Lubrication |

| Setting Fence Stops |

|

|

|

|

|

|

Follow all lubrication instructions outlined on Pages

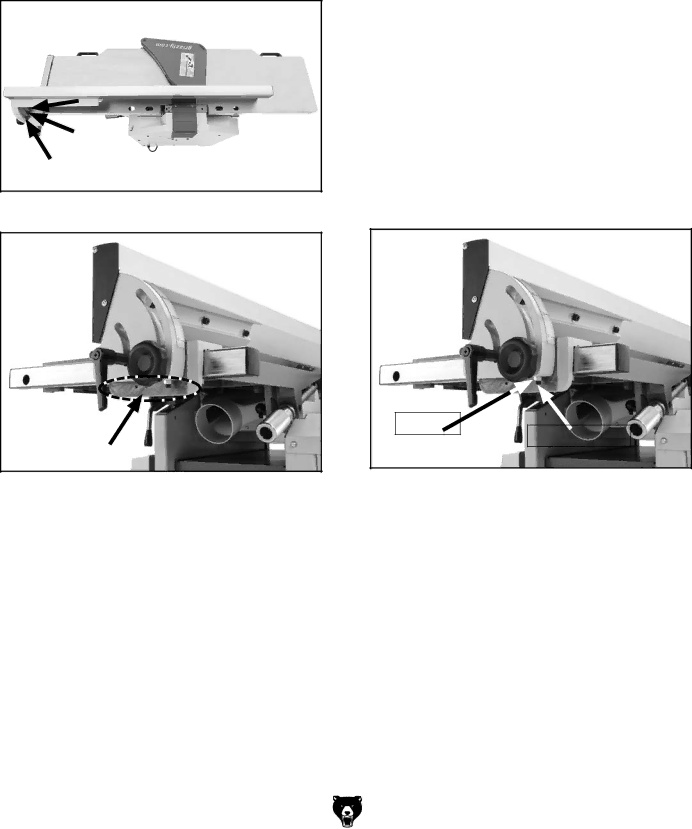

Figure 7. Inside fence lubrication locations.

The fence stops simplify the task of adjusting the fence to 45˚ and 90˚.

Tools Needed | Qty |

45° Square | 1 |

90° Square | 1 |

Sliding Bevel | 1 |

Wrench 10mm | 1 |

Wrench 12mm | 1 |

Hex Wrench 3mm | 1 |

Hex Wrench 4mm | 1 |

To set the 90˚ fence stop: |

|

1.Loosen the lock nut on the 90° fence stop screw shown in Figure 9, and loosen the fence tilt knob.