Handling and Installation of Your TM Series Cooling Tower

On -Site Inspection

Upon arrival at the job site, carefully inspect the shipment for any damage. If shipping damage has occurred, notify the driver or the carrier immediately and make a notation of the damage on the shipping bill of lading. Check that all items listed B/L have been received.

Offloading

The TM Series cooling towers are normally delivered to the site on a 30 inch high drop deck trailer. Both the tower body assembly and sump assembly are strapped down to the truck bed. The sump assembly should be unloaded first.

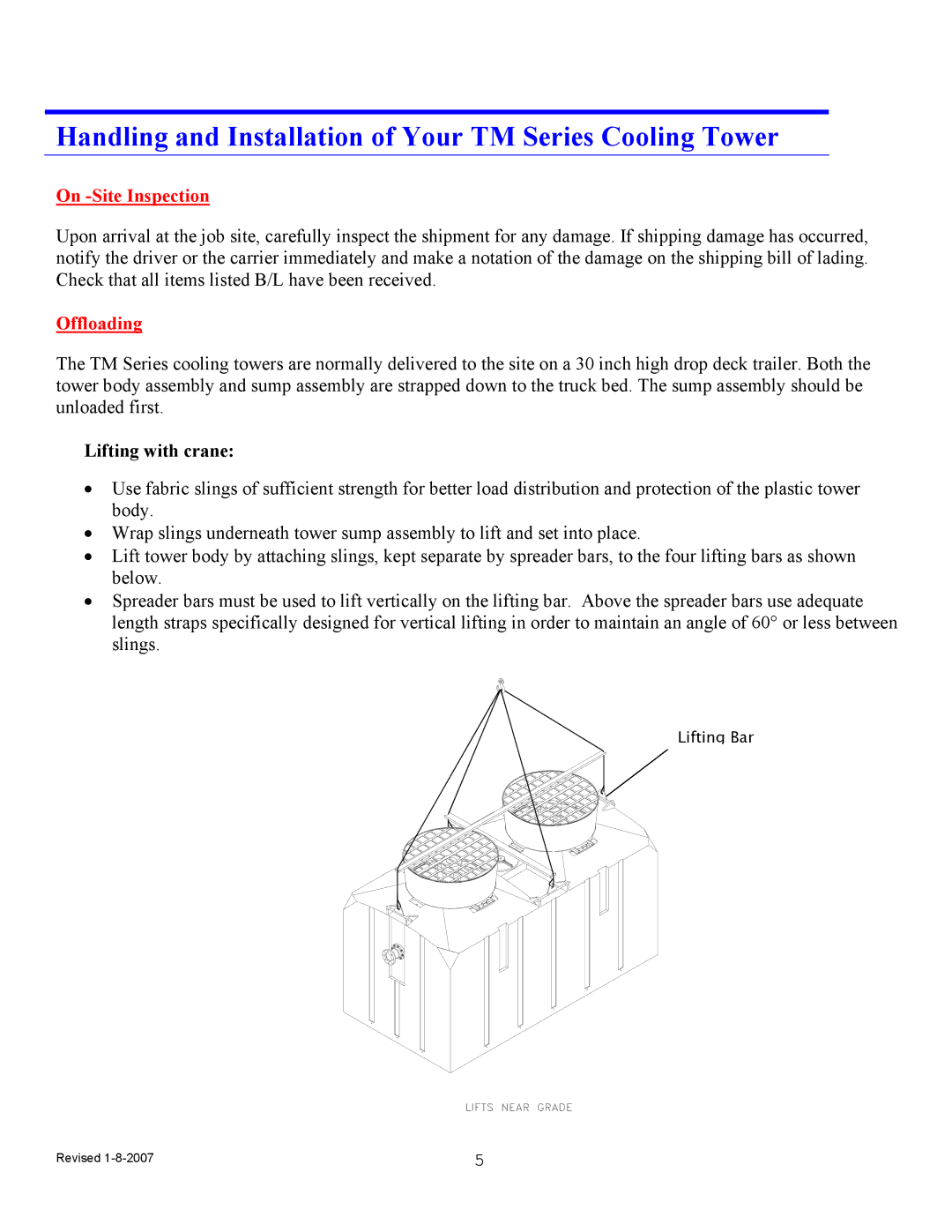

Lifting with crane:

•Use fabric slings of sufficient strength for better load distribution and protection of the plastic tower body.

•Wrap slings underneath tower sump assembly to lift and set into place.

•Lift tower body by attaching slings, kept separate by spreader bars, to the four lifting bars as shown below.

•Spreader bars must be used to lift vertically on the lifting bar. Above the spreader bars use adequate length straps specifically designed for vertical lifting in order to maintain an angle of 60° or less between slings.

Lifting Bar

Revised | 5 |