Torsion spring 3 | Housing R side | |

spring 3 | Housing R side |

| |||

Swing arm |

|

| Stop ring | ||

|

| Torsion spring 3 | |||

|

| Compression | |||

Trigger | Stop ring | Guide plate | |||

spring 4 | |||||

Stop ring |

|

Housing L side | Pin 2.5 |

![]()

![]() : The components of Trigger set

: The components of Trigger set

Torsion spring 3 between | Trigger |

|

Trigger and Stop ring |

| |

(Hook the shot end to | Pin 2.5 |

|

the projection of Trigger. |

| Stop ring |

Refer to Fig. 14.) | Housing L side | |

|

|

(5) Hook one Torsion spring 3 with the other (Ref. Fig. 33) as drawn in Fig. 34.

Note: Torsion spring 3 for Swing arm is different from Torsion spring 3 for Guide plate and Switch arm.

(6)Hook the projection of Trigger with the notch of Lock arm. (Figs. 34 and 35)

(7)Install Trigger section in Housing L while compressing Compression spring 4 to put it on the rib of Housing L as drawn in Fig. 35.

(8)After putting Switch arm in Guide plate, insert Pin 2.5 through the holes of Guide plate and Switch arm. Pay attention to the direction of Switch arm. Refer to Fig. 36.

(9)Install Torsion spring 4 for Guide plate and Switch arm (Ref. Fig. 33) as drawn in Fig 37.

Fig. 34

Fig. 35

Projection of Trigger (for Lock arm)

Long end of Torsion spring 3 (come from inside of Swing arm)

![]() long end of Torsion spring 3

long end of Torsion spring 3

(located out of Trigger)

Compression | Rib of Housing L |

spring 4 | for compression |

| spring 4 |

Projection of Trigger hooked with notch of Lock arm

Fig. 36

Pin 2.5 | Note: Switch arm has to be assembled | |

so as to contact Push pin. | ||

| ||

Switch arm | Otherwise, the machine does not | |

run even if Switch trigger is pulled. | ||

| ||

| Guide plate |

Fig. 37

(1)Put short end of Torsion spring 4 on Guide plate.

(2) Put short end of Torsion spring 4 on Guide plate.