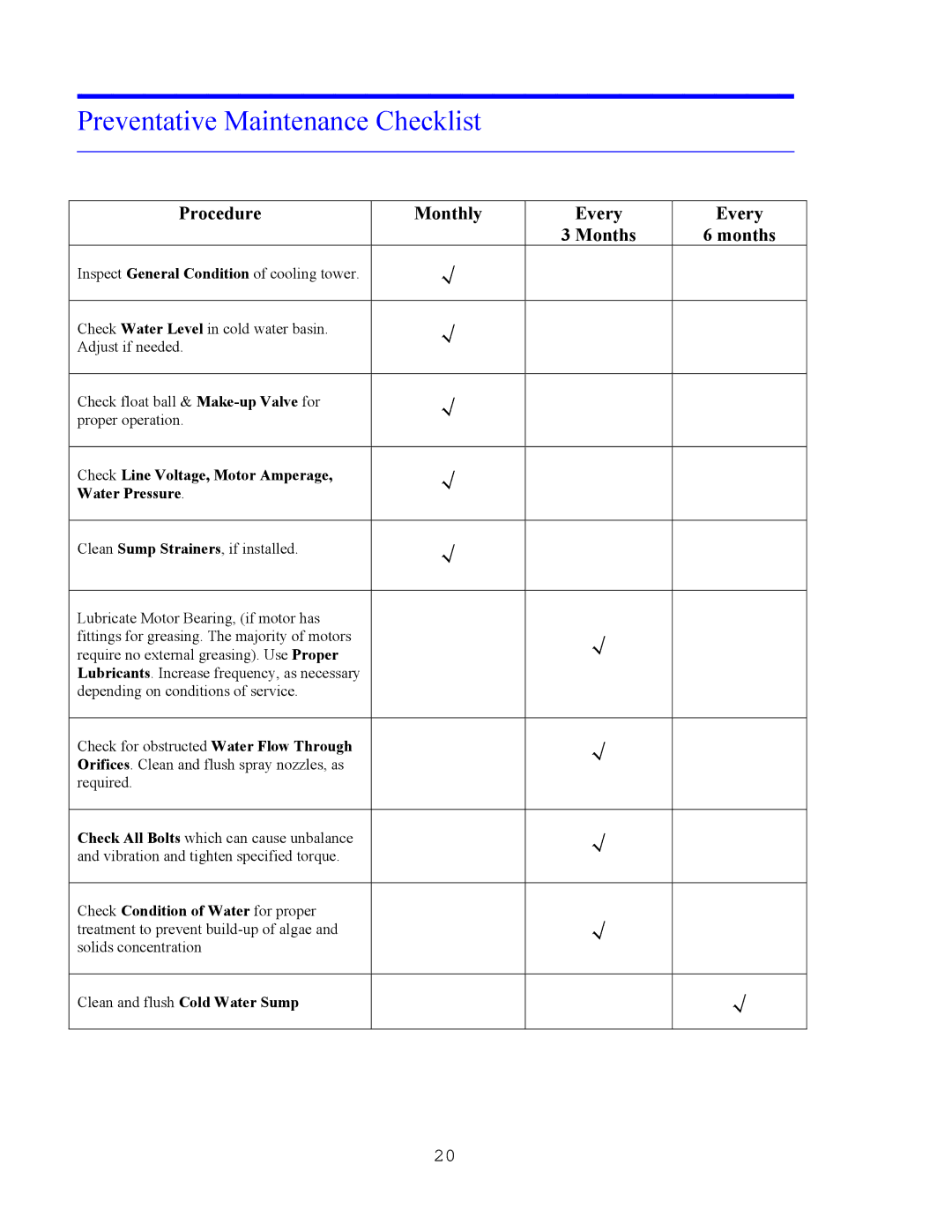

Preventative Maintenance Checklist

Procedure | Monthly | Every | Every |

|

| 3 Months | 6 months |

Inspect General Condition of cooling tower. | ¨ |

|

|

|

|

|

|

Check Water Level in cold water basin. | ¨ |

|

|

Adjust if needed. |

|

|

|

|

|

|

|

Check float ball & | ¨ |

|

|

proper operation. |

|

|

|

|

|

|

|

Check Line Voltage, Motor Amperage, | ¨ |

|

|

Water Pressure. |

|

|

|

|

|

|

|

Clean Sump Strainers, if installed. | ¨ |

|

|

|

|

|

|

Lubricate Motor Bearing, (if motor has |

|

|

|

fittings for greasing. The majority of motors |

| ¨ |

|

require no external greasing). Use Proper |

|

| |

Lubricants. Increase frequency, as necessary |

|

|

|

depending on conditions of service. |

|

|

|

|

|

|

|

Check for obstructed Water Flow Through |

| ¨ |

|

Orifices. Clean and flush spray nozzles, as |

|

|

|

required. |

|

|

|

|

|

|

|

Check All Bolts which can cause unbalance |

| ¨ |

|

and vibration and tighten specified torque. |

|

|

|

|

|

|

|

Check Condition of Water for proper |

|

|

|

treatment to prevent |

| ¨ |

|

solids concentration |

|

|

|

|

|

|

|

Clean and flush Cold Water Sump |

|

| ¨ |

|

|

|

|

20