Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

Tool will not start. | 1. | Cord not connected. | 1. | Check that cord is plugged in. |

| 2. | No power at outlet. | 2. | Check power at outlet. If outlet is unpowered, |

|

|

|

| turn off tool and check circuit breaker. If breaker |

|

|

|

| is tripped, make sure circuit is right capacity |

|

|

|

| for tool and circuit has no other loads. |

| 3. | Tool’s thermal reset breaker | 3. | Turn off tool and allow to cool. |

|

| tripped (if equipped). |

| Press reset button on tool. |

| 4. | Internal damage or wear. | 4. | Have technician service tool. |

|

| (Carbon brushes or |

|

|

|

| switch, for example.) |

|

|

Tool operates slowly. | Extension cord too long or | Eliminate use of extension cord. If an extension cord | ||

| wire size too small. | is needed, use shorter/heavier gauge cord. See | ||

|

|

| Extension Cords in Grounding section on page 5. | |

Performance | 1. | Accessory dull or damaged. | 1. | Keep cutting accessories sharp. Replace as needed. |

decreases over time. | 2. | Carbon brushes worn | 2. | Have qualified technician replace brushes. |

|

| or damaged. |

|

|

Excessive noise | Internal damage or wear. (Carbon | Have technician service tool. | ||

or rattling. | brushes or bearings, for example.) |

|

| |

Overheating. | 1. | Forcing tool to work too fast. | 1. | Allow tool to work at its own rate. |

| 2. | Accessory misaligned. | 2. | Check and correct accessory to |

|

|

|

| fence and/or table alignment. |

| 3. | Accessory dull or damaged. | 3. | Keep cutting accessories sharp. Replace as needed. |

| 4. | Blocked motor housing vents. | 4. | Wear |

|

|

|

| NIOSH‑approved dust mask/respirator while |

|

|

|

| blowing dust out of motor using compressed air. |

| 5. | Motor being strained by long or | 5. | Eliminate use of extension cord. If an extension |

|

| small diameter extension cord. |

| cord is needed, use one with the proper |

|

|

|

| diameter for its length and load. See Extension |

|

|

|

| Cords in Grounding section on page 5. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service.

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

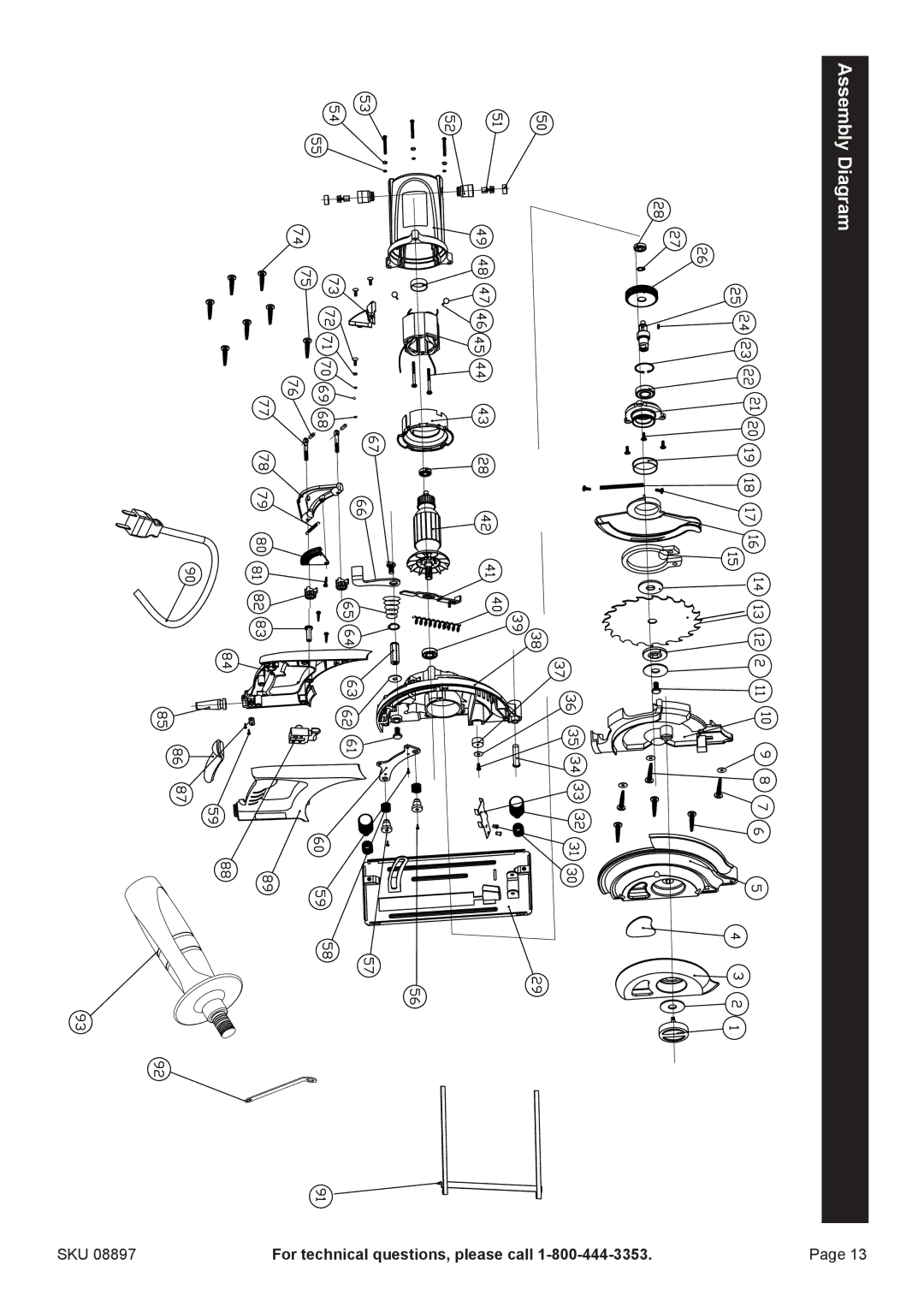

Note: Some parts are listed and shown for illustration purposes only, and are not available individually as replacement parts.

SKU 08897 | For technical questions, please call | Page 11 |