OWNER’S GUIDE & INSTALLATION INSTRUCTIONS

Ultrasonic Speed Sensor

with Valve and Temperature

Model

U.S. Patents 5,186,050; 6,426,918

IMPORTANT: Please read these instructions completely before proceeding with the installation. These instructions supersede any other instructions in your instrument manual if they differ.

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

How the Ultrasonic Speed Sensor Works

The speed sensor uses ultrasonic pulses to collect echoes from small particles in the water as they pass under two transducers embedded in the insert (see Figure 1). These transducers monitor the particles in their respective beams. As the boat travels through the water, both transducers “view” the same stream of particles. Because it takes time for particles to travel between the two transducers, the aft transducer detects the particles later than does the fore transducer. By measuring this time lapse, the instrument calculates the boat speed.

The ultrasonic speed sensor requires particles in the water to obtain echoes. If the boat is airborne even for a short time or in highly aerated water, the sensor will measure an incorrect speed.

IMPORTANT: The ultrasonic speed sensor must be in good contact with the water at all times for the sensor to function properly.

CAUTION: NEVER USE SOLVENTS!

Cleaners, fuel, paint, sealants, and other products may contain strong solvents, such as acetone, which can attack many plastics greatly reducing their strength.

scanning transducer

hull

FORE AFT

vessel direction

particle stream

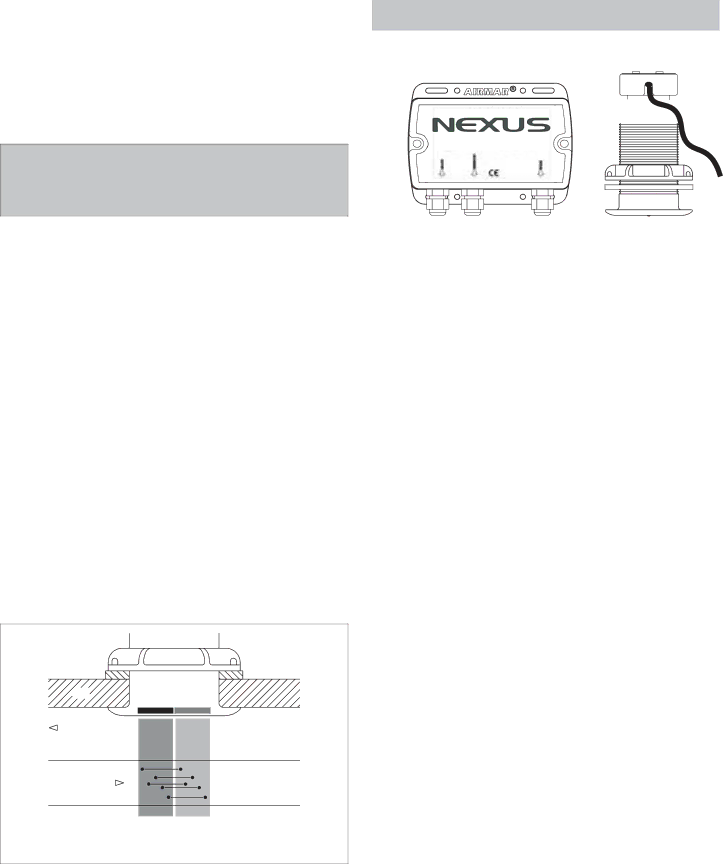

Figure 1. Monitoring particles in the water

Applications

•Not recommended for boats designed to pull air under the hull.

•Plastic housing recommended for fiberglass or metal hulls only. Never install a plastic sensor in a wood hull since swelling of the wood may overstress the plastic causing a fracture.

•Bronze housing recommended for fiberglass or wood hulls only. Never install a bronze housing in a metal hull because electrolytic corrosion will occur.

•Never install a metal housing in a vessel with a positive ground system.

•Ultrasonic insert must be installed in a housing with a valve. Raymarine

Tools and Materials

Safety goggles

Dust mask

Electric drill with 10mm or larger chuck capacity

Drill bit | 3mm or 1/8" |

Hole saw | 51mm or 2" |

Sandpaper |

|

Mild household detergent or weak solvent (such as alcohol)

File (installation in a metal hull)

Marine sealant

Additional washer [for aluminum hull less than 6mm (1/4") thick]

Installation in a cored fiberglass hull (see page 3):

Hole saw for hull interior | 60mm or |

Fiberglass cloth and resin

or Cylinder, wax, tape, and casting epoxy